- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Unlocking Precision: The Ultimate Guide to Machining Centers for Advanced Manufacturing Techniques

In the rapidly evolving landscape of advanced manufacturing, the importance of machining centers cannot be overstated. According to a report by MarketsandMarkets, the global market for machining centers is projected to reach $90 billion by 2026, growing at a CAGR of 7.5% from 2021. This surge in demand highlights the critical role machining centers play in enhancing precision, efficiency, and productivity across various industries.

With their ability to perform multiple operations like milling, drilling, and turning in a single setup, machining centers have become indispensable for manufacturers aiming for high-quality output and reduced lead times. As the industry embraces automation and Industry 4.0 principles, understanding how to effectively leverage machining centers will be essential for companies aiming to stay competitive and innovate in today's market.

Understanding the Fundamentals of Machining Centers in Modern Manufacturing

Machining centers have become integral to modern manufacturing, serving as versatile solutions for high-precision tasks. According to a report by the International Federation of Robotics, the global market for machining centers is expected to surge, with a projected growth rate of 6% annually through 2025. This shift highlights the industry's move towards advanced manufacturing techniques that prioritize efficiency and accuracy. Understanding the fundamentals of machining centers is crucial for manufacturers aiming to stay competitive in today’s fast-paced market.

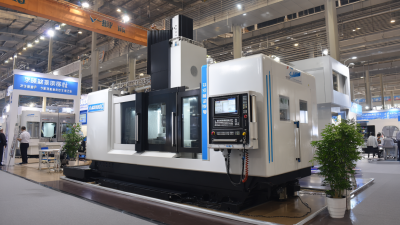

When selecting a machining center, consider the type of work being performed. For instance, vertical machining centers (VMCs) are ideal for producing complex parts with intricate features, while horizontal machining centers (HMCs) excel in high-volume production due to their efficiency in material handling. Remember to evaluate the spindle speed and tool changing capabilities, as these factors significantly affect overall productivity.

Tip: Regular maintenance and calibration of machining centers can enhance precision and prolong equipment lifespan. Implementing a proactive maintenance schedule not only prevents unexpected downtimes but also optimizes the quality of output, ensuring that manufacturing standards are consistently met. By understanding these fundamentals and applying best practices, manufacturers can unlock the full potential of machining centers in their operations.

Unlocking Precision: Machining Centers Usage in Advanced Manufacturing

Identifying Key Features and Specifications for Optimal Performance

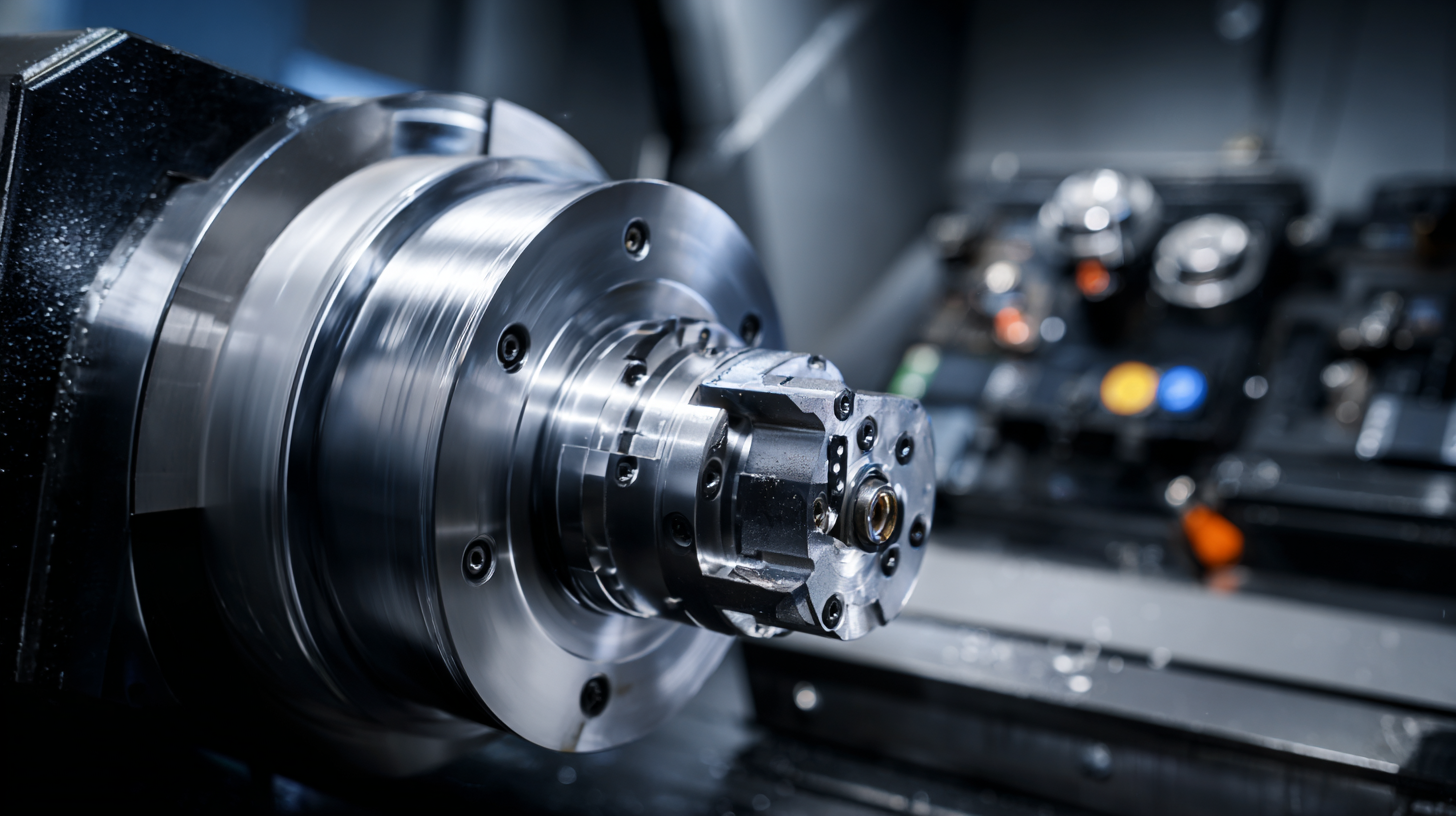

When selecting machining centers for advanced manufacturing techniques, understanding key features and specifications is crucial for achieving optimal performance. The drivetrain, spindle speed, and tool change capabilities are foundational elements that can differentiate high-performance machining centers from standard ones. A powerful spindle with high RPM can facilitate faster cutting speeds and improved precision, while robust tool change systems reduce downtime and enhance productivity. Additionally, consider the type of control system—CNC technology that supports advanced programming capabilities will significantly expand operational flexibility.

Another vital aspect revolves around the machine's rigidity and thermal stability. These factors influence the machining accuracy and lifespan of the equipment. A well-designed machining center minimizes thermal deformation and vibration, fostering a stable working environment that maintains precision. Furthermore, the configuration of the work envelope, including the range of motion and the ability to handle various workpiece sizes, plays a pivotal role in maximizing manufacturing capabilities. Ultimately, selecting a machining center with the right combination of features and specifications is essential for unlocking the full potential of advanced machining processes.

Another vital aspect revolves around the machine's rigidity and thermal stability. These factors influence the machining accuracy and lifespan of the equipment. A well-designed machining center minimizes thermal deformation and vibration, fostering a stable working environment that maintains precision. Furthermore, the configuration of the work envelope, including the range of motion and the ability to handle various workpiece sizes, plays a pivotal role in maximizing manufacturing capabilities. Ultimately, selecting a machining center with the right combination of features and specifications is essential for unlocking the full potential of advanced machining processes.

Selecting the Right Machining Center for Your Production Needs

Selecting the right machining center is pivotal for optimizing production efficiency and ensuring high-quality outputs in advanced manufacturing. When evaluating options, manufacturers should consider several key factors, including the type of materials processed, desired precision, and the complexity of the machining tasks. Understanding the specific requirements of production needs will guide the choice between horizontal, vertical, or multi-tasking machining centers, each offering distinct advantages depending on the application.

Additionally, exploring features such as control systems, spindle power, and tooling capabilities can significantly influence performance. For example, a machining center with a robust control system can enhance automation, ultimately leading to reduced cycle times and lower labor costs. Furthermore, assessing the available space and integration with existing systems is essential to ensure that the chosen machining center fits seamlessly into the production workflow. By focusing on these critical considerations, businesses can make informed decisions that align with their operational goals and technological advancements.

Unlocking Precision: The Ultimate Guide to Machining Centers for Advanced Manufacturing Techniques

| Machining Center Type | Axis Configuration | Max Table Load (kg) | Spindle Speed (RPM) | Positioning Accuracy (mm) | Price Range (USD) |

|---|---|---|---|---|---|

| Vertical Machining Center | 3-Axis | 1000 | 8000 | 0.01 | $50,000 - $100,000 |

| Horizontal Machining Center | 4-Axis | 1200 | 10000 | 0.015 | $80,000 - $150,000 |

| 5-Axis Machining Center | 5-Axis | 800 | 12000 | 0.005 | $150,000 - $300,000 |

| CNC Lathe | 2-Axis | 500 | 6000 | 0.02 | $30,000 - $70,000 |

Implementing Advanced Techniques for Enhanced Precision and Efficiency

The implementation of advanced manufacturing techniques plays a crucial role in enhancing precision and efficiency in machining centers. According to recent reports from the National Institute of Standards and Technology (NIST), integrating technologies such as Computer Numerical Control (CNC) and automation can increase production precision by up to 25%. These advancements not only allow for tighter tolerances but also significantly reduce human error, leading to more consistent product quality.

Moreover, the adoption of advanced techniques like additive manufacturing and subtractive machining combinations has demonstrated a remarkable impact on operational efficiency. A study by the MIT Center for Advanced Manufacturing revealed that facilities utilizing hybrid machining processes saw an increase in throughput by 30%, while simultaneously lowering raw material waste by approximately 15%. This shift not only optimizes the use of resources but also contributes to a more sustainable production environment, ultimately driving profitability and competitiveness in the market.

Maintaining and Troubleshooting Your Machining Center for Longevity

Maintaining and troubleshooting machining centers is essential for ensuring their longevity and optimal performance. Reports indicate that improper maintenance can lead to significant downtime, which can cost manufacturers an estimated $5,000 to $15,000 per hour in productivity loss. Routine inspections, correct lubrication, and timely replacements of worn components are vital practices that can prevent costly repairs and extend the life of these complex machines.

Furthermore, advanced manufacturing techniques increasingly leverage data-driven insights. According to a recent study by the American Society of Mechanical Engineers, the integration of predictive maintenance analytics can reduce machinery downtime by up to 30%. Implementing such strategies allows manufacturers to anticipate failures before they occur, thereby streamlining operations and enhancing overall efficiency. Proper training for operators on troubleshooting methods and understanding machine notifications is also critical, as misinterpretation can lead to unnecessary repairs or prolonged downtimes.

Related Posts

-

How to Choose the Right Machining Center for Your Manufacturing Needs

-

Exploring Innovations in Vertical Machining Centers at the 138th Canton Fair 2025: A Data-Driven Perspective

-

Discover How Best Precision Machining from China Leads Global Manufacturing Excellence

-

Understanding Global Industry Standards for Best CNC Machining Precision Production

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

-

7 Secrets to Finding the Best CNC Precision Machining Suppliers Worldwide