- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Unlocking Precision Engineering with the Power of 3 Axis Milling Machines

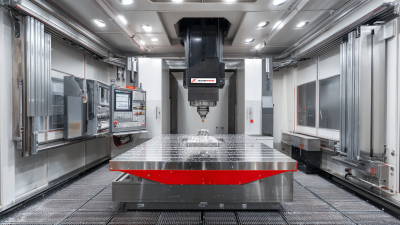

In today’s competitive manufacturing landscape, precision engineering stands as a critical component for industries seeking to enhance their product quality and efficiency. Among the various tools available, the 3 axis milling machine has emerged as a cornerstone for achieving high levels of accuracy and versatility in machining processes. This introduction will delve into the essential features and operational methodologies associated with 3 axis milling machines, illustrating their significance in streamlining workflow and optimizing production capabilities.

As we explore the intricacies of utilizing these machines, we will provide practical insights and step-by-step guidance that empower engineers and manufacturers to unlock the full potential of 3 axis milling technology. Whether you are a seasoned professional or new to the field, understanding how to effectively leverage 3 axis milling machines can revolutionize your approach to precision engineering, making it an indispensable asset in modern manufacturing practices.

Exploring the Advantages of 3 Axis Milling Machines in Precision Engineering

The rise of 3-axis milling machines in precision engineering has significantly transformed the manufacturing landscape, offering unparalleled advantages that enhance productivity and accuracy. A report from Research and Markets indicates that the global CNC milling machine market is projected to reach $80.23 billion by 2026, indicating a steady demand driven by advancements in machining technology. 3-axis milling machines, known for their ability to deliver precise cuts and complex geometries, play a pivotal role in various industries, from aerospace to medical devices.

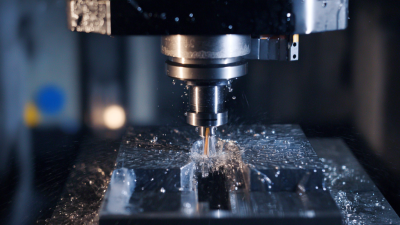

One of the key advantages of 3-axis milling machines is their versatility in handling a wide range of materials, including metals, plastics, and composites. This adaptability allows manufacturers to streamline operations, as one machine can perform multiple tasks—such as drilling, milling, and contouring—reducing the need for extensive tooling and setups. According to a study by MarketsandMarkets, the operational efficiency gained through the use of 3-axis systems can lead to a time reduction of up to 50% in production cycles, thereby enhancing overall manufacturing throughput while maintaining high standards of quality and precision.

Key Features of 3 Axis Milling Machines That Enhance Productivity

The landscape of precision engineering is rapidly transforming with the increasing adoption of 3 axis milling machines, which are pivotal in enhancing productivity across various industries. The integration of advanced digital manufacturing technologies has led to significant advancements in workflow efficiency. Notably, the global CNC machine tools market is projected to grow by $21.9 billion between 2025 and 2029, driven by the soaring demand for high-precision, multi-axis machining centers. This growth highlights the crucial role of innovative machinery in meeting the industry's evolving needs.

Key features of 3 axis milling machines contribute directly to productivity improvements in manufacturing processes. These machines deliver exceptional accuracy and efficiency, enabling manufacturers to reduce cycle times while increasing the quality of finished products. PTC's recent addition to its cloud-native Onshape features facilitates enhanced collaboration between design and production teams, ensuring that project timelines are met with efficiency. As the end milling machine market is expected to reach an estimated value of $57.3 billion by 2025, it underscores the significance of embracing cutting-edge technology to stay competitive in the manufacturing sector.

Applications of 3 Axis Milling Machines in Various Industries

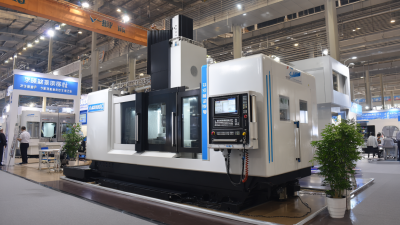

The application of 3-axis milling machines spans a wide array of industries, from aerospace to automotive, significantly enhancing production efficiency and precision. These machines are renowned for their ability to execute complex designs with high accuracy, making them essential for manufacturing parts with intricate geometries. According to a market research study published by Custom Market Insights, the global CNC metal milling machine market is projected to witness a steady growth rate, with a CAGR of 5.1%. This growth reflects the increasing adoption of 3-axis milling technology across various sectors.

In the automotive industry, for instance, 3-axis milling machines are pivotal in the production of engine components and structural parts, allowing for precise machining that meets stringent quality standards. Similarly, in the aerospace sector, the precision and reliability of 3-axis milling are crucial for the fabrication of lightweight yet durable components. The versatility of these machines enables manufacturers to handle diverse materials, catering to the specific needs of various applications. As the demand for high-precision manufacturing continues to rise, the role of 3-axis milling machines will likely expand, driving innovation and efficiency in multiple industrial domains.

Comparative Analysis: 3 Axis Milling vs. 5 Axis Milling Technology

In the realm of precision engineering, the debate between 3 axis milling and 5 axis milling technology remains a pivotal consideration for manufacturers. According to a report by the Global Market Insights, the demand for 3 axis milling machines is projected to reach a valuation of $3 billion by 2025, showcasing their continued relevance in the machining sector. These machines, with their straightforward operation and cost efficiency, are particularly favored for projects involving simple geometries and quick turnaround times. Their capacity for producing high-fidelity components with excellent surface finish at a lower initial investment makes them an attractive option for small to medium enterprises.

On the other hand, 5 axis milling technology offers a distinct advantage in terms of complex part fabrication. Industry experts suggest that this technology can reduce setup times by up to 30% and improve machining accuracy by allowing more intricate designs to be completed in a single operation. This capability aligns with the increasing trend towards customization in manufacturing, where complex geometries are increasingly in demand. Market research from Technavio indicates that the 5 axis milling market is expected to grow at a CAGR of 6% through 2027, reflecting a significant shift towards advanced milling solutions. In summary, while 3 axis milling remains fundamental for many applications, the expansion of 5 axis technology signals a clear direction for the future of precision engineering.

Future Trends in 3 Axis Milling Machines and Precision Engineering

As industries evolve, the significance of precision engineering supported by advanced milling machines is becoming increasingly evident. Recent market analysis by Industry Research revealed that the global 3 axis milling machine market is expected to reach USD 2.8 billion by 2025, driven by innovations in automation and CNC technology. These machines are essential for industries such as aerospace and automotive, where precision is paramount. Future trends indicate a shift towards smart milling systems integrated with AI and IoT, which will not only enhance efficiency but also reduce operational costs by up to 30%.

Tips: When selecting a 3 axis milling machine, consider models with real-time monitoring systems to enhance your production accuracy. Staying updated with software advancements can also provide a significant edge in maximizing your machine's potential.

Looking ahead, the rise of additive manufacturing technologies is set to reshape the landscape of precision engineering. Combining traditional machining processes with 3D printing can significantly shorten lead times, as highlighted in a report by MarketsandMarkets, forecasting a compound annual growth rate (CAGR) of 24.9% in this sector through 2026. Embracing these innovations will not only optimize existing processes but also pave the way for unprecedented design capabilities.

Tips: Regularly evaluate your production workflows to identify areas where integration of new technologies can yield improved outcomes. This proactive approach can ensure your operations remain competitive in an evolving market.

Unlocking Precision Engineering with the Power of 3 Axis Milling Machines

| Feature | Current Trend | Future Outlook | Impact on Precision Engineering |

|---|---|---|---|

| Automation | Increased use of CNC technology | Fully automated 3D milling processes | Higher efficiency and reduced human error |

| Materials | Usage of advanced composite materials | Enhanced material selection for aerospace and automotive | Improved performance and weight reduction |

| Software | Integration of CAD/CAM software | Real-time simulation and optimization tools | Streamlined design to production workflow |

| Precision | Focus on micron-level precision | Developments in micro-milling technology | Expanded applications in medical and electronics |

| Sustainability | Increased energy efficiency measures | Greener manufacturing processes | Lower carbon footprint in production |

Related Posts

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

-

How to Enhance Precision and Efficiency with 3 Axis CNC Milling Machines in Modern Manufacturing

-

Exploring Innovations in Vertical Machining Centers at the 138th Canton Fair 2025: A Data-Driven Perspective

-

How to Optimize Your Workflow with a 5 Axis Milling Machine