- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Top 10 Tips for Choosing the Best Machining Center for Your Needs

When it comes to selecting the ideal machining center for your business, the decision can be daunting given the plethora of options available on the market. As industry expert John Doe aptly states, “Choosing the right machining center is crucial for maximizing efficiency and ensuring quality output in manufacturing processes.” This insight highlights the importance of making informed choices when it comes to investing in machining centers that align with specific operational needs.

Understanding the various features, capabilities, and specifications of machining centers is essential before making a purchase. Factors such as size, spindle speed, tooling options, and ease of automation play a significant role in determining the best fit for your shop floor. Moreover, the investment in a machining center is not just about the initial cost, but also about its long-term benefits, adaptability to future demands, and the support you'll receive post-purchase.

As you embark on this journey to find the perfect machining center, keep in mind that assessing your production requirements is paramount. The right machining center can greatly enhance your manufacturing process, improve precision, and ultimately provide a competitive edge in an ever-evolving market.

Understanding Your Machining Needs and Specifications

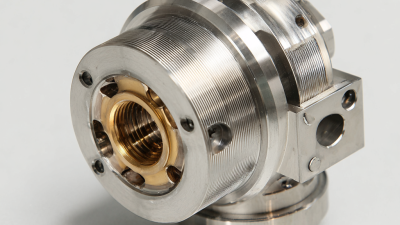

When selecting the ideal machining center for your operations, a clear understanding of your specific machining needs and specifications is paramount. Begin by assessing the materials you will be working with, such as metals, plastics, or composites, as this will influence the type of machining processes you require. Different materials demand varied cutting speeds, feeds, and tooling, so matching your machining center to the characteristics of your materials can significantly enhance efficiency and quality.

Additionally, evaluate the complexity and precision of the parts you intend to manufacture. Consider the dimensions, tolerances, and any intricate features that may require advanced tooling or multi-axis capabilities. A machining center designed for high precision might be essential for complex geometries. Understanding your production volume is also critical; whether you’re engaged in low-volume, high-mix production or high-volume manufacturing will guide your choice of features such as automation options and cycle times. By clearly defining your requirements, you can make an informed decision that aligns with your operational goals and maximizes productivity.

Evaluating Different Types of Machining Centers Available

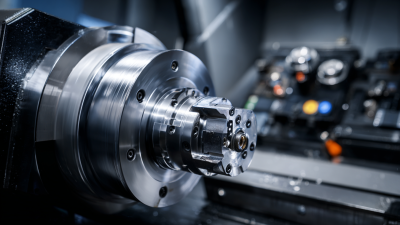

When evaluating different types of machining centers available, it’s essential to understand the specific requirements of your operations. There are vertical and horizontal machining centers, each catering to different needs. Vertical machining centers are generally more versatile and suited for small to medium-sized components, offering better visibility and easier setup. In contrast, horizontal machining centers excel in production settings with larger parts, providing enhanced stability and efficient chip removal.

Tip 1: Assess the size of the workpieces you'll be machining. This will guide you in choosing a machining center that can accommodate your parts effectively, preventing the need for additional investments later on.

Another significant factor to consider is the complexity of the parts you intend to produce. If your components require multi-axis machining, investing in a 5-axis machining center might be the best option. This machinery allows for the intricate production of complex geometries without the need for multiple setups, which can save both time and resources.

Tip 2: Evaluate the machine's tooling capabilities. Ensure that the machining center you choose can support the variety of tooling necessary for your applications, as this can impact the overall efficiency and flexibility of your production process.

Top 10 Tips for Choosing the Best Machining Center for Your Needs

| Feature | VMC (Vertical Machining Center) | HMC (Horizontal Machining Center) | 5-Axis Machining Center | Router |

|---|---|---|---|---|

| Best for | 2D and 3D shapes | Complex parts requiring high precision | Multi-sided parts and intricate designs | Flat panel materials and plastics |

| Typical Workpiece Size | Small to medium | Medium to large | Small to large | Small |

| Cost Range | $50,000 - $150,000 | $75,000 - $250,000 | $100,000 - $500,000 | $30,000 - $100,000 |

| Speed | Moderate | High | Very High | High |

| Ease of Use | Easy | Moderate | Complex | Very Easy |

| Common Applications | Automotive, Aerospace | Aerospace, Defense | Medical, Automotive | Sign making, Furniture |

| Maintenance Needs | Low | Moderate | High | Low |

Key Features to Consider When Choosing a Machining Center

When choosing a machining center, understanding the key features that align with your specific production needs is crucial. One of the primary considerations should be the machine's size and capacity. The machining center should accommodate the dimensions of your workpieces and the scale of your operations. Additionally, evaluate the spindle speed and horsepower, as these factors directly influence the machining speed and the ability to handle various materials efficiently. A higher spindle speed often translates to increased productivity, particularly for complex projects requiring precision.

Another vital feature to examine is the tool magazine and the tool change time. A machining center with a larger tool capacity and faster change capabilities can significantly enhance operational efficiency, especially when dealing with a diverse array of parts requiring multiple tooling setups. Additionally, consider the level of automation available, such as pallet changers or tool management systems, which can further optimize workflow and minimize downtime. An effective combination of these features will ensure that you choose a machining center that not only meets your current requirements but also adapts to future production challenges.

Top 10 Tips for Choosing the Best Machining Center

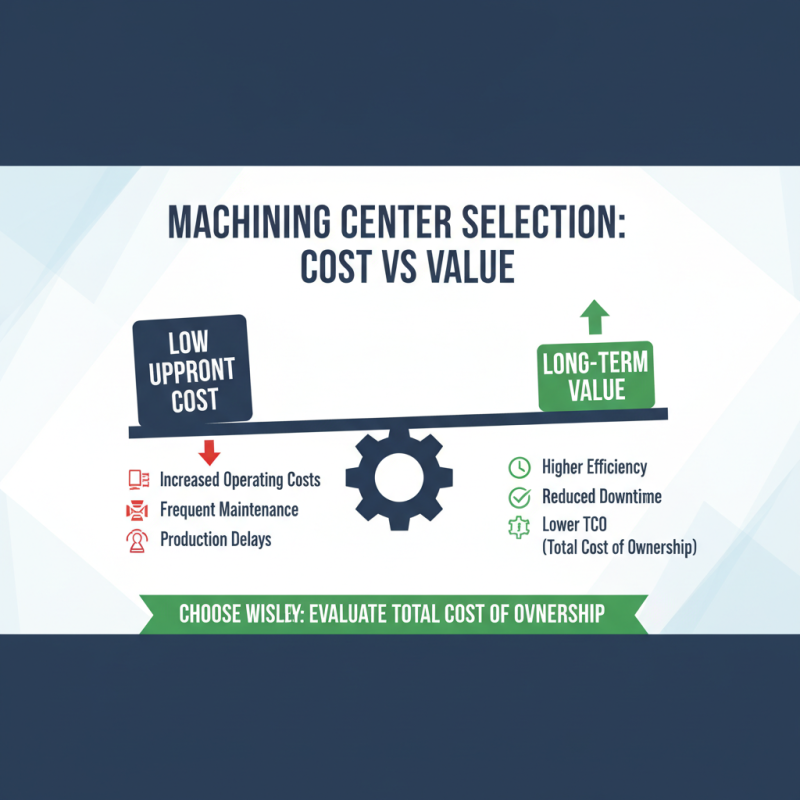

Analyzing Cost vs. Value in Your Machining Center Selection

When selecting a machining center, it is essential to carefully analyze the balance between cost and value. A lower upfront cost may seem appealing, but it’s vital to consider the long-term implications of that choice. Often, budget machines can lead to increased operation costs, frequent maintenance issues, and potential production delays, which ultimately diminish their initial cost advantage. Therefore, evaluating the total cost of ownership, including maintenance, downtime, and efficiency, is crucial in the decision-making process.

Value in machining centers goes beyond just the sticker price; it encompasses features such as precision, versatility, and reliability. Investing in a higher-quality machine may yield better performance, reduced scrap rates, and enhanced operational capabilities, which can lead to higher profit margins over time. Additionally, consider the machine's adaptability to future projects and technological advancements. This foresight can further justify the investment by ensuring that the machining center remains relevant and efficient as demands change. In essence, careful consideration of both cost and value is vital for making a choice that will support your operational needs and business growth in the long run.

Determining Support and Maintenance Options for Your Machinery

When selecting a machining center, one critical aspect that cannot be overlooked is the support and maintenance options available for the machinery. According to a report by the Association for Manufacturing Technology, up to 25% of total operational costs in machining centers can be attributed to maintenance and support services. Therefore, understanding the types of service contracts and maintenance plans can significantly impact overall efficiency and longevity of the equipment.

It's essential to evaluate the types of support provided by the manufacturer or supplier. Options such as 24/7 technical support, on-site repairs, and preventive maintenance programs can drastically reduce downtime. A survey conducted by the Manufacturing Institute revealed that companies utilizing comprehensive support services experienced a 30% decrease in unplanned downtimes compared to those relying on standard service options. By investing in robust support and maintenance strategies, manufacturers can enhance productivity and safeguard their investment in advanced machining technology.

Additionally, consider the availability of training for operators and maintenance personnel. A well-trained team can effectively manage routine upkeep and swiftly address minor issues before they escalate. Research indicates that organizations that implement regular training sessions see improvements in machine performance and a reduction in maintenance costs by approximately 20%. By prioritizing support and maintenance options, managers can not only optimize their machining center's operations but also ensure a higher return on their investment.

Related Posts

-

Unlocking Precision: The Ultimate Guide to Machining Centers for Advanced Manufacturing Techniques

-

How to Choose the Right Machining Center for Your Manufacturing Needs

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Unlocking Precision: The Essential Guide to 5 Axis Milling Machines for Modern Manufacturing

-

5 Reasons High Speed CNC Machining Can Boost Your Production Efficiency by 50 Percent

-

Unleashing China's Premier CNC Machining for Global Market Leadership