- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

7 Secrets to Finding the Best CNC Precision Machining Suppliers Worldwide

In today's highly competitive manufacturing landscape, the demand for high-quality CNC precision machining has surged, underscoring the importance of selecting the right suppliers. According to a recent report by Grand View Research, the CNC machining market is projected to reach $103.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.9%. This growth is largely driven by advancements in technology and the increasing adoption of CNC machines across various industries, including aerospace, automotive, and electronics. As businesses seek to enhance their production efficiency and product quality, finding reliable CNC precision machining suppliers becomes critical. This blog will unveil seven essential secrets to help manufacturers locate the best CNC precision machining suppliers worldwide, ensuring they can maintain a competitive edge in their respective markets.

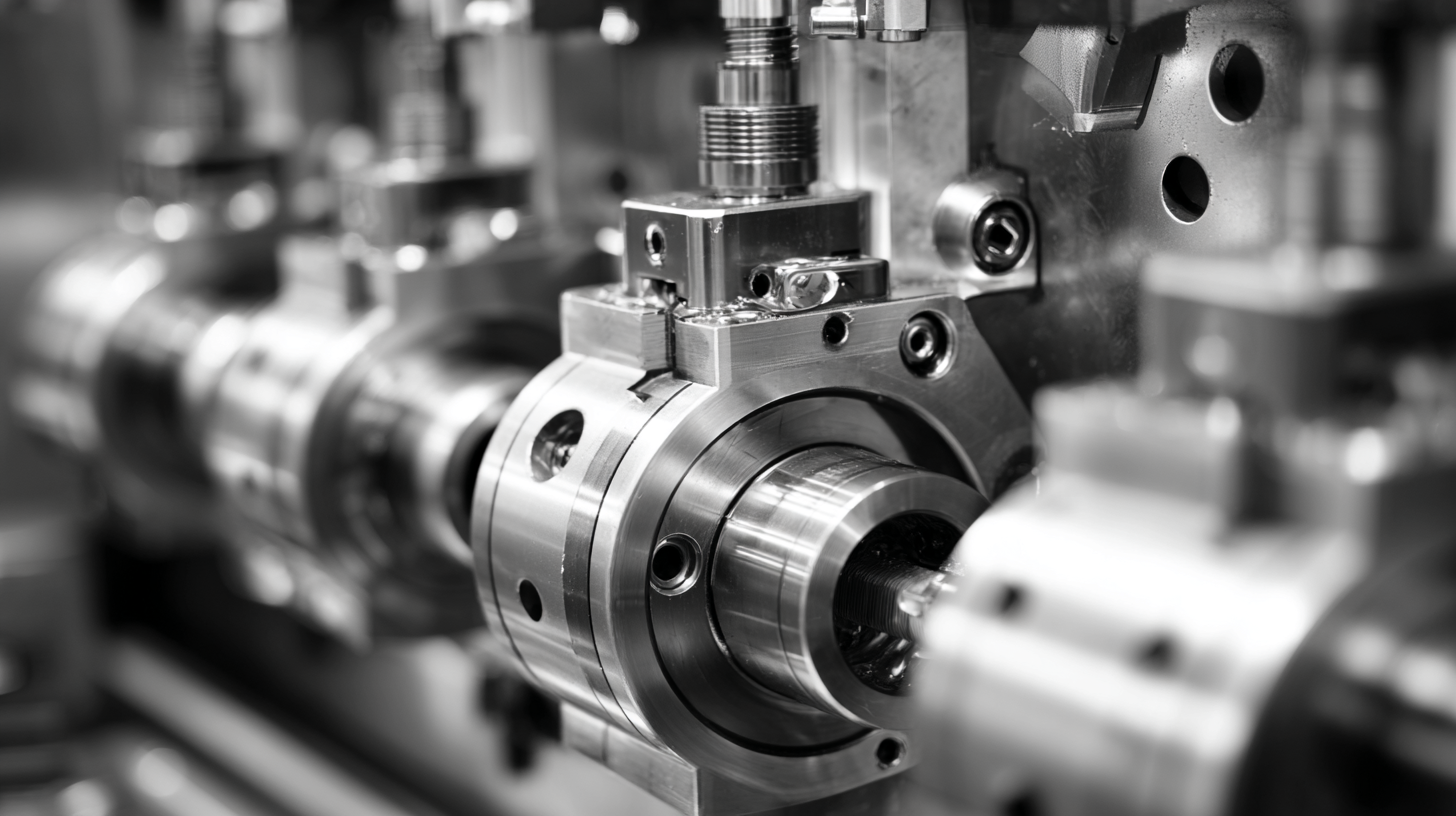

Understanding CNC Precision Machining and Its Importance in Modern Manufacturing

CNC precision machining plays a pivotal role in modern manufacturing, serving as the backbone for producing high-quality parts across various industries. As the global machine tool market is projected to grow from $13.63 billion in 2025 to $22.94 billion by 2032, with a compound annual growth rate (CAGR) of 8.1%, the demand for precision machining suppliers is set to skyrocket. This growth underscores the importance of CNC technology, which allows for remarkable accuracy and efficiency in the production process, essential for maintaining competitive advantage in today’s fast-paced manufacturing landscape.

Additionally, advancements in electric spindle technology, with investments such as the recent $7.68 million funding in domestic manufacturing firms, highlight the ongoing innovations in this sector. As countries strive to close the technological gap, particularly with established leaders like Japan, there is a pressing need to emphasize research and development as well as equipment innovation. The commitment to advancing CNC precision machining technology not only supports the rise of national brands but also exemplifies the entrepreneurial spirit driving the industry towards a brighter future.

7 Secrets to Finding the Best CNC Precision Machining Suppliers Worldwide

| Supplier Location | Machining Capabilities | Quality Certifications | Lead Time (Days) | Customer Rating (out of 5) |

|---|---|---|---|---|

| USA | CNC Milling, Turning, Grinding | ISO 9001, AS9100 | 10 | 4.5 |

| Germany | CNC Machining, Electrical Discharge Machining | ISO 9001, TS16949 | 15 | 4.7 |

| China | CNC Milling, Laser Cutting | ISO 9001, ISO 13485 | 20 | 4.2 |

| Japan | CNC Turning, EDM, 3D Printing | JIS Q 9001, ISO 14001 | 12 | 4.8 |

| South Korea | CNC Machining, Injection Molding | ISO 9001, IATF 16949 | 8 | 4.6 |

Key Features to Look for in Top CNC Machining Suppliers

When searching for the best CNC precision machining suppliers worldwide, it's essential to focus on key features that set top companies apart. First and foremost, look for suppliers with advanced technology and modern equipment. High-quality CNC machines ensure accuracy, efficiency, and the ability to produce complex designs with tight tolerances.

In addition, ensure that the supplier has a robust quality control system in place. Certifications such as ISO 9001 can indicate a commitment to quality and reliability.

Another crucial aspect to consider is the supplier's experience and expertise in your specific industry. A knowledgeable CNC machining supplier understands the unique challenges and requirements of different sectors, be it aerospace, automotive, or medical. This specialized knowledge can significantly enhance the outcome of your projects. Additionally, evaluate the supplier's customer service and responsiveness. A company that prioritizes communication and support is invaluable, especially when adjustments or rapid turnarounds are needed. By focusing on these key features, you can confidently identify the best CNC machining partners to meet your production demands.

How to Evaluate the Quality of CNC Machining Services

When evaluating the quality of CNC machining services, start by examining the supplier's credentials and experience in the industry. A reputable supplier should have a portfolio showcasing their previous work along with certifications that reflect adherence to industry standards, such as ISO 9001. Checking reviews and testimonials can provide insights into their reliability and the satisfaction of previous clients. Additionally, ensure that they possess modern machinery and technology, as this can significantly impact the precision and efficiency of their machining capabilities.

Another crucial factor in assessing CNC machining services is communication and customer support. A supplier that values open communication is more likely to understand your specific needs and can adjust their processes accordingly. Gauge their responsiveness during initial interactions—prompt reactions to inquiries indicate a commitment to customer service. Lastly, discuss their quality control measures. A robust quality assurance process, including regular inspections and testing, is essential for delivering consistent, high-quality components that meet your specifications.

7 Secrets to Finding the Best CNC Precision Machining Suppliers Worldwide

The Role of Technology in Enhancing CNC Precision Machining Efficiency

In the realm of CNC precision machining, technology plays a pivotal role in enhancing efficiency and accuracy. Advanced software such as CAD and CAM systems streamline the design and production processes, reducing the likelihood of errors and minimizing waste. By automating various stages of machining, manufacturers can not only increase throughput but also maintain consistent quality across batches. This integration of technology into machining workflows ensures that suppliers can meet the precise needs of their clients while maintaining cost-effectiveness.

To find the best CNC precision machining suppliers, consider leveraging technology in your search. Utilize online platforms that aggregate supplier reviews and ratings, helping you identify reputable companies quickly. Additionally, employ virtual consultations and tours to explore suppliers' facilities and capabilities. This not only saves time but also aids in forming clear communication channels, critical for collaborative projects.

To find the best CNC precision machining suppliers, consider leveraging technology in your search. Utilize online platforms that aggregate supplier reviews and ratings, helping you identify reputable companies quickly. Additionally, employ virtual consultations and tours to explore suppliers' facilities and capabilities. This not only saves time but also aids in forming clear communication channels, critical for collaborative projects.

Another critical tip is to look for suppliers that are continuously investing in technology upgrades. Suppliers that adopt the latest CNC machining tools and techniques are better positioned to handle complex tasks and deliver high-quality products. By prioritizing technology-driven suppliers, you can ensure that your project's specifications are met while also benefiting from improved lead times and innovative solutions.

Building Long-Term Relationships with CNC Precision Machining Suppliers

Building long-term relationships with CNC precision machining suppliers is essential for companies looking to enhance their manufacturing capabilities. The key lies in establishing trust and open communication with suppliers. By sharing your vision, project requirements, and expectations, you can foster a collaborative environment that encourages innovation and problem-solving. Regular feedback sessions and transparent discussions about challenges can strengthen these partnerships, enabling both parties to adapt and grow together.

In today’s competitive market, suppliers who embrace advanced technologies are increasingly vital. As new players emerge and existing companies expand into sectors like aerospace and engineering, keeping an eye on their capabilities and growth strategies is crucial. For instance, recent companies entering the IPO market with ambitious plans signal a shift towards diversification and technological advancement. Aligning with such forward-thinking suppliers can offer your business more than just parts; it can provide a pathway to collaborative innovation that enhances your product offerings and market competitiveness. Investing time in nurturing these relationships will ultimately pay off in increased efficiency and shared success.