- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Top 10 Precision CNC Machining Techniques for Maximum Efficiency and Accuracy

In the rapidly evolving landscape of manufacturing, precision CNC machining has emerged as a cornerstone for achieving both efficiency and accuracy. According to Dr. Emily Chang, a leading expert in CNC technology, “The key to maximizing production lies in mastering precision CNC machining techniques.” This highlights the crucial role that precision plays in not only meeting but exceeding production standards in various industries, from aerospace to medical devices.

As manufacturers strive to enhance their operational efficiency, understanding and implementing the top precision CNC machining techniques becomes essential. These techniques not only improve precision but also reduce waste and downtime, ultimately leading to higher profitability. By focusing on refining processes such as tool path optimization, advanced material selection, and machine calibration, companies can ensure that they stay competitive in an increasingly demanding market.

This article delves into the top 10 precision CNC machining techniques that can significantly impact productivity and product quality. By exploring these methods, manufacturers can gain valuable insights into how to leverage precision CNC machining for optimal results, paving the way for innovation and success in their respective fields.

Understanding CNC Machining: An Overview of Precision Techniques

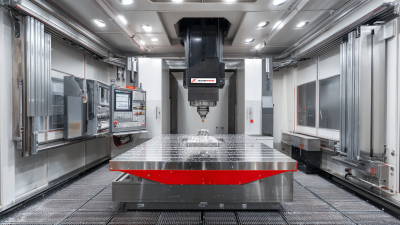

CNC machining, or Computer Numerical Control machining, revolutionizes precision manufacturing by automating the tools that shape parts and components. At its core lies an intricate interplay of advanced technology and meticulous programming that allows for highly accurate machining operations. This technology not only enhances the efficiency of machining processes but also reduces human error, which is pivotal in achieving consistent quality across numerous production runs. Understanding the fundamentals of CNC machining is essential for anyone involved in manufacturing, as it lays the groundwork for employing various precision techniques effectively.

Among the precision techniques utilized in CNC machining, multi-axis machining stands out for its ability to cut complex shapes with unparalleled accuracy. This method employs multiple axes of movement, enabling machines to approach the workpiece from various angles, thus allowing for intricate designs that were once difficult to achieve. Another vital technique is the use of tooling adaptations, which ensures that the right tool is always aligned with the material being processed, leading to optimal performance and surface finish. By mastering these and other precision techniques, manufacturers can boost their productivity and deliver high-quality components that meet the stringent requirements of today's industries.

The Importance of Material Selection in CNC Machining Efficiency

Material selection plays a crucial role in the efficiency and accuracy of CNC machining. The characteristics of the material chosen can significantly influence the machining process, affecting factors such as tool wear, cutting speed, and overall production time. For instance, materials with high hardness may require more robust tooling and slower feed rates, increasing cycle times and wear on equipment. Conversely, softer materials can often be machined at higher speeds, leading to enhanced productivity and reduced costs. Understanding the physical and mechanical properties of materials is therefore paramount in tailoring machining parameters for optimum performance.

Moreover, the right material can reduce the likelihood of defects and rework, which are detrimental to both efficiency and cost-effectiveness. Selecting materials that are compatible with the specific CNC machining techniques being employed ensures smoother operations and better end-product quality. Additionally, considerations such as thermal conductivity, machinability, and surface finish should guide the material selection process, as they directly impact the precision of the final components. By prioritizing material selection, manufacturers can not only streamline their machining processes but also maximize the accuracy of their outputs, leading to enhanced competitiveness in the market.

Top 10 Precision CNC Machining Techniques for Maximum Efficiency and Accuracy

| Technique | Description | Material Type | Efficiency Rating | Accuracy Rating |

|---|---|---|---|---|

| Turning | A machining process used to create cylindrical parts. | Aluminum | 8/10 | 9/10 |

| Milling | A process that removes material using rotary cutters. | Steel | 9/10 | 8/10 |

| Drilling | Creating round holes in a workpiece. | Brass | 7/10 | 9/10 |

| Electrical Discharge Machining (EDM) | Uses electrical discharges to cut and shape conductive materials. | Titanium | 8/10 | 10/10 |

| Laser Cutting | Utilizes a laser to cut materials with high precision. | Carbon Steel | 10/10 | 9/10 |

| Waterjet Cutting | A technique that uses high-pressure water to cut materials. | Glass | 9/10 | 8/10 |

| 3D Printing | Additive manufacturing process to create complex shapes. | Plastic | 8/10 | 7/10 |

| Grinding | Utilizes an abrasive wheel to achieve a high finish. | Ceramics | 8/10 | 9/10 |

| CNC Routing | A subtractive manufacturing process used for cutting and shaping materials. | Plywood | 9/10 | 8/10 |

Exploring Advanced Tooling Options for Enhanced Accuracy in CNC Processes

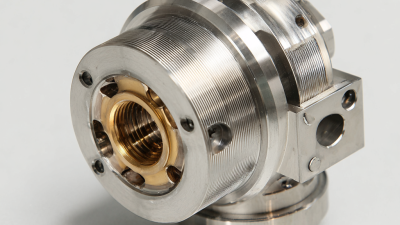

Advanced tooling options play a crucial role in enhancing accuracy in CNC processes, pushing the boundaries of precision machining. One of the leading trends in this area is the adoption of high-performance cutting tools that are specifically designed for efficiency. These tools often feature specialized coatings that reduce friction and wear, allowing them to maintain sharpness over longer periods. This not only improves the surface finish of the machined part but also enhances the overall longevity of the tooling, ensuring consistent performance in high-volume production settings.

In addition to improved tooling materials, the integration of advanced programming techniques and software also significantly contributes to enhanced accuracy. CNC machines, equipped with sophisticated algorithms, can optimize tool paths and eliminate unnecessary movements, maximizing material removal rates while minimizing cycle times. Furthermore, the implementation of real-time monitoring systems allows for immediate adjustments based on feedback from the machining process, ensuring that any deviations from desired specifications are promptly corrected. Together, these advancements in tooling and programming serve to elevate the standards of precision in CNC machining, leading to higher quality output and increased operational efficiency.

Implementing Quality Control Measures in CNC Machining for Optimal Results

Quality control is a cornerstone of precision CNC machining, ensuring that every component produced meets stringent specifications and tolerances. Implementing effective quality control measures can significantly enhance both efficiency and accuracy in the manufacturing process. This begins with defining clear standards and employing advanced measuring tools throughout the machining cycle. Regular inspections during production can identify deviations early, minimizing waste and preventing costly rework. Techniques such as statistical process control (SPC) can also be used to monitor processes in real-time, allowing for immediate adjustments to be made before defects occur.

In addition to proactive inspections, fostering a culture of quality among the workforce is crucial. Training operators on the importance of adhering to quality standards and utilizing tools such as calipers and coordinate measuring machines (CMM) can empower them to take ownership of the production quality. Implementing feedback loops where operators and quality control personnel collaborate can lead to continuous improvement in processes. A robust quality management system that integrates these practices can help ensure that every part produced not only meets client specifications but also contributes to the overall efficiency and reputation of the machining operation.

Future Trends in CNC Machining Techniques for Improved Performance

As the field of CNC machining continues to evolve, future trends are pointing towards enhanced automation and integration of advanced technologies. One significant trend is the incorporation of artificial intelligence and machine learning algorithms. These technologies enable CNC machines to adapt in real time, optimizing their operations based on data collected during the machining process. By analyzing patterns and predicting tool wear or maintenance needs, AI-driven systems can drastically reduce downtime and increase overall productivity.

Another emerging trend is the shift towards sustainable machining practices. With growing environmental concerns, manufacturers are exploring alternative materials and energy-efficient CNC machining methods. Innovations such as biodegradable cutting fluids and eco-friendly materials not only help in minimizing the carbon footprint but also promote a circular economy within the manufacturing sector. Moreover, advancements in additive manufacturing are being integrated with traditional CNC processes, allowing for more complex geometries and reduced waste, further enhancing performance and efficiency in precision machining.

Top 10 Precision CNC Machining Techniques for Maximum Efficiency and Accuracy

Related Posts

-

Unleashing China's Premier CNC Machining for Global Market Leadership

-

7 Secrets to Finding the Best CNC Precision Machining Suppliers Worldwide

-

Understanding Global Industry Standards for Best CNC Machining Precision Production

-

Exploring the Future of Best High Speed CNC Machining Innovations for 2025

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Discover How Best Precision Machining from China Leads Global Manufacturing Excellence