- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

How to Optimize Your Workflow with a 5 Axis Milling Machine

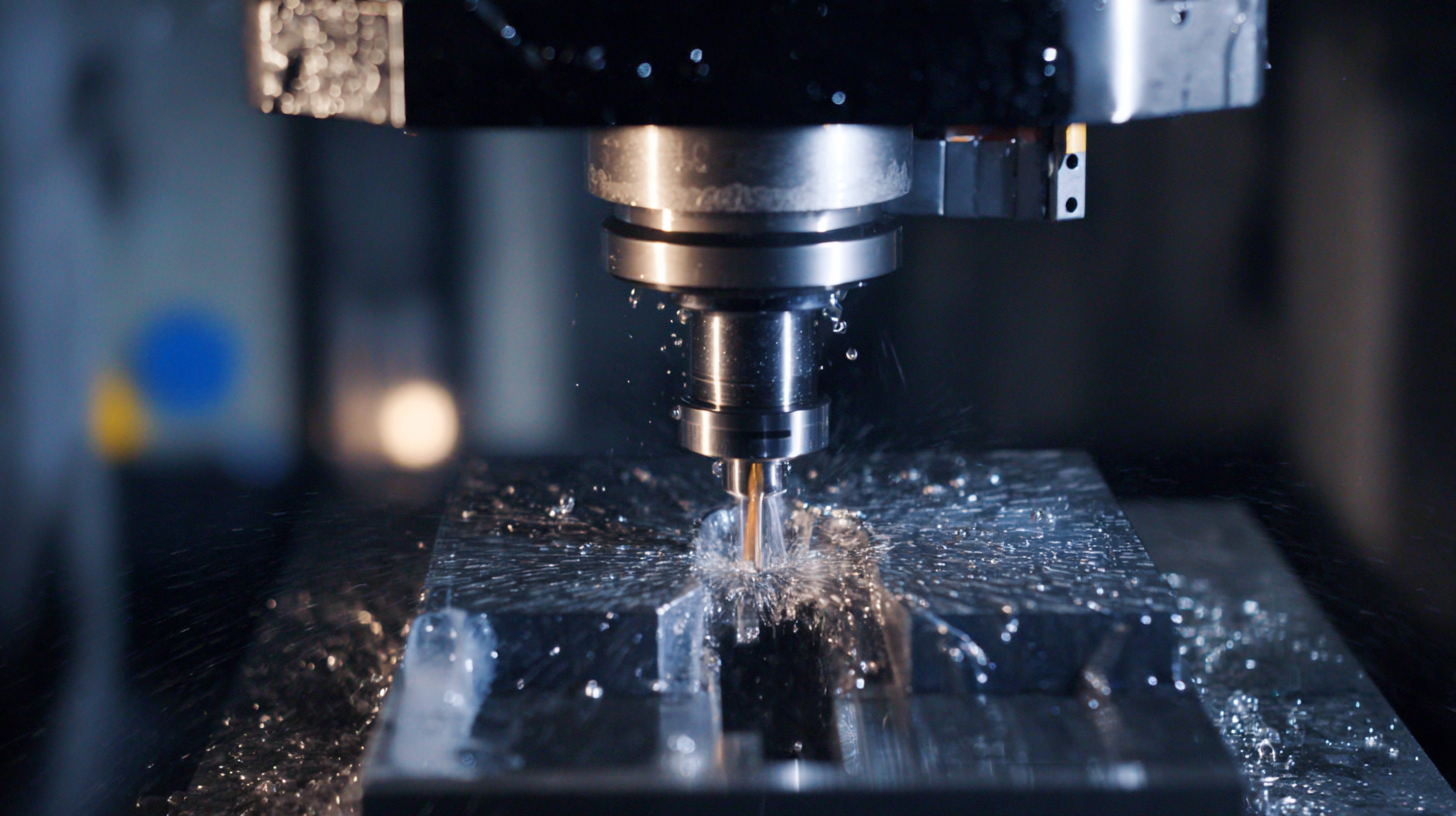

In today's competitive manufacturing landscape, optimizing workflows has become crucial for achieving efficiency and cost-effectiveness. The integration of advanced technologies, such as the 5 axis milling machine, is a game-changer in streamlining production processes. According to a report by Research and Markets, the global CNC machine market is projected to reach $100 billion by 2025, with a significant portion attributed to advancements in multi-axis machining. The 5 axis milling machine, known for its precision and versatility, enables manufacturers to produce complex geometries with fewer setups and reduced lead times. By leveraging the capabilities of these machines, businesses can enhance their productivity and maintain a competitive edge, responding swiftly to market demands while delivering high-quality products. This article explores effective strategies for optimizing workflows with 5 axis milling machines, ensuring that manufacturers can harness their full potential.

Understanding the Basics of 5 Axis Milling Machines for Workflow Optimization

5-axis milling machines are revolutionizing the manufacturing landscape by significantly enhancing workflow efficiency. These advanced machines enable simultaneous movement along five axes, allowing for intricate designs and complex geometries that were once challenging or impossible to achieve with traditional machining methods. According to recent industry reports, implementing 5-axis milling can reduce cycle times by approximately 30%, showcasing its effectiveness in optimizing production processes.

Understanding the intricacies of post processors is crucial for getting the most out of your 5-axis milling machine. A post processor converts the CAM program into the specific G-code that your machine understands, making it an essential component in your workflow. By properly configuring your post processors in Fusion, you can fine-tune the machining process, ensuring precision and efficiency.

**Tips:** When configuring post processors, always verify compatibility with your CNC machine to mitigate errors. Additionally, regularly updating your software can enhance functionality and streamline your operations. Finally, don't hesitate to experiment with different cutting strategies; minor adjustments can lead to significant improvements in machining performance.

Key Advantages of 5 Axis Milling Over Traditional Machining Techniques

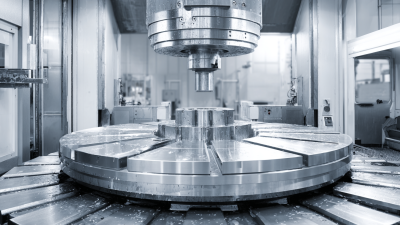

5 Axis milling machines have revolutionized the manufacturing landscape by introducing a level of precision and efficiency that traditional machining techniques cannot match. One of the key advantages of 5 Axis milling is its ability to produce complex geometries in a single setup, minimizing the need for multiple tool changes and setups. This drastically reduces the time spent on job preparation and part handling, allowing manufacturers to increase their production rates without compromising quality.

Another significant benefit is the enhanced flexibility that 5 Axis machines provide. Unlike traditional 3 Axis mills, which are limited to movement along the X, Y, and Z axes, 5 Axis machines can manipulate the workpiece from various angles. This capability allows for better access to intricate parts and contours, making it ideal for industries like aerospace and medical device manufacturing where precision is paramount. The result is a decrease in the likelihood of human error and improved surface finish quality, ultimately leading to a lower cost per part in high-volume production scenarios.

How to Optimize Your Workflow with a 5 Axis Milling Machine

| Advantage | Description | Impact on Workflow |

|---|---|---|

| Increased Efficiency | Ability to perform multiple operations in a single setup. | Reduces setup time significantly. |

| Complex Geometry | Capable of creating intricate shapes that are difficult to achieve with traditional methods. | Enables design flexibility and innovation. |

| Improved Surface Finish | Enhanced tool path control leads to superior finish quality. | Reduces the need for extensive post-processing. |

| Reduced Human Error | Automated processes minimize chances of operator mistakes. | Improves overall quality and consistency. |

| Versatile Applications | Suitable for various industries including aerospace, automotive, and medical. | Increases market opportunities and adaptability. |

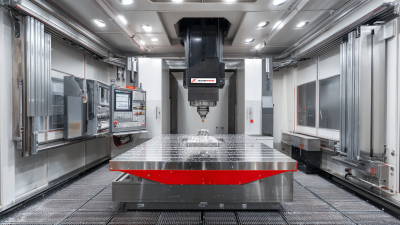

Setting Up Your 5 Axis Milling Machine for Maximum Efficiency

To achieve maximum efficiency with a 5-axis milling machine, proper setup is critical. Begin by ensuring that the machine is located in an optimal environment, minimizing vibrations and ensuring temperature stability. The workspace should be well-organized, with tools and materials easily accessible. Once the machine is in place, calibrate its geometric accuracy. This involves aligning the axes and ensuring that the tool paths are precisely defined, as small errors can lead to significant discrepancies in the final product.

Tool selection and management play an essential role in the setup process. Use high-quality tools that are appropriate for the materials you will be machining. Additionally, implementing a tool management system can help track tool wear and replacements, ensuring consistency in production. Adjust the machine parameters according to the specific requirements of the task at hand, such as feed rates and spindle speeds. Regularly review and refine these settings based on operational feedback to enhance overall efficiency and prolong the machine's lifespan.

Optimizing Workflow Efficiencies using 5 Axis Milling Machines

Essential Software Tools for Streamlining 5 Axis Workflow

When optimizing your workflow with a 5 axis milling machine, leveraging the right software tools is essential. One of the most significant advancements in recent years is the introduction of AI-powered features in various design software. These tools can automate the creation of 2D drawings from 3D models, thereby significantly reducing the amount of manual input required. This not only speeds up the design phase but also minimizes errors that typically arise during traditional drawing processes.

Incorporating these advanced software solutions into your 5 axis milling operations can drastically enhance productivity and accuracy. By streamlining the workflow, operators can focus more on the machining process itself rather than spending excessive time on drafting and revisions. Moreover, with the ability to quickly generate precise drawings, businesses can improve their turnaround times and ultimately increase their competitiveness in the manufacturing sector. Embracing innovative software tools is a key strategy for achieving efficiency and excellence in 5 axis milling.

Tips for Effective Tool Management and Maintenance in 5 Axis Machining

Effective tool management and maintenance are crucial for optimizing workflows in 5-axis machining environments. Implementing a systematic approach to tool organization can significantly enhance efficiency and reduce downtime. This involves routine checks to identify wear and tear on tools, employing advanced data management strategies to predict tool life, and ensuring timely replacements. Utilizing cutting-edge predictive maintenance techniques can further streamline operations by analyzing sensor data to monitor the condition of tools and machinery in real-time, enabling early detection of potential issues before they escalate.

Effective tool management and maintenance are crucial for optimizing workflows in 5-axis machining environments. Implementing a systematic approach to tool organization can significantly enhance efficiency and reduce downtime. This involves routine checks to identify wear and tear on tools, employing advanced data management strategies to predict tool life, and ensuring timely replacements. Utilizing cutting-edge predictive maintenance techniques can further streamline operations by analyzing sensor data to monitor the condition of tools and machinery in real-time, enabling early detection of potential issues before they escalate.

Moreover, understanding the specific requirements for machining complex materials, such as nickel-based alloys, is essential. Selecting the appropriate tooling, based on the characteristics of the alloy and planned machining strategies, can improve both speed and accuracy. Additionally, establishing a robust training program for operators on tool handling and maintenance best practices can lead to enhanced productivity and reduced error rates. By investing time in both tool management and operator education, businesses can fully leverage the capabilities of their 5-axis milling machines, ensuring seamless integration into their manufacturing processes.

Related Posts

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

-

Understanding Industry Production Standards for Optimal High Speed Machining Performance

-

Ultimate Checklist for Selecting the Best 5 Axis Machining Services

-

The Ultimate Guide to High Precision Machining for Global Buyers in 2023

-

7 Key Benefits of CNC Machines That Can Revolutionize Your Manufacturing Process