- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

What is a Milling Machine and How Does it Work in Manufacturing Process

Milling machines play a crucial role in the manufacturing process, serving as essential tools for shaping and cutting materials with precision. These versatile machines are designed to remove material from a workpiece by feeding it against a rotating cutting tool, which allows for the creation of complex shapes and intricate designs. Understanding how milling machines operate gives insight into their significance in various industries, from automotive to aerospace and beyond.

In essence, milling machines have evolved significantly over the years, incorporating advanced technologies that enhance their efficiency and effectiveness. They can perform a range of operations, including drilling, boring, and contouring, thereby offering manufacturers the flexibility needed to meet diverse production demands. By effectively transforming raw materials into finished products, milling machines contribute to streamlining the manufacturing process and boosting productivity.

As we delve deeper into the workings of milling machines, it becomes apparent that their design and versatility are key factors that make them indispensable in modern manufacturing. By exploring their mechanisms, types, and applications, we can gain a comprehensive understanding of how milling machines continue to innovate and shape the future of production.

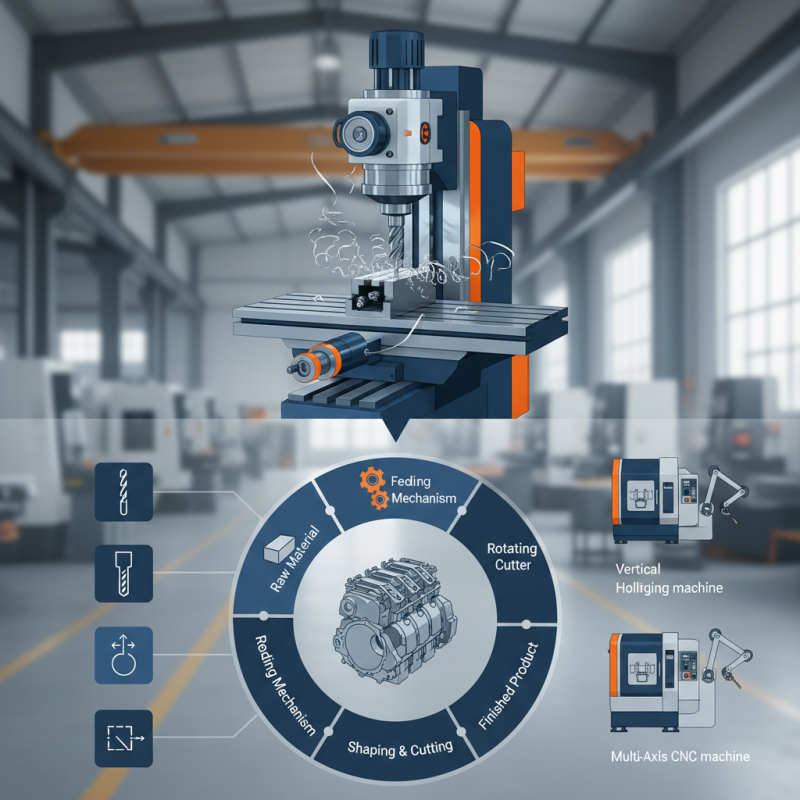

What is a Milling Machine? An Overview of Its Definition and Types

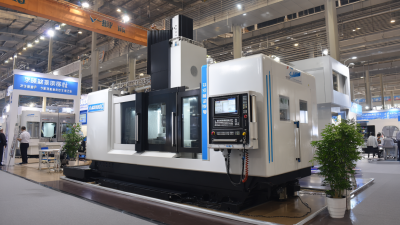

Milling machines are essential tools in modern manufacturing, widely used for shaping and machining various materials. A milling machine functions by using rotary cutters to remove material from a workpiece, allowing for precise shaping and finishing. In the industry, there are several types of milling machines, including vertical, horizontal, and CNC (computer numerical control) milling machines. Each type offers distinct advantages, suited for specific manufacturing needs. According to a recent report by Markets and Markets, the global milling machine market is projected to grow at a compound annual growth rate (CAGR) of over 5% from 2021 to 2026, driven by advancements in technology and increasing automation in manufacturing processes.

When choosing the right milling machine, it's important to consider the type of projects you'll be undertaking. For instance, CNC milling machines are perfect for high-precision tasks, allowing for intricate designs to be executed seamlessly. Tips for maximizing efficiency include regularly maintaining your milling equipment and familiarizing yourself with the specific functions and capabilities of your chosen machine. Understanding the operational limits and advantages of each machine type can significantly enhance productivity and reduce downtime.

Additionally, the versatility of milling machines allows manufacturers to work with a variety of materials, including metal, plastic, and wood. The ability to create complex shapes and designs makes milling machines not just a staple in metalworking shops but also in woodworking and plastic engineering. In fact, studies indicate that the milling process can reduce production times by as much as 30% compared to traditional machining methods, emphasizing the importance of integrating modern milling solutions in today’s competitive manufacturing landscape.

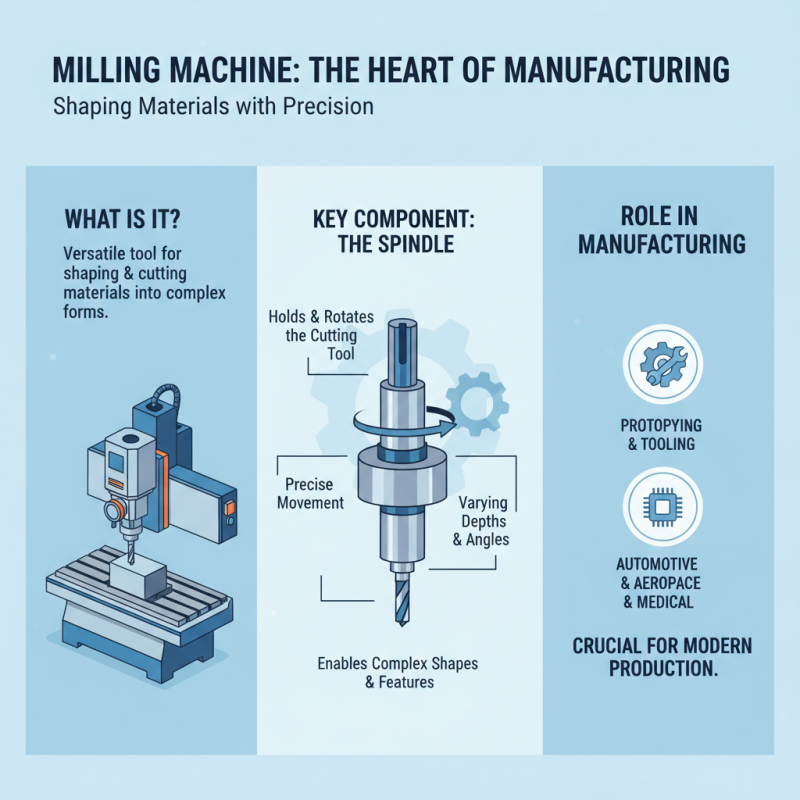

The Basic Components of a Milling Machine and Their Functions

Milling machines are vital tools in the manufacturing sector, utilized for shaping and cutting materials into desired forms. The basic components of a milling machine play crucial roles in its operation. The most significant of these components is the spindle, which holds and rotates the cutting tools. It is through the spindle's precise movement that the milling process can achieve various depths and angles of cut, allowing for complex shapes and features to be carved out of raw materials.

Another essential part of the milling machine is the table, which supports the workpiece during machining. The table can move vertically and horizontally, ensuring that the workpiece is positioned accurately relative to the cutting tool. This adjustability is key for achieving precise dimensions and surface finishes. Additionally, the machine's feed mechanism allows for controlled movement of the workpiece or the tool, further enhancing the milling process's efficiency and accuracy. Together, these components facilitate a wide range of milling operations, making the machine indispensable in modern manufacturing.

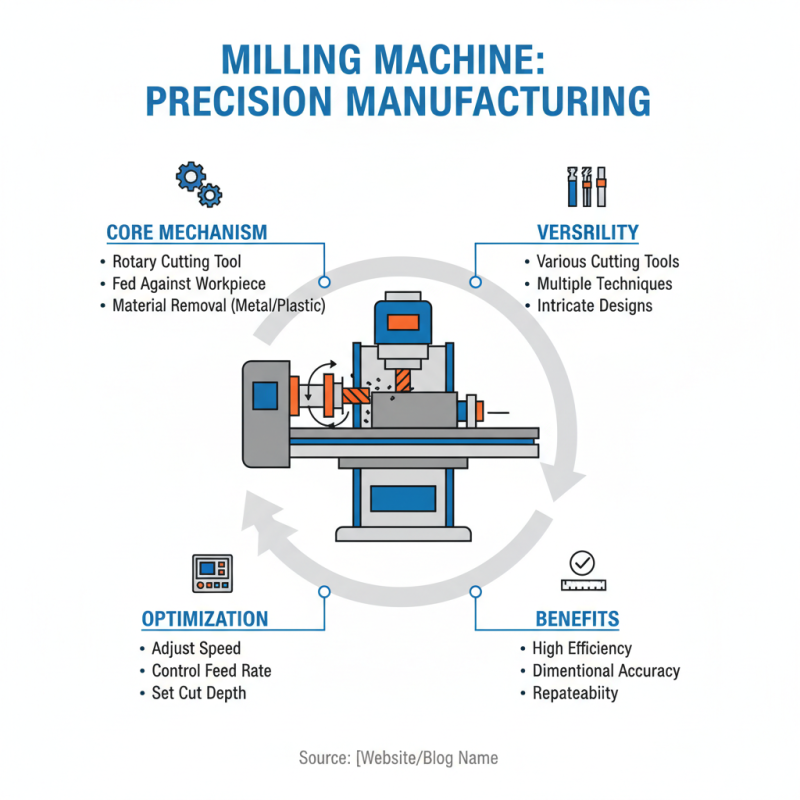

How Milling Machines Operate: Key Processes and Mechanisms Explained

Milling machines are essential tools in the manufacturing process, operating through a precise mechanism that allows for the shaping and altering of materials, typically metals or plastics. The core function of a milling machine revolves around the rotary motion of a cutting tool, which is then fed against the workpiece. This process can be highly versatile, accommodating various cutting tools and techniques to achieve intricate designs and specifications. By adjusting the speed, feed rate, and depth of cut, operators can optimize the milling process for different applications, ensuring high efficiency and accuracy.

The key processes involved in milling include peripheral milling, where the cutting tool rotates on an axis parallel to the workpiece, and face milling, where the tool's axis is perpendicular to the workpiece. These processes allow for the removal of material in different orientations, enabling the creation of complex geometries. Furthermore, milling machines can operate in both horizontal and vertical configurations, expanding their capacity to tackle various tasks. The integration of CNC (Computer Numerical Control) technology has further enhanced the precision and repeatability of milling operations, allowing for automated processes that significantly reduce human error and improve productivity in modern manufacturing environments.

Applications of Milling Machines in Manufacturing: Industries and Examples

Milling machines play a pivotal role in various manufacturing sectors, thanks to their versatility and precision. These machines are widely used in industries such as automotive, aerospace, and electronics to create intricate parts with high accuracy. For example, in the automotive industry, milling machines are used to produce components like engine blocks and transmission cases. The ability to manipulate various materials, from metals to plastics, allows manufacturers to customize parts for specific applications, enhancing the overall product quality and performance.

In the aerospace sector, milling machines are essential for fabricating lightweight yet durable components. Precision is crucial in this field, as even the smallest deviation can affect the safety and efficiency of aircraft. Moreover, the electronics industry utilizes milling machines to create circuit boards and casings, showcasing the machine's ability to work with delicate materials while ensuring precision in intricate designs.

Tips: When selecting a milling machine for your operations, consider factors like the size and type of materials you will be processing, the complexity of the parts, and the desired precision levels. Regular maintenance is also crucial to ensure optimal performance and longevity of the machine. Always stay updated with advancements in milling technology to improve efficiency and reduce production costs.

Applications of Milling Machines in Various Industries

Current Trends in Milling Technology: Automation and Efficiency Improvements

Current trends in milling technology are increasingly leaning towards automation and efficiency improvements, reflecting the industry's pursuit of enhanced production capabilities. Automating milling processes not only reduces the need for manual intervention but also minimizes the chances of human error, leading to more consistent and reliable outputs. Advanced control systems and robotics are being integrated into milling operations, facilitating real-time adjustments and optimizing cutting parameters based on material properties and desired geometries. This integration of technology allows manufacturers to increase their production rates while maintaining high-quality standards.

Moreover, the emphasis on efficiency has driven the development of smart milling machines equipped with IoT (Internet of Things) capabilities. These machines can monitor operational data and predict maintenance needs, resulting in less downtime and improved overall productivity. By adopting energy-efficient practices and materials, manufacturers are also working to reduce waste during the milling process. These innovations not only enhance operational performance but also contribute to sustainability efforts within the manufacturing sector, positioning businesses to meet both their economic goals and environmental responsibilities.

What is a Milling Machine and How Does it Work in Manufacturing Process - Current Trends in Milling Technology: Automation and Efficiency Improvements

| Aspect | Description | Current Trend |

|---|---|---|

| Milling Machine Types | Vertical, Horizontal, CNC | Increased Use of CNC Milling |

| Main Components | Table, Spindle, Tool Holder | Integration of Smart Sensors |

| Automation Level | Manual, Semi-Automatic, Fully Automatic | Shift Towards Fully Automated Systems |

| Efficiency Metrics | Cutting Speed, Feed Rate, Tool Life | Focus on Reducing Cycle Times |

| Materials Used | Metals, Plastics, Composites | Adoption of Advanced Materials |

| Sustainability | Energy Consumption, Waste Management | Implementing Green Manufacturing Practices |

Related Posts

-

How to Choose the Right Milling Machine for Your Business Needs

-

7 Key Benefits of CNC Machines That Can Revolutionize Your Manufacturing Process

-

Exploring Innovations in Vertical Machining Centers at the 138th Canton Fair 2025: A Data-Driven Perspective

-

Top 5 Benefits of High Precision Machining for Modern Manufacturing

-

5 Reasons the Best High Speed CNC Machines Boost Production Efficiency by 30%

-

Top Strategies for Sourcing the Best High Precision Machining Solutions Worldwide