- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

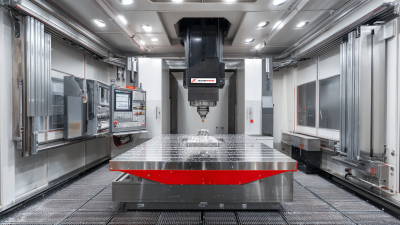

In the rapidly evolving landscape of manufacturing, the adoption of 3 axis CNC machines has become critical for enhancing operational efficiency and precision. According to a recent report by MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, driven by the increasing demand for automated manufacturing processes. As industries strive for faster production turnaround and reduced costs, leveraging the capabilities of 3 axis CNC technology can lead to significant improvements in workflow and productivity.

This blog will explore the five best strategies to maximize efficiency with 3 axis CNC machines, providing insights into optimizing machine performance, reducing cycle times, and ensuring consistent quality in production. Embracing these strategies is not just an option but a necessity for businesses aiming to stay competitive in today's market.

Best Practices for Tool Selection to Enhance CNC Efficiency

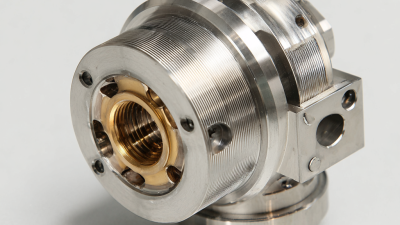

When it comes to maximizing efficiency with 3-axis CNC machines, selecting the right tools is critical. The choice of tooling can significantly affect machining speed, accuracy, and overall productivity. To enhance CNC efficiency, manufacturers should prioritize using high-quality cutting tools that are specifically designed for the materials being machined. For instance, carbide tools offer durability and better performance with harder materials, while high-speed steel may be more appropriate for softer substrates.

Another key aspect of tool selection is sizing and spacing. Choosing the correct diameter and length for the tool can influence the rigidity and stability of the machining process. Tools that are too long may introduce flex during operation, leading to inaccuracies. Therefore, it’s advisable to match the tool dimensions closely to the requirements of the part being machined. Furthermore, using specialized tools, such as end mills with varying flute numbers can cater to specific machining tasks, providing versatility and improving overall cycle times. This strategic approach in tool selection not only boosts efficiency but also contributes to a higher quality end product.

Understanding Feed Rates: Balancing Speed and Material Integrity

When working with 3-axis CNC machines, understanding feed rates is essential to achieving optimal efficiency while preserving material integrity. Feed rate refers to the speed at which the tool moves through the material, impacting both machining time and the quality of the finished product. Balancing speed and the integrity of the material is crucial; too fast a feed can lead to tool wear and poor surface finish, while too slow can result in excessive machining time and higher operational costs.

To achieve an ideal feed rate, consider adjusting the speed based on the material type. Softer materials can often handle higher feed rates, while harder materials may require slower speeds to avoid damaging the tool or workpiece. Additionally, monitor the machine's response during cutting; listen for any unusual sounds that may indicate incorrect feed settings.

Another effective tip is to run test cuts before committing to larger production runs. This will allow you to refine your feed rates based on real-time observations and results. By doing so, you can determine the best balance between speed and quality, ultimately maximizing your CNC machine's efficiency.

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

Understanding Feed Rates: Balancing Speed and Material Integrity

Optimizing Workpiece Setup: Strategies for Increased Precision

When working with 3 axis CNC machines, optimizing workpiece setup is crucial for achieving increased precision and efficiency. One effective strategy is to thoroughly plan the workpiece placement before starting the machining process. This includes measuring the dimensions of the workpiece accurately and ensuring that it is securely clamped to prevent any movement during operation.

Investing time in this initial setup can significantly reduce the potential for errors, which can lead to wasted materials and costly rework.

Another key aspect of optimizing workpiece setup lies in utilizing specialized fixtures and jigs designed for specific projects.

These tools not only enhance the stability of the workpiece but also promote better alignment with the CNC machine. Additionally, implementing a repeatable setup process can help streamline production, allowing for quicker changeovers between jobs.

By standardizing these procedures, operators can ensure consistent results and maintain high levels of precision, ultimately maximizing the benefits of their CNC machinery.

Leveraging CNC Software: Advanced Techniques for Workflow Automation

The integration of advanced CNC software represents a game-changing approach to optimizing the workflow of 3-axis CNC machines. By leveraging powerful software tools, manufacturers can automate complex processes, significantly reducing the time required for programming and setup. For example, using advanced CAD/CAM software not only streamlines the design process but also automatically generates toolpaths, minimizing errors and maximizing machine uptime. This automation allows operators to focus on overseeing production rather than getting bogged down in manual programming tasks.

Another effective strategy is the real-time monitoring and analytics offered by modern CNC software. These tools can provide valuable insights into machine performance and efficiency, enabling operators to identify bottlenecks and implement corrective measures swiftly. By analyzing data trends, manufacturers can refine their workflows, schedule maintenance proactively, and ultimately enhance production quality. The synergy between advanced CNC software and 3-axis machines not only boosts efficiency but also fosters an environment of continuous improvement, vital for staying competitive in today’s fast-paced manufacturing landscape.

Regular Maintenance Routines: Ensuring Longevity and Consistency in Performance

Regular maintenance routines are crucial for maximizing the efficiency of 3 Axis CNC machines. According to a report by the National Center for Advanced Manufacturing, regular upkeep can increase machine longevity by up to 30%. Furthermore, machines that undergo consistent maintenance display a 25% reduction in breakdowns, directly impacting production schedules and operational costs. Ensuring that all components, from spindle bearings to linear rails, are inspected and serviced can help maintain precise tolerances, which is vital for high-quality output.

Additionally, incorporating predictive maintenance through data analysis can take routine checks a step further. A study by McKinsey & Company found that companies implementing predictive analytics in their maintenance procedures experienced a 10-20% reduction in maintenance costs while simultaneously enhancing equipment reliability. By utilizing sensors and monitoring software, manufacturers can identify potential issues before they lead to significant downtime. Thus, establishing a regular maintenance schedule not only guarantees the longevity and performance consistency of CNC machines but also optimizes overall manufacturing efficiency.

Related Posts

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

5 Reasons High Speed CNC Machining Can Boost Your Production Efficiency by 50 Percent

-

7 Key Benefits of CNC Machines That Can Revolutionize Your Manufacturing Process

-

Understanding Global Industry Standards for Best CNC Machining Precision Production

-

Unleashing China's Premier CNC Machining for Global Market Leadership

-

Exploring the Future of Best High Speed CNC Machining Innovations for 2025