- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

7 Key Benefits of CNC Machines That Can Revolutionize Your Manufacturing Process

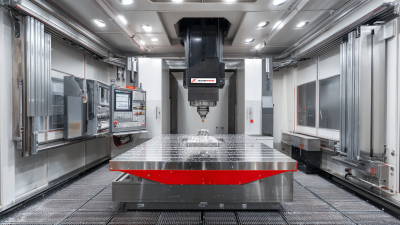

In today’s fast-paced manufacturing landscape, the adoption of CNC machines has become a game changer for businesses striving to optimize their production processes. CNC, or Computer Numerical Control machines, empower manufacturers with precision, efficiency, and versatility, transforming traditional workflows into highly automated operations. This blog delves into the seven key benefits of CNC machines that can revolutionize your manufacturing process, highlighting how these sophisticated tools not only enhance accuracy but also reduce lead times and waste. As industries continue to evolve, embracing CNC technology is no longer optional but essential for staying competitive and meeting the demands of modern consumers.

Join us as we explore the transformative potential of CNC machines and discover why they are integral to the future of manufacturing.

Advantages of Precision: How CNC Machines Enhance Product Quality

CNC machines have transformed the manufacturing landscape, particularly in enhancing product quality through precision engineering. Unlike conventional methods, precision machining capabilities allow for submicron accuracy, which is particularly crucial in sectors like medical device fabrication. This level of precision not only ensures compliance with stringent regulatory standards but also significantly reduces the likelihood of defects, thus improving overall product integrity.

Recent market analyses indicate a strong growth trajectory in the precision engineering machine sector, with the market size projected to reach USD 28.54 billion by 2034. This surge emphasizes the increasing demand for precision tools that can deliver exceptional performance while adhering to high-quality standards. Furthermore, the integration of advanced technologies such as digital twins in CNC operations reinforces the importance of precision. These digital counterparts facilitate real-time monitoring, reducing the risk of collisions and ensuring a seamless alignment between virtual models and physical machinery, thereby enhancing the quality of the final products.

Boosting Efficiency: The Role of CNC in Accelerating Manufacturing Cycles

CNC machines are pivotal in boosting efficiency within the manufacturing sector, significantly accelerating production cycles. The rise of automation has transformed traditional manufacturing processes, allowing for higher precision and decreased cycle times. A recent study published in the Journal of Industrial Engineering and Management Studies highlights that reducing cycle times is key to productivity improvements, enabling manufacturers to respond swiftly to market demands. With CNC technology, manufacturers can achieve the high-speed operation and accuracy required to meet these challenges effectively.

Moreover, the global market for precision engineering machines is projected to reach approximately USD 29.16 billion by 2034, up from USD 19.27 billion, underscoring the growing reliance on CNC technology in various manufacturing applications. This shift not only contributes to operational efficiency but also reflects the increasing adoption of advanced technologies in the manufacturing ecosystem. As organizations incorporate AI and 3D printing alongside CNC machining, they are positioning themselves to innovate and enhance their output, showcasing the critical role of CNC in modern manufacturing strategies.

Cost-Effectiveness: Reducing Waste and Optimizing Resources with CNC

CNC machines have significantly transformed the landscape of manufacturing, particularly when it comes to cost-effectiveness. By automating processes, these machines minimize human error, leading to reduced waste and more precise production. This precision ensures that materials are utilized efficiently, cutting down on excess and saving both time and money. For manufacturers looking to optimize their resources, investing in CNC technology is not just an upgrade; it's a strategic move towards sustainable production.

Tip: To maximize the cost-effectiveness of CNC machines, consider regular maintenance. Keeping your equipment in optimal condition prevents costly breakdowns and extends its lifecycle, allowing you to get the most out of your investment.

Moreover, CNC machines allow for the creation of complex designs that would be labor-intensive and costly with conventional methods. The flexibility of CNC manufacturing enables companies to switch between designs quickly, adapting to market demands without significant downtime. This agility not only helps in reducing costs but also enhances productivity.

Tip: Implementing a just-in-time (JIT) inventory system can further enhance the cost-effectiveness of using CNC machines by reducing holding costs and allowing for a more responsive production approach.

Versatility and Flexibility: Adapting CNC Technology to Diverse Projects

CNC (Computer Numerical Control) technology has transformed the landscape of manufacturing, offering unparalleled versatility and flexibility to meet a wide range of project requirements. One of the significant advantages of CNC machines is their ability to produce complex shapes and designs with precision. This capability is invaluable in industries such as aerospace, automotive, and custom fabrication, where specific part geometry is crucial. By utilizing CAD (Computer-Aided Design) software, manufacturers can easily adapt designs for small batches or mass production, enabling a seamless transition for projects of differing scales.

Moreover, the adaptability of CNC machines extends beyond just design complexity. They can work with various materials such as metals, plastics, and wood, allowing manufacturers to switch between projects without extensive modifications to their setup. This flexibility not only reduces downtime but also enhances the overall efficiency of the manufacturing process. As businesses aim to cater to ever-changing market demands, the ability to pivot quickly and manipulate resources effectively becomes essential for growth and competitiveness. Embracing CNC technology can lead manufacturers toward innovative solutions, pushing the boundaries of what’s possible in production.

7 Key Benefits of CNC Machines That Can Revolutionize Your Manufacturing Process

This bar chart illustrates the key benefits of CNC machines in manufacturing. Each bar represents a specific advantage that highlights the versatility and flexibility of CNC technology in adapting to diverse projects.

Enhanced Safety Features: Protecting Workers and Equipment in CNC Operations

The advancement of CNC (Computer Numerical Control) machines has significantly transformed manufacturing processes, particularly concerning safety features that protect both workers and equipment. One of the standout benefits of CNC technology is its ability to automate tasks, reducing the need for manual handling of machinery. This not only minimizes the risk of physical injuries but also ensures that dangerous tasks are handled by machines programmed to execute them with precision. As a result, operators can maintain a safe distance from hazardous operations, creating a safer work environment.

In addition to reducing human risk factors, CNC machines are equipped with advanced safety features such as emergency stop buttons, protective enclosures, and real-time monitoring systems. These systems alert operators to potential hazards before accidents occur, enabling timely interventions. For example, if a machine senses an anomaly during operation, it can automatically halt production, preventing equipment damage and safeguarding workers' health. The integration of such features not only enhances workplace safety but also contributes to the overall efficiency of manufacturing processes, allowing for a more reliable and secure production environment.

Related Posts

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Exploring the Future of Best High Speed CNC Machining Innovations for 2025

-

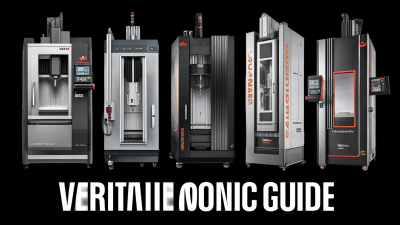

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

-

7 Secrets to Finding the Best CNC Precision Machining Suppliers Worldwide

-

5 Reasons High Speed CNC Machining Can Boost Your Production Efficiency by 50 Percent

-

Ultimate Guide to the Top Five Vertical CNC Machines Compared for Best Performance