- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

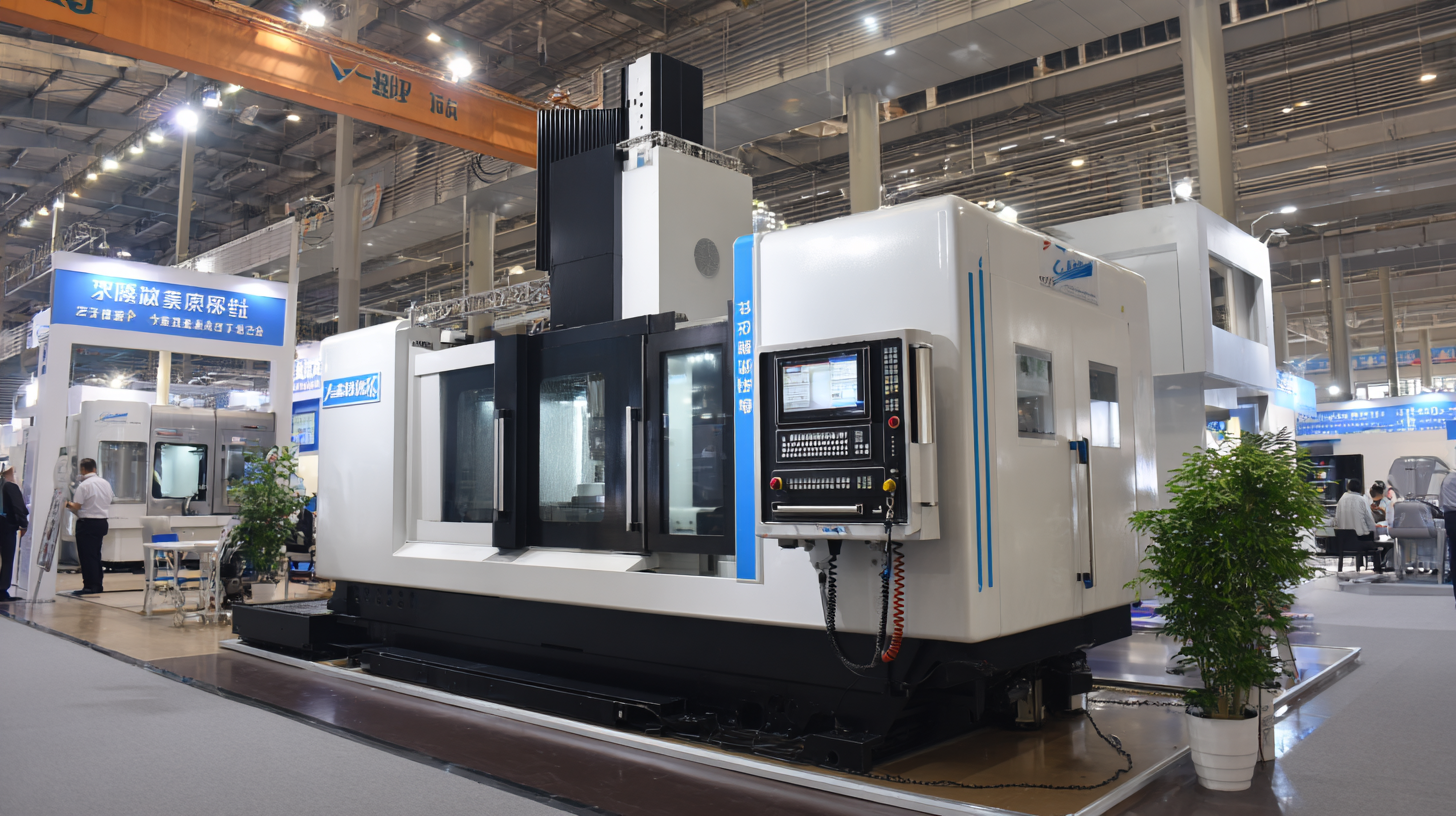

Exploring Innovations in Vertical Machining Centers at the 138th Canton Fair 2025: A Data-Driven Perspective

The 138th Canton Fair in 2025 presents a significant opportunity to explore the latest innovations in vertical machining centers, a critical segment of the manufacturing sector. According to a recent report by MarketsandMarkets, the global vertical machining center market is projected to reach $10.8 billion by 2026, growing at a CAGR of 6.5% from 2021 to 2026. This growth is driven by the increasing demand for precision engineering and automation across various industries, including automotive and aerospace. The Canton Fair serves as a pivotal platform for stakeholders to engage with cutting-edge technology, showcasing advancements that enhance efficiency, precision, and cost-effectiveness in machining processes.

As manufacturers strive to meet evolving market demands, the integration of advanced technologies such as AI and IoT in vertical machining centers will be at the forefront of discussions, positioning them as indispensable tools in modern manufacturing.

Innovative Trends in Vertical Machining Centers Showcased at Canton Fair 2025

At the 138th Canton Fair 2025, vertical machining centers (VMCs) are taking center stage, showcasing a myriad of innovative trends that are set to revolutionize manufacturing processes. One of the standout features this year is the integration of AI and IoT technologies into VMC designs. These advancements enable real-time monitoring and predictive maintenance, reducing downtime and enhancing operational efficiency. Manufacturers are embracing automation and robotics to further streamline production, allowing for higher precision and improved quality control.

Tips: When exploring new vertical machining centers, consider the operational requirements of your facility. Evaluate factors such as space, power consumption, and compatibility with existing equipment. It’s essential to engage with suppliers at the fair to gain insights into the latest advancements tailored to your needs.

Moreover, sustainable practices are becoming increasingly prominent in VMC innovations. Eco-friendly machining processes, including energy-efficient operations and reduced waste generation, are key trends that manufacturers need to adopt. These approaches not only benefit the environment but also reduce costs in the long run.

Tips: Stay informed about green technologies in machining. Participating in workshops or discussions at the fair can provide valuable knowledge on how to implement sustainability into your operations effectively.

Innovative Trends in Vertical Machining Centers Showcased at Canton Fair 2025

This bar chart represents the innovative features incorporated in Vertical Machining Centers showcased at the 138th Canton Fair 2025. The data demonstrates advancements such as automation, precision, energy efficiency, and user interface improvements.

Key Technological Advancements in Vertical Machining Center Design

At the 138th Canton Fair 2025, the latest innovations in vertical machining centers (VMCs) will take center stage, showcasing advancements that are transforming manufacturing efficiency and precision. Recent industry reports indicate that the global vertical machining center market is projected to reach $6.2 billion by 2026, growing at a CAGR of 5.6% from 2021. This growth underscores the rising demand for more sophisticated and reliable manufacturing solutions.

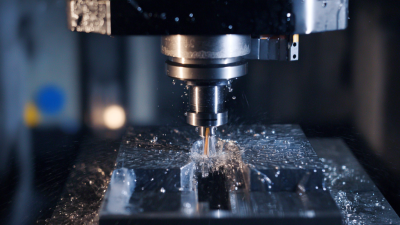

One key technological advancement to be highlighted at the fair is the integration of artificial intelligence (AI) in VMC design. AI-assisted machining can optimize cutting parameters in real time, leading to increased productivity and reduced material waste. Additionally, advancements in CNC software are enabling manufacturers to achieve greater levels of automation and data analytics, leading to smarter production processes.

Tip: For manufacturers looking to upgrade their VMCs, consider investing in models that include IoT capabilities. These machines can collect and analyze operational data to streamline processes and reduce downtime, ensuring that your manufacturing line remains competitive in a rapidly evolving market.

Another notable trend is the enhancement of machine ergonomics and user-friendly interfaces, which facilitate better operator control and safety. With the introduction of touch screen controls and easily customizable settings, operators can reduce setup times and improve overall efficiency.

Tip: When evaluating new VMCs, prioritize features that offer simplified maintenance and upkeep. Machines with modular designs often result in lower long-term operational costs and increased uptime, making them an attractive investment for modern manufacturing environments.

Impact of Data Analytics on Vertical Machining Center Performance

The integration of data analytics in the performance of vertical machining centers is a pivotal trend that is shaping the future of the CNC machine market. As projected, the global CNC machine market size is expected to grow from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a significant compound annual growth rate (CAGR) of 9.9%. This growth is largely driven by innovations that leverage data analytics to enhance machine performance, efficiency, and overall productivity.

One noteworthy innovation is the development of closed-loop systems for managing thermal conditions within spindle-bearing systems. These systems address the critical issue of thermal expansion, which can significantly impact machining accuracy and longevity. Coupled with advancements in energy efficiency identification and surface roughness prediction through cutting force signals, manufacturers can now achieve energy-efficient processes while improving the quality of machined products. Moreover, the introduction of open datasets for milling processes provides valuable insights into tool life and performance, further empowering manufacturers to optimize their operations through informed decision-making anchored in robust data analysis.

Sustainability and Efficiency: The Future of Vertical Machining Centers

As the manufacturing landscape continually evolves, the emphasis on sustainability and efficiency in vertical machining centers (VMCs) has become increasingly vital. The 2023 Global CNC Machining Market Report indicates that the demand for eco-friendly machinery is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This surge is driven by the industry's commitment to reducing carbon footprints and increasing operational efficiency, aligning with broader environmental goals.

At the 138th Canton Fair in 2025, manufacturers will likely showcase innovations that epitomize these trends. Advanced VMCs are now incorporating features such as adaptive machining capabilities and energy-efficient drives that not only enhance precision but also reduce energy consumption by up to 30%. Moreover, integrating IoT technologies allows for real-time monitoring of machine performance, further optimizing energy use and minimizing waste. Reports suggest that businesses adopting such innovations notice average productivity boosts of 15% while significantly lowering operational costs, reinforcing the importance of a data-driven approach to manufacturing efficiency.

Comparative Analysis: Global vs. Chinese Innovations in Machining Technology

The 138th Canton Fair in 2025 showcased a significant range of innovations in vertical machining centers, underscoring the ongoing global competition in machining technology. A comparative analysis reveals that while China has rapidly advanced in the sector, the global landscape is characterized by diverse technological enhancements. According to a recent report by MarketsandMarkets, the global CNC machining market is projected to reach $100.6 billion by 2026, with a CAGR of 5.0% from 2021 to 2026. This growth highlights the escalating demand for precision machining solutions worldwide, a domain where both Chinese manufacturers and their global counterparts are striving for leadership.

In contrast, Chinese innovations often focus on integrating AI and IoT capabilities into machining processes. A report by the China Machinery Industry Federation indicates that Chinese manufacturers are investing heavily in smart manufacturing technologies, which are expected to penetrate the market significantly by 2025. For instance, the introduction of servomechanisms and enhanced automation in machining centers has improved operational efficiency by as much as 30%, making Chinese products increasingly competitive. As the industry evolves, understanding these comparative dynamics will be crucial for stakeholders looking to navigate the complexities of the machining technology landscape.

Exploring Innovations in Vertical Machining Centers at the 138th Canton Fair 2025: A Data-Driven Perspective

| Dimension | Global Innovations (Average) | Chinese Innovations (Average) |

|---|---|---|

| Market Growth Rate (2020-2025) | 5.2% | 7.8% |

| Investment in R&D (2022) | $2.3 billion | $1.5 billion |

| Adoption of AI in Machining | 25% | 40% |

| Annual Production Capacity (Units) | 1,000 units | 1,500 units |

| Sustainability Innovations (%) | 30% | 50% |

Related Posts

-

Understanding Industry Production Standards for Optimal High Speed Machining Performance

-

Top Strategies for Sourcing the Best High Precision Machining Solutions Worldwide

-

The Ultimate Guide to High Precision Machining for Global Buyers in 2023

-

How to Choose the Right Milling Machine for Your Business Needs

-

How to Choose the Right Machining Center for Your Manufacturing Needs

-

How to Optimize Your Workflow with a 5 Axis Milling Machine