- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Exploring the Impact of CNC Milling on Modern Manufacturing Techniques

The evolution of modern manufacturing techniques has been significantly influenced by advancements in technology, with CNC milling standing out as a pivotal innovation. As an automated process that employs computer numerical control to manage machine tools, CNC milling has transformed the landscape of manufacturing by enhancing precision, efficiency, and production scalability. This technology allows for the intricate shaping of materials, thus enabling manufacturers to produce complex components with remarkable accuracy. The versatility of CNC milling applications spans across various industries, including aerospace, automotive, and medical sectors, thereby prompting a reevaluation of traditional manufacturing practices. This exploration into the impact of CNC milling not only highlights its operational advantages but also examines the broader implications for modern production methodologies, offering insights into how this technology continues to redefine the potential of manufacturing in the 21st century.

Why CNC Milling Revolutionizes Precision Engineering in Modern Production

CNC milling has become a cornerstone of precision engineering, significantly transforming modern production methods. This technology enables manufacturers to achieve unparalleled accuracy, allowing for the creation of complex geometric shapes with tight tolerances that were previously unattainable. By automating the milling process, CNC machines eliminate human error, leading to enhanced product consistency and reliability. This revolution in production not only improves efficiency but also reduces waste, contributing to a more sustainable manufacturing landscape.

**Tips for Implementing CNC Milling Effectively:**

1. Ensure proper material selection tailored to the requirements of the final product, as different materials may behave uniquely during milling.

2. Regular maintenance of CNC machines is crucial to sustain performance levels and minimize downtime that can hinder production schedules.

3. Invest in training for operators to fully leverage the capabilities of CNC milling technology and to troubleshoot common issues that may arise during the process.

The impact of CNC milling on precision engineering cannot be overstated. Its ability to provide intricate designs and remarkable precision positions it as a vital asset in modern manufacturing, driving innovation and efficiency across various industries.

Why the Efficiency Gains from CNC Milling are Transforming Manufacturing Operations

Computer Numerical Control (CNC) milling has revolutionized modern manufacturing operations by significantly enhancing efficiency and precision in production processes. According to a report by the Global Industry Analysts, the global CNC machine market is projected to reach $118 billion by 2027, driven largely by the rising demand for automated and precise manufacturing technologies. CNC milling, in particular, plays a crucial role in this growth by reducing production times and minimizing human error, leading to higher quality outputs.

Additionally, a study published in the Journal of Manufacturing Science and Engineering highlighted that CNC milling can improve operational efficiency by as much as 30-40%. This efficiency is achieved through faster cycle times and the ability to produce complex geometries that traditional machining methods cannot achieve. The adoption of CNC milling also streamlines workflows, enabling manufacturers to respond more swiftly to market demands, which is crucial in today's fast-paced economic environment. With these tangible benefits, it’s clear that the efficiency gains from CNC milling are not just enhancements; they are transforming the landscape of manufacturing operations for the better.

Why CNC Milling Technology Enhances Design Flexibility for Manufacturers

CNC milling technology is revolutionizing modern manufacturing by enhancing design flexibility, which is essential in today’s fast-paced market. According to a report by Grand View Research, the CNC machining market is expected to reach $100 billion by 2025, reflecting the growing adoption of this technology across various sectors. One of the key advantages of CNC milling is its ability to create complex geometries with unparalleled precision. Manufacturers can now produce intricate designs that were previously prohibitive due to the limitations of traditional machining methods.

Moreover, CNC milling allows for rapid prototyping and iterative design processes, enabling manufacturers to respond quickly to market demands and customer feedback. A study by MarketsandMarkets indicates that the demand for CNC milling machines is expected to grow at a CAGR of 6.2% from 2020 to 2025, driven largely by the need for more customizable and scalable production options. This flexibility not only decreases lead times but also reduces production costs, as businesses can make adjustments to their designs without significant retooling. Overall, CNC milling technology is a crucial enabler of innovation in manufacturing, allowing for greater creativity and efficiency.

Impact of CNC Milling on Design Flexibility in Manufacturing

Why the Integration of CNC Milling Reduces Waste and Production Costs

CNC milling has become a cornerstone of modern manufacturing, significantly reducing both waste and production costs. According to a report by the Manufacturing Technology Association, integrating CNC milling techniques can result in material waste reduction by up to 30%. This efficiency is achieved through precise cutting and machining, allowing manufacturers to create complex parts with minimal excess material. The ability to program machines to execute specific tasks has revolutionized how materials are utilized, ensuring that every piece is crafted to exact specifications.

Moreover, the financial implications of adopting CNC milling are substantial. A study published in the Journal of Manufacturing Processes highlighted that companies utilizing CNC technology could see production cost reductions of 20-50% compared to traditional milling methods. This is primarily due to decreased labor costs and the reduction of downtime—CNC machines can operate continuously, only needing minimal supervision from skilled operators. By minimizing errors and rework, CNC milling not only streamlines the production process but also enhances overall profitability, reflecting a strategic move for manufacturers aiming to thrive in a competitive landscape.

Why CNC Milling Supports the Shift Towards Automation in Manufacturing Processes

CNC milling is playing a pivotal role in the ongoing shift toward automation within modern manufacturing processes. As industries increasingly adopt new digital manufacturing technologies, the impact on productivity is profound. The CNC machine market, projected to reach USD 170.4 billion by 2033, indicates a growing reliance on automated systems, with a compound annual growth rate (CAGR) of 9.80% from 2024 to 2033. This surge underscores the importance of CNC milling in enhancing efficiency and precision, thereby supporting the move toward automated operations.

Moreover, the integration of intelligent robotics with CNC systems is transforming traditional manufacturing paradigms. Automated solutions facilitate faster tool changes and improved material handling, which are critical for maintaining competitiveness in various sectors. As the CNC controller market is anticipated to expand significantly, reaching USD 12.4 billion by 2035, it is clear that robotics and AI are redefining machining processes. The intertwining of AI with CNC technology promises innovative advancements, ensuring that manufacturing not only keeps pace with demand but also capitalizes on efficiency gains enabled through automation.

Related Posts

-

Unlocking Precision: How CNC Machines Revolutionize Manufacturing Today

-

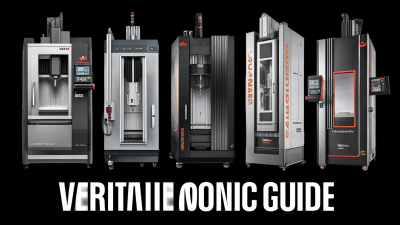

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

-

Ultimate Guide to the Top Five Vertical CNC Machines Compared for Best Performance

-

5 Reasons High Speed CNC Machining Can Boost Your Production Efficiency by 50 Percent

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

-

10 Must-Know Facts About CNC Processing to Boost Your Business Efficiency