- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

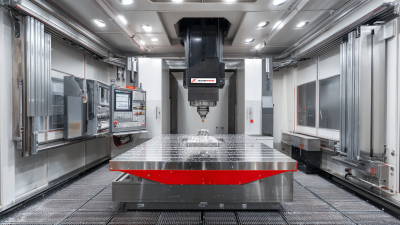

The Ultimate Guide to High Precision Machining for Global Buyers in 2023

In the ever-evolving landscape of manufacturing, high precision machining has emerged as a cornerstone of modern industrial processes, catering to the increasing demands for accuracy and efficiency. According to a report by MarketsandMarkets, the global high precision machining market is projected to reach USD 86.22 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is driven by advancements in technology and the rising need for sophisticated components in various sectors, including aerospace, automotive, and medical devices. As global buyers seek competitive edges through superior product quality and reduced production times, understanding the intricacies of high precision machining becomes imperative. This guide aims to equip buyers with comprehensive insights into the latest trends, technologies, and best practices that define high precision machining in 2023, ensuring informed decision-making in an increasingly complex marketplace.

Understanding High Precision Machining: Key Techniques and Technologies

High precision machining is rapidly becoming an essential component for industries requiring exact tolerances and intricate components. According to a report by Grand View Research, the global precision machining market was valued at $99.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6% through 2030. This surge is driven by the increasing demand for precision parts in industries such as aerospace, automotive, and medical devices, where even the smallest deviation can lead to significant performance issues.

Key techniques in high precision machining include advanced CNC (Computer Numerical Control) machining, electrical discharge machining (EDM), and laser cutting. CNC machining, which allows for automated controls to create complex shapes, has seen a significant increase in adoption due to its ability to produce components with tolerances as tight as ±0.0001 inches. Additionally, EDM is valued for its ability to machine hard metals with exquisite detail, making it indispensable in the tool and die manufacturing sector. The integration of these technologies not only enhances production efficiency but also improves quality assurance processes, ultimately benefiting global buyers looking for reliable and precise machining solutions.

The Ultimate Guide to High Precision Machining: Key Techniques and Technologies

Essential Factors for Selecting a High Precision Machining Supplier

When selecting a high precision machining supplier, it’s crucial to consider several essential factors that can significantly impact your project's outcome. According to a recent report from SME (Society of Manufacturing Engineers), the global market for precision machining is projected to grow from $60 billion in 2020 to $90 billion by 2025, indicating increased demand for quality and precision across various industries. This growth signifies a competitive landscape, necessitating careful supplier selection to ensure quality, reliability, and technological capabilities.

One key factor to evaluate is the supplier's technological proficiency. Suppliers with advanced CNC (Computer Numerical Control) machines and automated processes can provide tighter tolerances and superior quality. For instance, a study by Industry Week revealed that 73% of manufacturers reported improved production efficiency due to automation in precision machining. Additionally, checking certifications such as ISO 9001 or AS9100 can offer insights into a supplier's commitment to quality management systems. It is also essential to assess their capacity for scalability and adaptability to changing project requirements, ensuring that they can handle future growth efficiently.

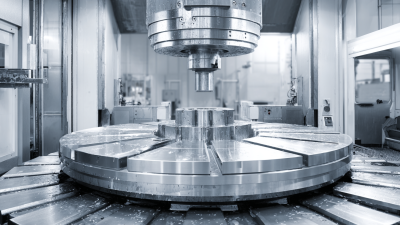

Exploring Different Applications of High Precision Machining Across Industries

In 2023, high precision machining is becoming increasingly vital across various industries, from aerospace to medical devices. This technique facilitates the production of components that require tight tolerances and exceptional accuracy, promoting higher quality standards and improved performance. As the global demand for such precision continues to grow, industries are finding innovative applications that enhance productivity and efficiency.

Tip: When selecting a high precision machining provider, ensure they utilize advanced technology and automated processes. This approach not only increases productivity but also significantly reduces the likelihood of defects, leading to more reliable outputs.

The expansion of the global machine tool market indicates a clear trend towards greater reliance on high precision solutions. As industries evolve, the integration of artificial intelligence and automation is reshaping conventional machining practices, allowing for real-time adjustments and analysis. This modernization can lead to production processes that are not just faster, but also smarter.

Tip: Keep an eye on emerging technologies in high precision machining. Staying abreast of innovations such as AI-assisted diagnostics can give your business a competitive edge, ensuring that you meet the evolving demands of your industry while maintaining quality and efficiency.

Common Challenges in High Precision Machining and How to Overcome Them

High precision machining presents a range of challenges that can complicate the manufacturing process for global buyers. Among the most common issues are material selection, tooling wear, and maintaining tight tolerances. Each of these factors can significantly impact production timelines and product quality, making it essential for buyers to identify strategies to mitigate these challenges.

One effective tip is to invest in high-quality materials that are specifically suited for precision machining. Understanding the properties of different materials not only helps in selecting the best option but can also reduce machining errors. Regularly reviewing and optimizing tooling conditions can also extend tool life and enhance machining precision. Moreover, utilizing advanced monitoring technologies can help maintain accuracy throughout the machining process.

Another critical aspect is thorough communication with manufacturers. Providing clear specifications and ensuring that both parties understand the project requirements can prevent misunderstandings that may lead to errors. Establishing strong relationships with suppliers who have a proven track record in high precision machining can also make a substantial difference in overcoming challenges and achieving the desired results.

Trends Shaping the Future of High Precision Machining in 2023 and Beyond

The landscape of high precision machining is rapidly evolving, driven by advancements in technology and changing market demands. By 2027, the global laser technology market is projected to reach a staggering $15.99 billion, reflecting a compound annual growth rate (CAGR) of 4.5% during the forecast period. This growth is indicative of the increasing adoption of CNC (Computer Numerical Control) machines, which are enhancing productivity across a wide array of industries. New digital manufacturing technologies are not just improving efficiency but also enabling manufacturers to transition towards more sustainable operational solutions, thereby addressing environmental concerns.

Moreover, the expansion of automation in the industry is further highlighted by the expected growth of the capping machine market, forecasted to exceed $2.31 billion by 2024. With a predicted CAGR of 5.9% from 2025 to 2034, this sector benefits from rising consumption of packaged goods and a push towards manufacturing automation. The jewelry manufacturing and precious metal processing equipment markets are similarly set to innovate, reflecting a trend towards the integration of automated and digital design tools. As these trends continue to shape the future, industry players must adapt to remain competitive and capitalize on the opportunities presented by high precision machining advancements.

Related Posts

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

-

Understanding Industry Production Standards for Optimal High Speed Machining Performance

-

Ultimate Checklist for Selecting the Best 5 Axis Machining Services

-

Top Strategies for Sourcing the Best High Precision Machining Solutions Worldwide

-

Ultimate Guide to the Top Five Vertical CNC Machines Compared for Best Performance