- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

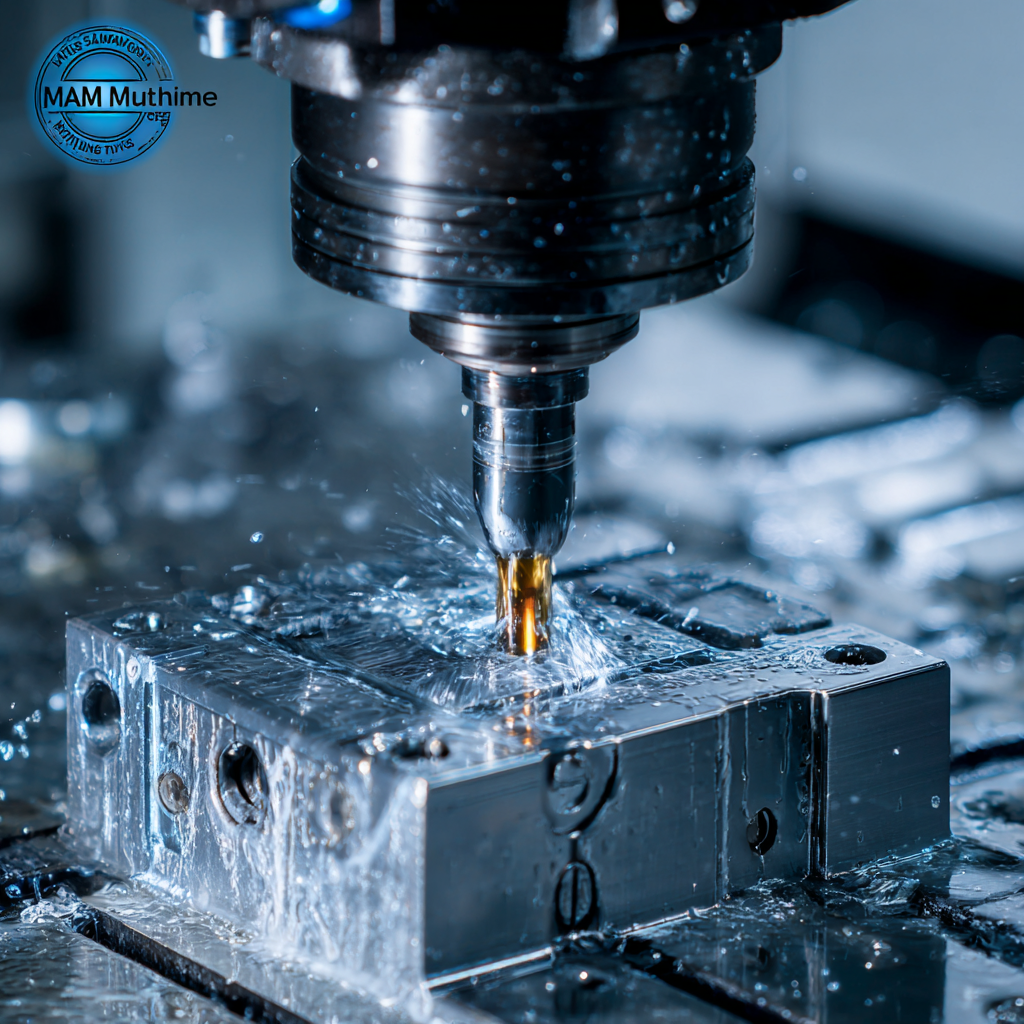

Exploring the Future of Best High Speed CNC Machining Innovations for 2025

As we venture into 2025, the landscape of high speed CNC machining is poised for transformative innovations that promise to redefine manufacturing efficiency and precision. According to a recent report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2025, demonstrating a significant compound annual growth rate (CAGR) of 4.5%. This surge is driven by the increasing demand for automation and the need for cost-effective solutions across various industries, such as aerospace, automotive, and medical devices. Innovations in high speed CNC machining technologies, including advanced tooling materials, software optimization, and integrated IoT systems, are set to enhance productivity and reduce cycle times. As we explore these emerging trends and innovations, it becomes essential to understand their implications on design and manufacturing processes in the years to come.

Exploring Key Trends Shaping High-Speed CNC Machining Innovations by 2025

As we approach 2025, the landscape of high-speed CNC machining is witnessing transformative advancements that are set to redefine manufacturing processes. Key trends shaping this innovation include the integration of artificial intelligence (AI) and machine learning technologies. According to a recent report from MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, with AI-driven solutions enhancing efficiency and precision. These technologies are helping manufacturers to optimize their operations, minimize waste, and reduce downtime significantly.

In addition, the development of advanced materials plays a vital role in high-speed CNC machining innovations. The use of composite materials is on the rise, offering improved strength-to-weight ratios and resistance to wear and tear. A study by Mordor Intelligence indicates that the market for these materials is expected to grow by over 15% annually in the coming years, emphasizing their importance in producing lighter and more durable components.

Tip: Consider investing in software that leverages predictive maintenance algorithms to monitor your CNC machinery. This can help you anticipate maintenance needs and avoid costly breakdowns.

Tip: Focus on training your workforce to adapt to these new technologies. Upskilling staff in the use of AI and advanced CNC systems will ensure that your company remains competitive in this evolving market.

Understanding Industry Standards: The Role of ISO 9001 in CNC Machining Quality

In the rapidly evolving landscape of CNC machining, industry standards play a pivotal role in ensuring quality and efficiency. A key standard influencing this sector is ISO 9001, which provides a framework for quality management systems. Research indicates that companies certified to ISO 9001 experience a 20% increase in operational efficiency and a significant reduction in errors, ultimately leading to enhanced customer satisfaction. As the industry gears up for innovations in high-speed CNC machining by 2025, adherence to ISO 9001 becomes crucial for businesses aiming to stay competitive.

The relevance of ISO 9001 in CNC machining cannot be overstated. According to a recent report by MarketsandMarkets, the global CNC machining market is projected to reach $100 billion by 2025, driven by advancements in technology and an increasing emphasis on precision manufacturing. Certification to ISO 9001 allows machining firms to demonstrate their commitment to quality, which is essential for attracting clients in a market driven by stringent quality demands. Furthermore, ISO 9001 certification helps mitigate risks associated with non-compliance, ensuring that organizations not only meet but exceed industry expectations in their machining processes.

The Impact of Automation: How AI and Robotics Are Revolutionizing CNC Machining Efficiency

The landscape of CNC machining is undergoing a profound transformation fueled by the integration of automation technologies. Artificial Intelligence (AI) is at the forefront of this revolution, optimizing processes from design to production. By utilizing machine learning algorithms, CNC machines can analyze vast amounts of data in real-time, predicting maintenance needs and reducing downtime. This predictive capability not only enhances operational efficiency but also minimizes costs associated with unexpected machine failures.

Robotics is another game-changer in the realm of CNC machining. Collaborative robots, or cobots, are designed to work alongside human operators, enhancing productivity without compromising safety. These robots can handle repetitive tasks with high precision, allowing skilled workers to focus on more complex and creative aspects of manufacturing. As the synergy between AI and robotics continues to evolve, we can anticipate a future where CNC machining is not only faster but also smarter, paving the way for innovative applications across various industries.

Emerging Materials: Innovations in Tooling and Surfaces for Enhanced Machining Performance

As we look ahead to 2025, the future of high-speed CNC machining will be substantially influenced by emerging materials that promise to enhance tooling and surfaces. Innovations in composite materials and ceramics are setting the stage for significant performance improvements, not only in durability but also in precision and efficiency. These advancements allow for faster cutting speeds and longer tool life, which directly translate to reduced downtime and cost savings for manufacturers.

When considering new tooling options, keep in mind the importance of selecting the right material for your specific machining application. Tools made from carbide composites can offer superior wear resistance, while advanced coatings can improve surface hardness and reduce friction. Investing in high-quality coatings and materials will ultimately lead to better machining performance and higher quality finished products.

Here are a couple of tips: First, always assess the compatibility of new materials with your existing CNC equipment to avoid potential issues. Second, stay updated on the latest research in machining technologies to identify which innovations can be integrated into your processes for maximum benefit. Embracing these emerging materials will not only enhance your machining capabilities but also position your operation at the forefront of the industry.

Cost-Benefit Analysis: Evaluating the Financial Impact of Adopting High-Speed CNC Technologies

As the manufacturing industry continues to evolve, the financial implications of adopting high-speed CNC (Computer Numerical Control) technologies remain a crucial consideration for businesses. A cost-benefit analysis reveals that while initial investments in advanced CNC machinery can be significant, the long-term savings and efficiency gains are often substantial. High-speed CNC machines can dramatically reduce machining time, leading to increased production rates and decreased labor costs. Additionally, the precision and quality of the output are markedly improved, minimizing waste and rework costs.

Tips for evaluating these technologies include conducting a thorough market analysis and obtaining quotes from multiple suppliers to benchmark costs. Businesses should also consider the potential for automation and integration with existing systems to enhance operational synergy. Calculating the ROI over a projected period not only helps in justifying the expenditure but also provides insight into the strategic benefits that high-speed CNC technology can bring to the organization’s manufacturing capabilities.

Moreover, examining case studies of similar companies that have adopted high-speed CNC solutions can provide valuable insights into financial impacts and operational enhancements. This evidence-based approach allows businesses to make informed decisions tailored to their specific needs and circumstances.