- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

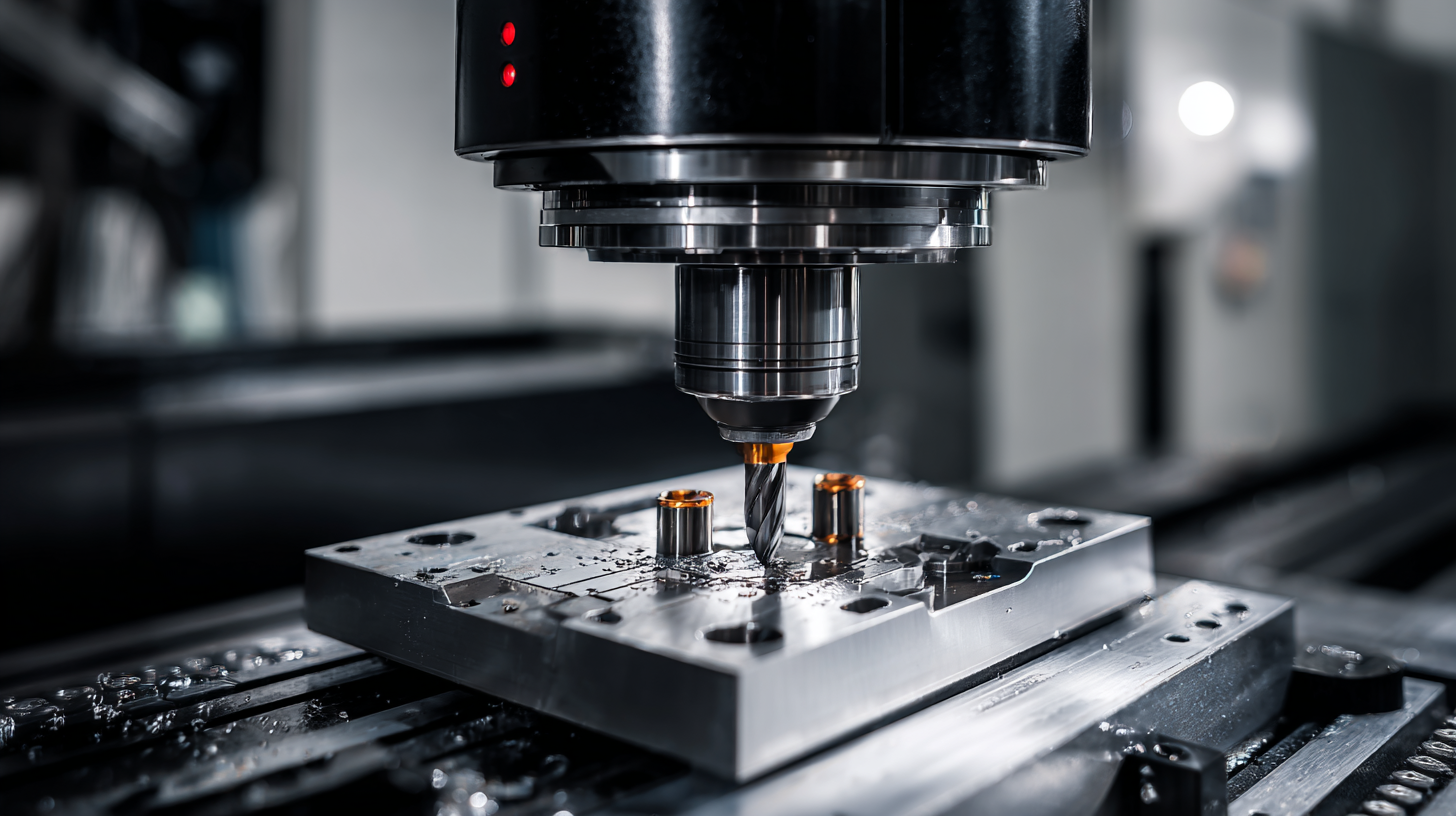

Understanding the Features of the Best CNC Machining Center for Your Business

In the rapidly evolving landscape of manufacturing, the importance of choosing the right equipment cannot be overstated. Among the various tools available, the CNC machining center stands out as a pivotal asset for businesses seeking precision, efficiency, and versatility in their production processes. As global manufacturing trends emphasize the balance between innovation and quality, understanding the features of the best CNC machining center becomes crucial for any enterprise. This blog delves into the essential characteristics that define top-tier CNC machining centers, focusing on how these features can enhance productivity and ensure superior output quality.

With China emerging as a leader in manufacturing excellence, businesses can harness the benefits of high-quality CNC machining centers to revolutionize their operations and stay competitive in today's market.

Key Specifications to Consider in CNC Machining Centers

When selecting a CNC machining center for your business, several key specifications should be taken into account to ensure you choose the best fit for your operational needs. First and foremost, the machining center's axis configuration is critical. Most centers come with three, four, or even five axes, and the right configuration depends on the complexity of the parts you intend to produce. A five-axis machine, for example, can significantly reduce the need for multiple setups and increase precision by allowing for intricate shapes to be cut from various angles.

Another essential specification is the spindle speed and torque. The spindle speed determines how quickly the machining center can perform cutting operations, while torque influences the machine's ability to handle various materials effectively. A machine with high spindle speed is beneficial for lighter materials, while higher torque is necessary for machining harder metals.

Additionally, consider the tool capacity and automation features. A center with a larger tool carousel or automatic tool changer can dramatically improve efficiency by reducing downtime due to tool changes, making your production processes more streamlined.

These specifications will help in choosing a CNC machining center that enhances productivity and meets your specific manufacturing goals.

Evaluating Accuracy and Precision in Different CNC Models

When selecting a CNC machining center for your business, evaluating accuracy and precision across different models is crucial. High-precision machining plays a pivotal role in meeting the increasing demands of modern industrial manufacturing. Recent advancements such as optimized dual NURBS curve interpolation and geometric error compensation software for five-axis machines showcase the cutting-edge technologies enhancing machining accuracy. These innovations not only facilitate intricate path planning but also compensate for potential geometric errors, ensuring superior finished products.

**Tip:** When assessing different CNC models, consider those that implement machine learning algorithms for enhanced precision. These technologies can significantly improve the stability of machining operations, ultimately reducing error rates.

Moreover, understanding the sources of error in CNC operations is essential. Studies have identified various factors influencing accuracy, including the performance of linear motor feed systems and the milling processes. Implementing predictive models, such as data-augmentation long short-term memory networks, can further optimize manufacturing processes and bolster precision.

**Tip:** Invest in CNC systems that allow for regular performance assessments and have built-in capabilities for error detection. This proactive approach ensures that your machinery maintains high accuracy over time, keeping your production standards high.

Understanding the Features of the Best CNC Machining Center for Your Business

| CNC Model | Accuracy (µm) | Precision (µm) | Max Spindle Speed (RPM) | Work Area (mm) | Control System |

|---|---|---|---|---|---|

| Model A | 5 | 3 | 12000 | 1000 x 600 | Fanuc |

| Model B | 4 | 2 | 15000 | 1200 x 800 | Siemens |

| Model C | 3 | 1 | 18000 | 800 x 500 | Mitsubishi |

| Model D | 2 | 1.5 | 20000 | 1500 x 1000 | Heidenhain |

Comparing Automation Features Across Leading CNC Machining Centers

When comparing automation features across leading CNC machining centers, it's essential to focus on how these advancements can streamline operations and enhance productivity. Automated CNC machines are designed not only for efficiency but also for precision, as seen in the latest research utilizing machine learning for fault diagnosis. By monitoring three-axis vibration data, these systems can significantly reduce downtime caused by mechanical failures, allowing businesses to maintain optimal production schedules.

Moreover, the transition from vertical to horizontal machining centers highlights the advantages of automation in terms of space management and process efficiency. Horizontal machining centers are equipped to handle multitasking operations, enabling the completion of complex parts in a single setup. This eliminates the need for multiple machines and setups, thus reducing operational costs while improving overall part accuracy. As businesses look towards the future, incorporating advanced automation features in CNC machining centers is not just a trend but a strategic move to stay competitive in a rapidly evolving manufacturing landscape.

Assessing Material Compatibility and Efficiency in CNC Machines

When selecting a CNC machining center for your business, understanding the compatibility of materials with your machining processes is essential for optimizing efficiency. Recent advancements in machining technologies, such as wire arc additive manufacturing (WAAM), have highlighted the importance of material properties and processing techniques. By utilizing direct energy deposition methods, manufacturers can improve the way they stack and fuse materials, creating complex geometries while enhancing the overall efficiency of production processes.

Moreover, the evolution of advanced engineering materials, particularly in composites like the LM25 aluminum alloy reinforced with vanadium carbide, opens new avenues for machining operations. Analyzing machinability and applying advanced modeling techniques, such as deep neural networks, can lead to significant improvements in economic outcomes and environmental sustainability. Incorporating these modern techniques helps businesses assess not only the compatibility of materials but also the long-term implications on operational efficiency and environmental impact. As manufacturers continually seek to refine their processes, understanding these factors will be crucial in maintaining a competitive edge in the industry.

Understanding Cost vs. Performance in CNC Machining Investment Choices

When investing in CNC machining centers, understanding the balance between cost and performance is critical for businesses aiming for efficiency and profitability. According to a recent report by SME (Society of Manufacturing Engineers), businesses can experience a return on investment (ROI) of up to 300% when selecting high-performance CNC machines that meet their specific operational needs. Thus, while the initial cost of advanced CNC centers may be significant, the long-term gains through enhanced productivity and precision can justify the investment.

Moreover, a study by Research and Markets indicates that the global CNC machining market is expected to grow substantially, reaching a value of over $100 billion by 2026, driven by the demand for automation and high-quality manufacturing processes. Companies must carefully evaluate their options, weighing not just the purchase price but also the operational efficiencies and output quality that advanced CNC machining centers provide. By investing in machines that might have a higher upfront cost, manufacturers can capitalize on improved throughput, reduced scrap rates, and greater flexibility, ultimately ensuring a more competitive edge in the market.