- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

How to Enhance Precision and Efficiency with 3 Axis CNC Milling Machines in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the integration of advanced technologies is paramount for improving precision and efficiency. One such pivotal technology is the 3 axis CNC milling machine, which has transformed traditional machining processes. According to a report by Market Research Future, the global CNC milling machines market is projected to reach USD 5.26 billion by 2025, growing at a CAGR of 6.45%. This surge underscores the increasing adoption of CNC technology across various sectors, driven by the need for enhanced accuracy and reduced production times.

Small to medium enterprises (SMEs), which account for nearly 70% of the manufacturing industry, are increasingly leveraging 3 axis CNC milling machines to facilitate cost-effective production methods while maintaining high-quality standards. By optimizing workflows and minimizing human error, these machines not only bolster productivity but also enable manufacturers to meet the demands of a competitive marketplace.

Maximizing Production Efficiency with 3 Axis CNC in Small to Medium Enterprises

In the competitive landscape of modern manufacturing, small to medium enterprises (SMEs) are increasingly turning to 3-axis CNC milling machines as a means to enhance production efficiency. These versatile machines allow for the intricate machining of components with precision, significantly reducing the time and labor costs associated with traditional manufacturing processes. By automating complex tasks, SMEs can streamline operations, minimize human error, and achieve high-quality results in less time.

Furthermore, integrating 3-axis CNC milling into production workflows enables SMEs to remain agile and responsive to market demands. With the capability to execute multiple machining operations in a single setup, businesses can optimize their production schedules and reduce downtime. This flexibility not only accelerates lead times but also enhances the potential for innovation, as companies can experiment with new designs without the burden of extensive overhead. Embracing such technology allows SMEs to compete effectively in a rapidly evolving industry, ultimately leading to increased profitability and sustainable growth.

The Role of Precision in Achieving Competitive Advantage through CNC Milling

The role of precision in modern manufacturing cannot be overstated, particularly when it comes to CNC milling. In a competitive landscape, precision machining serves as a critical differentiator, allowing companies to deliver products that meet stringent quality standards. CNC milling machines equipped with 3-axis technology excel in producing complex geometries with a high degree of accuracy, enabling manufacturers to create components that fit perfectly within larger assemblies. This level of precision not only minimizes waste and rework but also enhances overall productivity, translating to reduced manufacturing costs.

Moreover, achieving competitive advantage through precision CNC milling involves investing in advanced technology and skilled operators. As the market demands increasingly intricate designs, manufacturers must leverage the capabilities of 3-axis CNC machines to push the boundaries of traditional machining. This commitment to precision leads to improved customer satisfaction, as clients receive products that not only perform better but also have longer service lives. Ultimately, precision in CNC milling is not just about meeting specifications; it is about setting new benchmarks within the industry, fostering innovation, and maintaining leadership in a rapidly evolving marketplace.

Integrating Advanced Software for Enhanced Precision in CNC Machining Processes

In modern manufacturing, the integration of advanced software with 3 Axis CNC milling machines is paramount to enhancing precision and efficiency in machining processes. Software solutions equipped with sophisticated algorithms facilitate optimal tool path generation, ensuring that the machining operations are executed with a high level of accuracy. This not only minimizes material waste but also reduces production time, allowing manufacturers to meet tight deadlines without compromising on quality.

Moreover, advanced software often features simulation capabilities that enable operators to visualize machining processes before actual production begins. This proactive approach helps identify potential errors or collisions, significantly lowering the risk of costly machine downtime and the need for reworks. Incorporating such software tools into the CNC machining workflow cultivates an environment where innovation and precision go hand in hand, positioning businesses to overcome the challenges of modern manufacturing while maximizing their operational output.

Cost-Benefit Analysis: Investment in 3 Axis CNC vs Traditional Manufacturing Methods

Investing in 3-axis CNC (Computer Numerical Control) milling machines presents significant advantages over traditional manufacturing methods, particularly in precision and efficiency. According to a report by Technavio, the CNC machine market is projected to grow by over $7 billion between 2020 and 2024, highlighting the increasing adoption of advanced manufacturing technologies. The enhanced precision offered by 3-axis CNC machines allows manufacturers to create intricate designs with tolerances as tight as ±0.005 mm, significantly reducing material waste and leading to cost savings.

Moreover, a cost-benefit analysis reveals that while the initial investment for 3-axis CNC equipment can be substantial—ranging from $10,000 to $150,000 depending on specifications—the long-term savings can be remarkable. A study by Deloitte indicates that companies employing CNC technology can reduce production lead times by up to 50%, while also improving product quality and consistency. This reduction in cycle time translates to increased throughput and the ability to meet tighter deadlines, ultimately enhancing competitive advantage in today’s fast-paced market. Thus, the shift to 3-axis CNC milling not only drives operational efficiency but also offers a compelling return on investment compared to traditional machining methods.

How to Enhance Precision and Efficiency with 3 Axis CNC Milling Machines in Modern Manufacturing - Cost-Benefit Analysis: Investment in 3 Axis CNC vs Traditional Manufacturing Methods

| Criteria | 3 Axis CNC Milling Machines | Traditional Manufacturing Methods |

|---|---|---|

| Initial Investment | $50,000 - $150,000 | $20,000 - $100,000 |

| Operational Cost (per hour) | $20 - $50 | $30 - $70 |

| Production Speed (units/hour) | 10 - 30 | 5 - 15 |

| Precision (mm) | 0.01 - 0.05 | 0.1 - 0.5 |

| Setup Time (hours) | 1 - 2 | 2 - 5 |

| Worker Skill Level | Moderate | High |

| Maintenance Frequency (per year) | 2 - 4 | 5 - 10 |

| Return on Investment (ROI) | 20% - 35% | 10% - 15% |

Future Trends: Automation and IoT in Precision 3 Axis CNC Milling Techniques

The integration of Automation and the Internet of Things (IoT) in 3 Axis CNC milling techniques marks a transformative shift in modern manufacturing. By harnessing these technologies, manufacturers can achieve unprecedented precision and efficiency, streamlining processes and minimizing errors. IoT-enabled machines can collect real-time data, allowing for predictive maintenance and reducing downtime. This intelligent connectivity enhances operational workflows, enabling manufacturers to monitor equipment performance from anywhere, improving decision-making and production outcomes.

Tips for implementing automation in CNC milling include starting with a thorough assessment of your current workflows to identify areas where IoT can provide the most significant impact. Investment in compatible sensors can help gather data crucial for optimizing machine performance. Additionally, consider adopting software solutions that facilitate data analysis and implement machine learning algorithms to predict failures before they occur, ensuring a smoother production process.

As the landscape of manufacturing evolves, embracing trends like automation and IoT will be essential for staying competitive. Ensure that your workforce is properly trained to adapt to these new technologies. Continuous education will empower employees to make the most of these innovations, leading to higher productivity and improved product quality in the face of growing market demands.

Related Posts

-

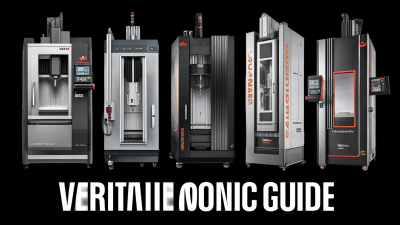

Ultimate Guide to the Top Five Vertical CNC Machines Compared for Best Performance

-

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

-

The Ultimate Guide to High Precision Machining for Global Buyers in 2023

-

Understanding Industry Production Standards for Optimal High Speed Machining Performance

-

7 Secrets to Finding the Best CNC Precision Machining Suppliers Worldwide

-

5 Reasons the Best High Speed CNC Machines Boost Production Efficiency by 30%