- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Unlocking Precision: How CNC Machines Revolutionize Manufacturing Today

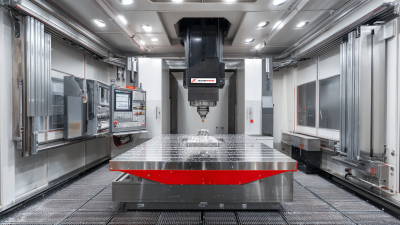

In recent years, CNC machines have emerged as a transformative force in the manufacturing industry, driving unprecedented levels of precision and efficiency. According to a report by MarketsandMarkets, the global CNC machine market is expected to reach $117.24 billion by 2026, growing at a CAGR of 8.4% from 2021. This growth is largely attributed to the increasing demand for automation, which enhances productivity, reduces waste, and enables complex designs that were previously impossible with traditional machining methods. As industries strive to stay competitive in a rapidly evolving marketplace, the adoption of CNC machines is not just a trend but a necessity.

With applications spanning from aerospace to automotive and medical sectors, the ability to produce high-precision parts with minimal human intervention makes CNC machines a pivotal element in the future of manufacturing.

Benefits of CNC Machines: Achieving Tolerance Levels of Up to ±0.005 Inches

CNC (Computer Numerical Control) machines are transforming the landscape of modern manufacturing through their unparalleled precision and efficiency. Achieving tolerance levels of up to ±0.005 inches, CNC technology has become essential in industries such as aerospace, automotive, and medical device manufacturing. According to a recent industry report from MarketsandMarkets, the global CNC machine market is projected to reach $100 billion by 2025, highlighting the increasing reliance on this technology for high-precision applications.

One of the key benefits of CNC machines is their ability to produce complex parts with remarkable consistency. Traditional manufacturing processes often struggle with maintaining tight tolerances, leading to increased waste and rework. In contrast, CNC machines utilize computer-controlled movements that significantly enhance cutting accuracy, allowing manufacturers to streamline production while maintaining exceptional quality standards. According to a study published by McKinsey, companies that adopt CNC machining can reduce production costs by up to 25%, while also improving lead times by as much as 50%.

**Tips for Optimizing CNC Machining:**

- Regularly maintain and calibrate your CNC machine to ensure optimal performance and accuracy.

- Utilize advanced simulation software to plan and test machining processes, minimizing errors and waste before actual production.

- Invest in high-quality cutting tools and materials to achieve the best performance and longevity from your CNC equipment.

Unlocking Precision: How CNC Machines Revolutionize Manufacturing Today

| Aspect | CNC Machines | Traditional Methods |

|---|---|---|

| Tolerance Level | ±0.005 Inches | ±0.020 Inches |

| Production Speed | High | Moderate |

| Material Versatility | Wide Range | Limited |

| Setup Time | Short | Long |

| Labour Cost | Lower | Higher |

| Customization Capabilities | High | Limited |

CNC Machining Trends: A 25% Annual Growth Rate in the Global Market

The global CNC machining market is witnessing unprecedented growth, projected to expand by 25% annually, reflecting a robust demand for precision manufacturing. According to a market research study by Custom Market Insights, this surge is driven by the increasing need for enhanced accuracy and efficiency across various industries. The global demand for CNC metal components is expected to see substantial increases, further solidifying the technology's pivotal role in modern manufacturing.

In parallel, various sectors are experiencing transformative changes influenced by technological advancements. For instance, the 2025 Manufacturing Industry Outlook emphasizes the imperative for manufacturers to invest in digital technologies to enhance innovation and address the persistent skills gap. This proactive approach is essential not only for competitiveness but also for the adaptation to emerging trends, such as the integration of artificial intelligence into manufacturing processes, which is also poised to significantly influence the industry landscape. As these dynamics unfold, CNC machines will be at the forefront, shaping the future of manufacturing with precision-driven solutions.

Unlocking Precision: CNC Machining Trends and Market Growth

The global CNC machining market is experiencing significant growth, projected to achieve a 25% annual growth rate. This chart visualizes the expected market growth from 2023 to 2028.

The Role of Automation: Enhancing Efficiency by Up to 50% in Production Lines

The role of automation in manufacturing has become increasingly pivotal, with recent studies indicating that the integration of automated systems in production lines can enhance efficiency by up to 50%. According to a report by McKinsey, companies that have adopted automation technologies have seen a significant reduction in manual errors and an increase in output quality. By leveraging CNC (Computer Numerical Control) machines, manufacturers are not only streamlining their processes but also achieving precision that is often unattainable through traditional methods.

These advancements in CNC technology allow for intricate designs and complex geometries to be produced with remarkable accuracy. A study from the National Institute of Standards and Technology (NIST) suggests that factories employing CNC machines can reduce their scrap rates by up to 90% compared to older manufacturing techniques. This not only cuts costs but also contributes to sustainability efforts by minimizing waste. As manufacturers continue to embrace automation, we are witnessing a transformative shift that positions CNC machining as a cornerstone of modern manufacturing efficiency.

Material Versatility: CNC Machines Capable of Working with 30+ Different Materials

CNC machines have transformed modern manufacturing through their ability to precision-engineer components across a vast range of materials. According to a recent report by MarketsandMarkets, the global CNC machine market is expected to grow from $70 billion in 2021 to $100 billion by 2026, demonstrating an increasing reliance on these versatile machines. With the capacity to work with over 30 different materials, including metals, plastics, wood, and composites, CNC technology has become an indispensable tool in sectors like aerospace, automotive, and medical device manufacturing.

One of the key advantages of CNC machines is their adaptability to various material characteristics, which allows for the creation of intricate designs with heightened accuracy and reduced waste. For instance, a study by McKinsey highlights that companies employing CNC machining have reduced material waste by up to 30%, significantly cutting costs and contributing to sustainability efforts. By utilizing different tools and settings, manufacturers can optimize machining for materials ranging from aluminum alloys to high-density polyethylene, ensuring superior quality and durability in their final products.

**Tip:** When selecting materials for CNC machining, consider both the mechanical properties and the machining characteristics to achieve the best results. Testing different combinations can help identify optimal settings and tooling options for your manufacturing needs.

**Tip:** Regular maintenance of CNC machines is crucial. Ensure your equipment is calibrated correctly to maintain accuracy, especially when switching materials, as different materials can affect machining parameters significantly.

Cost Efficiency: Reducing Production Costs by 30% Through CNC Technology Integration

The integration of CNC (Computer Numerical Control) technology in manufacturing has proven to be a game-changer, particularly in terms of cost efficiency. A study by IBISWorld indicates that companies leveraging CNC machines can reduce production costs by up to 30%. This significant reduction is primarily due to enhanced precision and decreased waste, as CNC machines operate with remarkable accuracy, minimizing errors that can lead to costly rework. As machines automatically adjust for variations in material and tooling, manufacturers can maintain consistent quality while streamlining their operations.

Moreover, the adoption of CNC technology often leads to improved turnaround times. According to a report from Grand View Research, the global CNC machine market is expected to reach USD 100 billion by 2025, with iterative advancements leading to faster and more efficient production processes. As businesses increasingly recognize the potential for cost savings and efficiency gains, integrating CNC systems becomes not merely an option but a strategic imperative. This evolution not only paves the way for higher profit margins but also positions firms to better compete in an ever-evolving marketplace.

Related Posts

-

5 Reasons High Speed CNC Machining Can Boost Your Production Efficiency by 50 Percent

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

-

10 Must-Know Facts About CNC Processing to Boost Your Business Efficiency

-

The Ultimate Guide to High Precision Machining for Global Buyers in 2023

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Ultimate Comparison of the Top 5 CNC Vertical Machining Centers: Performance Metrics and ROI Analysis for Global Buyers