- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Top 10 Benefits of CNC Cutting for Your Manufacturing Needs

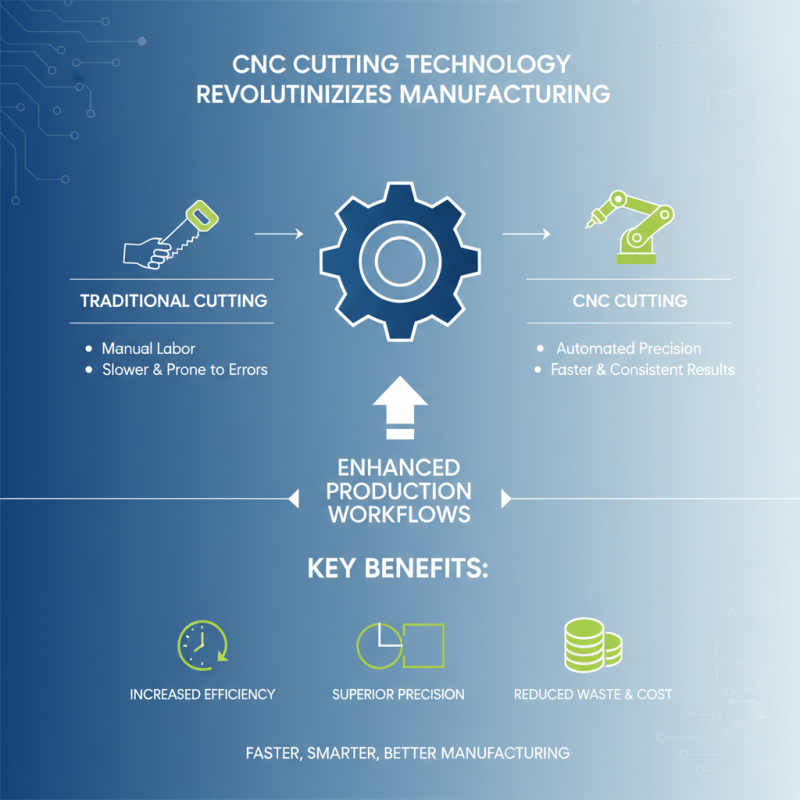

In the fast-evolving world of manufacturing, efficiency and precision are paramount. One of the most significant advancements in this field has been the incorporation of CNC cutting technology. CNC cutting, short for Computer Numerical Control cutting, utilizes computer-driven systems to guide machine tools in precision cutting processes. This innovative method has transformed traditional manufacturing techniques, offering a multitude of benefits that can significantly enhance production workflows.

The adoption of CNC cutting is not just about technological progress; it represents a pivotal shift towards more streamlined and accurate manufacturing processes. By minimizing human error and maximizing productivity, CNC cutting enables manufacturers to meet rigorous quality standards while reducing operational costs. Furthermore, the versatility of CNC cutting allows for the processing of various materials with remarkable precision, catering to a diverse range of industry needs. As we delve into the top ten benefits of CNC cutting, it becomes evident that this technology is not merely an option but a necessity for modern manufacturing excellence.

Understanding CNC Cutting Technology and Its Applications

CNC cutting technology has revolutionized the manufacturing landscape, offering precision and efficiency that traditional methods cannot match. According to a recent industry report by the International Federation of Robotics, CNC machines account for over 35% of all robotic installations in manufacturing, highlighting their growing importance. This technology utilizes computer numerical control to direct machinery with high levels of accuracy, making it ideal for industries such as aerospace, automotive, and electronics. The ability to produce complex parts with minimal human intervention not only enhances productivity but also significantly reduces the likelihood of errors, leading to improved product quality.

Moreover, the adaptability of CNC cutting technology allows for a diverse range of applications. From laser cutting metals to waterjet cutting materials like glass and stone, the versatility is striking. According to a market analysis conducted by Research and Markets, the global CNC cutting machine market is projected to reach $9.6 billion by 2025, driven by increased demand for custom manufacturing solutions. This surge indicates a broadening acceptance of CNC technology across various sectors, emphasizing its role in streamlining production processes and enabling just-in-time manufacturing strategies. The capacity for rapid prototyping further facilitates faster product development cycles, allowing manufacturers to respond swiftly to market demands.

Enhanced Precision and Accuracy in Manufacturing Processes

CNC cutting technology has revolutionized the manufacturing industry by providing

enhanced precision and accuracy in various processes. Unlike traditional cutting methods, CNC

(Computer Numerical Control) cutting utilizes computer software to control machinery with remarkable precision. This results in

consistently uniform products, minimizing human error. The ability to create intricate designs and complex geometries with

high fidelity is a significant advantage for manufacturers, enabling them to produce parts that meet stringent specifications

and quality standards.

When implementing CNC cutting in your manufacturing processes,

here are a few tips to maximize precision. First, ensure that your machinery is calibrated correctly and regularly maintained

to avoid any discrepancies in operation. Also, investing time in training your operators can significantly enhance the overall

output quality. This knowledge enables them to troubleshoot minor issues and adjust settings to optimize precision. Lastly,

using advanced software for design can streamline the programming process, allowing for more complex designs while maintaining

accuracy during production.

Another benefit of CNC cutting is its adaptability to various materials, from metals

to plastics. This flexibility means you can achieve the desired precision regardless of the medium being used. As you explore

CNC cutting, remember that the choice of tools and materials will also affect the final outcome. Ensure that you select

appropriate cutting tools that are compatible with your chosen materials to prevent wear and ensure a clean cut.

Increased Efficiency and Speed in Production Workflows

CNC cutting technology has revolutionized manufacturing by significantly enhancing production workflows. One of the primary advantages is the remarkable increase in efficiency. Traditional cutting methods often involve more manual labor and longer processing times, which can lead to inconsistencies and delays. In contrast, CNC machines operate with precision and speed, allowing for rapid execution of complex designs. This automation minimizes human error and boosts the overall productivity of manufacturing processes.

Furthermore, the speed at which CNC cutting operates plays a crucial role in meeting tight deadlines and increasing output. With the capability to run multiple jobs simultaneously, CNC machines can effectively handle large volumes of work without sacrificing quality. This capability not only accelerates production but also enables manufacturers to respond swiftly to market demands and customer needs. Consequently, businesses can maintain a competitive edge by delivering products faster and with greater accuracy, solidifying their position in the industry.

Cost-Effectiveness and Material Conservation Benefits

CNC cutting technology has revolutionized the manufacturing landscape, providing significant cost-effectiveness and material conservation benefits for businesses. This precision machining method minimizes waste by cutting materials into exact sizes, resulting in optimal usage of resources. By reducing scrap material, manufacturers not only lower their production costs but also contribute to a more sustainable business model. The ability to use various materials maximally enhances profit margins while ensuring high-quality outputs.

When utilizing CNC cutting, it’s essential to plan your production processes meticulously. One tip is to conduct a thorough analysis of your cutting patterns to identify the most efficient arrangements for your materials. This helps in determining the best way to minimize scrap. Additionally, employing software that can simulate cutting processes can help optimize the designs before actual production, further reducing waste.

Another key benefit of CNC cutting is the precision it offers, which directly correlates to material conservation. Maintaining tight tolerances means that parts fit together more seamlessly, leading to less rework and reduced material expenditure. Therefore, integrating CNC technology into your manufacturing operations not only enhances product quality but also promotes a more responsible approach to resource use and cost management.

Top 10 Benefits of CNC Cutting for Your Manufacturing Needs - Cost-Effectiveness and Material Conservation Benefits

| Benefit | Description | Impact |

|---|---|---|

| Cost-Effectiveness | CNC cutting minimizes waste, reducing material costs. | Lower production costs. |

| Precision Cutting | Achieves high precision and repeatability. | Improved product quality. |

| Flexibility | Can handle a variety of materials and designs. | Increased design versatility. |

| Material Conservation | Maximizes material use through efficient layouts. | Reduced waste and costs. |

| Speed | Rapid cuts reduce production time. | Faster time to market. |

| Safety | Minimizes exposure to dangerous manual cutting tools. | Enhanced workplace safety. |

| Automation | Automated processes reduce manual errors. | Increased efficiency. |

| Scalability | Easily scale production to meet demand. | Adapts to changing production needs. |

| Customization | Easily create custom designs for clients. | Higher customer satisfaction. |

| Reduced Lead Times | Shorter production cycles lead to quicker order fulfillment. | Improved responsiveness to customer needs. |

Versatility in Material Compatibility and Design Flexibility

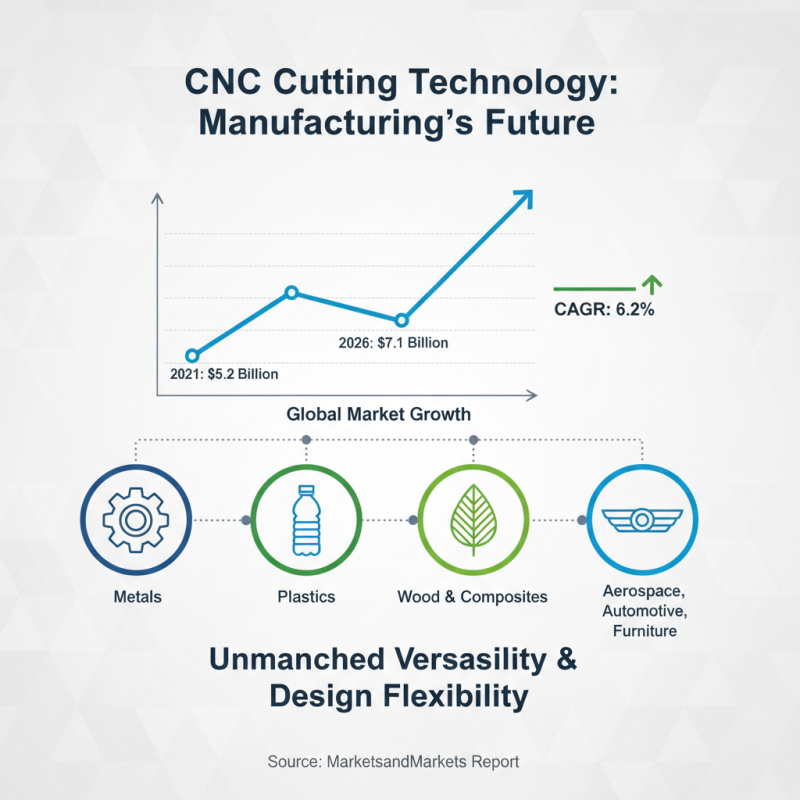

CNC cutting technology has revolutionized manufacturing processes, offering unmatched versatility in material compatibility and design flexibility. With the ability to handle a wide range of materials, including metals, plastics, wood, and composites, CNC cutting caters to diverse industries such as aerospace, automotive, and furniture manufacturing. According to a report by MarketsandMarkets, the global CNC cutting machine market is projected to grow from USD 5.2 billion in 2021 to USD 7.1 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.2%. This upward trend underscores the technology's adaptability to various materials and its integral role in modern manufacturing.

Furthermore, CNC cutting allows for intricate designs that traditional methods cannot achieve. The precision and repeatability of CNC systems enable manufacturers to create complex geometries and detailed patterns with minimal waste. A study by Technavio indicates that the increasing demand for customization in products will drive the growth of CNC machines in the coming years. This flexibility not only enhances product quality but also allows manufacturers to respond swiftly to changing market trends and consumer preferences. The integration of computer-aided design (CAD) software with CNC cutting processes further empowers designers to experiment with innovative shapes and structures, ultimately leading to enhanced design capabilities in the manufacturing landscape.

Related Posts

-

Understanding Global Industry Standards for Best CNC Machining Precision Production

-

Exploring the Future of Best High Speed CNC Machining Innovations for 2025

-

Unlocking Precision: How CNC Machines Revolutionize Manufacturing Today

-

Exploring the Impact of CNC Milling on Modern Manufacturing Techniques

-

Unlocking Precision: The Essential Guide to 5 Axis Milling Machines for Modern Manufacturing

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine