- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

How to Choose the Best Milling Machines for Your Projects

Choosing the best milling machines for your projects is a crucial decision that can significantly impact the efficiency and quality of your work. As the manufacturing sector evolves, the demand for advanced milling machines continues to grow, with a projected market value reaching approximately $4.1 billion by 2026, according to recent industry reports. This growth is driven by the increasing need for precision engineering across various sectors, including aerospace, automotive, and metalworking.

When selecting milling machines, it is essential to consider factors such as the machine's versatility, size, and capabilities. Recent data highlights that modular and CNC milling machines are becoming increasingly popular due to their adaptability and precision, with CNC units expected to dominate the market, accounting for around 60% of total milling machine sales by 2025. Additionally, understanding the specific requirements of your projects—like the materials you'll be working with and the desired accuracy—will help you make an informed choice, ensuring that your investments align with both current and future project demands.

Understanding the Basics of Milling Machines and Their Types

Milling machines are essential tools in various industrial sectors, providing precision and efficiency in material removal processes. Understanding the basics of milling machines and their types is crucial for selecting the right machine for your projects. There are primarily two categories of milling machines: vertical and horizontal. Vertical milling machines stand out with their versatile operations, allowing for the machining of complex shapes. According to a recent industry report, approximately 35% of all milling machine users favor vertical models for their adaptability in multi-purpose tasks.

In addition to machine types, features such as the spindle speed, table size, and feed rates are fundamental considerations when choosing a milling machine. Spindle speed is particularly vital, as it directly affects the material removal rate and surface finish quality. Data from manufacturing analysis indicates that machines operating at higher speeds can significantly reduce production time by as much as 25%, making them highly efficient for high-demand projects.

**Tips:** When selecting a milling machine, assess the specific requirements of your projects, including the material type and complexity. Additionally, consider machines with advanced controls that enhance automation and precision, enhancing productivity and reducing human error. Investing in quality tools tailored to your needs is crucial for achieving optimal results in your milling operations.

How to Choose the Best Milling Machines for Your Projects

| Type of Milling Machine | Features | Best For | Average Price Range |

|---|---|---|---|

| Vertical Milling Machine | Allows vertical movement of the spindle | Small to medium projects | $1,000 - $10,000 |

| Horizontal Milling Machine | Features a horizontal spindle | Large-scale manufacturing | $3,000 - $30,000 |

| CNC Milling Machine | Computer-controlled for precision | High precision parts | $10,000 - $100,000 |

| Bench Milling Machine | Compact size for small shops | Hobbyists and DIY projects | $500 - $3,000 |

| Universal Milling Machine | Versatile for different milling tasks | Custom and complex parts | $5,000 - $40,000 |

Key Features to Consider When Selecting a Milling Machine

When selecting a milling machine, understanding key features is crucial to ensuring the right fit for your projects. One of the primary considerations is the machine's size and capacity. A small benchtop model may suffice for hobbyists tackling lighter materials, while more extensive projects often demand larger, industrial-grade machines with higher horsepower and larger table dimensions. According to the "Market Research Future" report, the global milling machine market is projected to grow at a CAGR of around 5.4% from 2021 to 2026, signaling a robust demand for versatile and efficient models.

Another critical feature is the type of milling operation. Milling machines can be categorized into vertical and horizontal types, each designed for specific tasks. Vertical milling machines are generally more suitable for precision tasks and complex shapes, while horizontal machines are ideal for heavy-duty operations. Operators should also consider the machine's rigidity and stability, as these factors significantly influence machining accuracy and surface finish. A study by the “International Journal of Engineering Research & Technology” highlights that improved stability can enhance production quality and reduce operational costs.

Tips: Before making a purchase, assess your long-term project needs to ensure your milling machine can adapt to future applications. Additionally, pay attention to user reviews and performance benchmarks to understand how different machines handle various tasks. Exploring training resources or user manuals can also provide insights into maintaining optimal performance and safety.

Assessing the Size and Space Requirements for Your Projects

When choosing a milling machine for your projects, assessing the size and space requirements is crucial. The dimensions of the machine directly impact not only its performance but also the layout of your workspace. Before making a decision, consider the overall footprint of the milling machine, including any additional equipment you may need, such as associated tools or material storage. It's essential to measure the area you have available to ensure that the machine fits comfortably and allows for safe operation.

In addition to the machine's dimensions, think about the vertical and horizontal clearance needed for movement and access. Certain projects may necessitate larger or more complex setups, requiring more space than standard models provide. Evaluating these space requirements ahead of time will help avoid any potential operational interruptions later on, enabling a smoother workflow. By taking the time to assess and plan your workspace, you can choose a milling machine that not only meets your project's needs but also enhances your overall efficiency and effectiveness.

How to Choose the Best Milling Machines for Your Projects

This chart illustrates the number of projects suitable for different sizes of milling machines. The compact milling machines are best for smaller projects, while mid-size and floor model machines can accommodate larger undertakings.

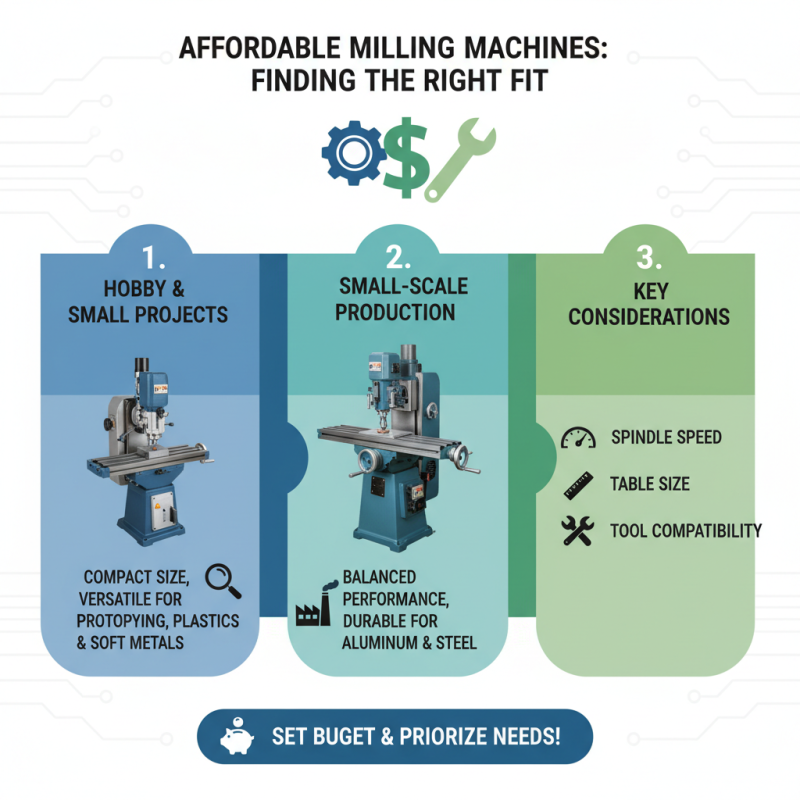

Exploring Budget Options: Finding Affordable Milling Machines

When exploring budget options for milling machines, it's essential to prioritize your project needs while staying within a financial limit. Affordable milling machines can be found in various forms, ranging from compact models perfect for hobbies to larger machines suitable for small-scale production. Assessing the specific tasks you need a milling machine for will help you stay focused on features that matter most, such as spindle speed, table size, and tool compatibility.

**Tips:**

1. **Research and Compare:** Take the time to compare different models by reading user reviews and specifications. This will provide insights into performance and reliability, ensuring you make a wise purchase.

2. **Consider Used Options:** Look into buying used or refurbished milling machines. Many sell-off reliable products at a fraction of the original cost, but it’s crucial to check the machine's condition and history.

3. **Explore General-purpose Milling Machines:** These machines are versatile and suitable for various materials and projects. Investing in a general-purpose model can save you money in the long run, as it can adapt to multiple tasks rather than needing separate machines.

By keeping these factors in mind, you can find a milling machine that fits your budget without compromising on quality and functionality.

Evaluating Brand Reputation and Customer Reviews for Quality Assurance

When selecting the right milling machine for your projects, evaluating brand reputation and customer reviews becomes crucial for ensuring quality assurance. Well-established brands typically have a history of reliability, performance, and after-sales support, which can greatly influence your purchasing decision. By looking into brands with positive reputations, you can gain confidence that the equipment you invest in will meet your needs and withstand regular usage.

Customer reviews are invaluable resources, providing insights into the real-world performance of milling machines. They often highlight not only the strengths of a product but also its limitations, giving you a balanced view. Reviews can shed light on aspects like ease of use, maintenance requirements, and durability, which are essential factors when considering the machine’s long-term viability. Pay attention to patterns in feedback, as consistent praises or complaints can reveal critical information about the machine's overall quality and user satisfaction. By combining brand reputation with customer insights, you empower yourself to make an informed decision that aligns with your project demands.

Related Posts

-

How to Choose the Right Milling Machine for Your Business Needs

-

What is a Milling Machine and How Does it Work in Manufacturing Process

-

7 Key Benefits of CNC Machines That Can Revolutionize Your Manufacturing Process

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

-

Exploring Innovations in Vertical Machining Centers at the 138th Canton Fair 2025: A Data-Driven Perspective

-

Unlocking Precision: The Essential Guide to 5 Axis Milling Machines for Modern Manufacturing