- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

How to Choose the Right 5 Axis Milling Machine for Your Needs?

Choosing the right 5 axis milling machine can be daunting. Industry expert John Smith states, "Selecting the perfect machine hinges on understanding your specific requirements." This insight is vital for anyone navigating the complex world of milling technology.

5 axis milling machines offer unmatched precision. They allow for multiple angles to be machined in a single setup, saving time and improving accuracy. However, not all machines fit every need. Users must consider factors like material types, production volume, and budget constraints.

Every shop has unique challenges. A machine might excel in one area but fall short in another. A clear understanding of these nuances can lead to better decisions. Remember, the right choice today can impact your efficiency and output for years to come. Evaluation is key; taking time to assess your requirements will always bear fruit.

Factors to Consider When Selecting a 5 Axis Milling Machine

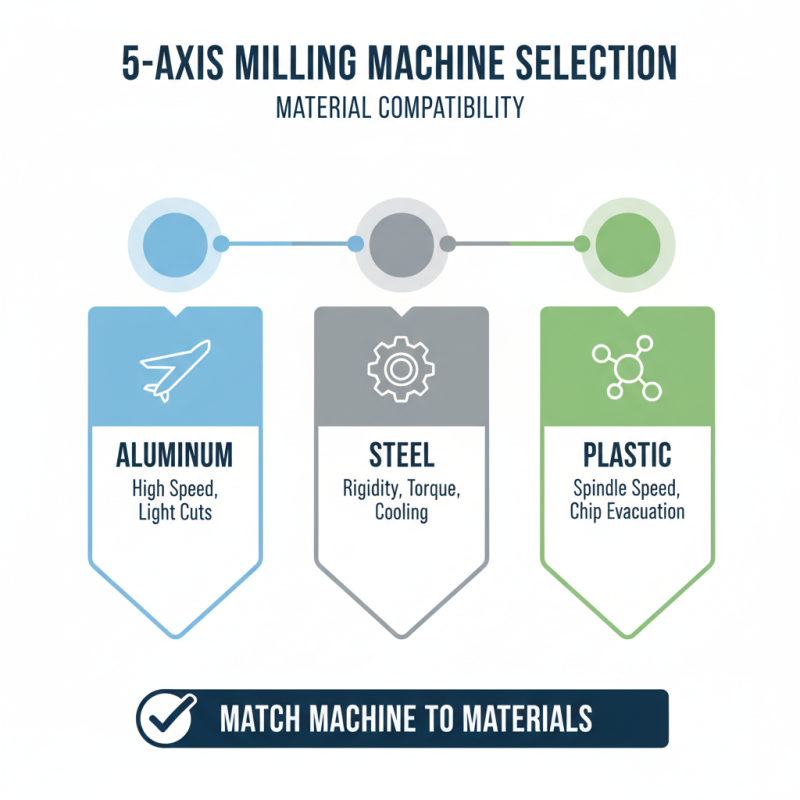

When selecting a 5 axis milling machine, it’s crucial to consider several key factors. Your specific needs play a major role. What type of materials will you work with? Aluminum, steel, or plastic? Each material reacts differently to the milling process. Ensuring the machine can handle your selected materials is vital.

Another factor is the machine's size and workspace. Consider your workshop space. If it’s limited, a compact model might be necessary. Think about the size of parts you will produce. The machine must accommodate these dimensions. Choosing the wrong size can lead to complications.

Technology and features are also important. Look for user-friendly controls. Advanced software can improve precision and efficiency. However, a more complicated interface may require time to learn. This could slow down operations initially. Balance these factors based on your comfort and experience level with technology.

Understanding Different Types of 5 Axis Milling Machines

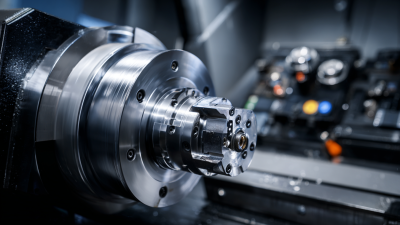

When selecting a 5 axis milling machine, it's crucial to understand the different types available. There are vertical and horizontal configurations. Each type is designed for specific tasks and materials. Vertical machines are often more versatile, accommodating a wide range of milling applications. They excel in producing complex parts with ease.

Horizontal milling machines, on the other hand, are known for their efficiency in bulk production. They generally allow faster chip removal, which can boost productivity. However, they may not be as flexible as vertical machines for intricate designs. Choosing the right type depends heavily on your project needs.

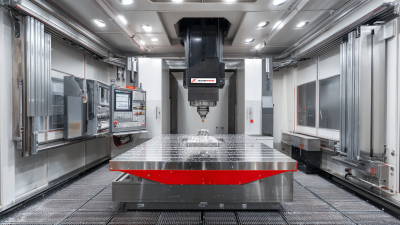

Consideration of size and weight is essential too. Some machines are compact, ideal for small workshops. Others are larger and better suited for industrial environments. Keep in mind that larger machines can handle bigger jobs but require more space. Think about your workspace and production demands before deciding. Smaller setups may limit your options. Reflecting on these factors helps ensure that you choose a milling machine that fits both current and future needs.

Comparative Analysis of 5 Axis Milling Machine Types

Key Specifications to Evaluate for Precision Machining

Choosing the right 5 axis milling machine requires careful consideration of various specifications. Precision is key. You must evaluate the machine’s build quality and rigidity. A sturdy frame reduces vibration, leading to improved accuracy in machining. Observe the spindle speed. Higher speeds often mean faster machining but can affect tool life. Balance speed with the material being processed.

Another important factor is the travel range of the machine. A larger travel range allows for bigger workpieces. Consider the rotary axes as well; they enable complex shapes to be machined with ease. Also, pay attention to the control system. A user-friendly interface can save time and reduce mistakes. However, a complex system may require extensive training.

Look for machines that offer good thermal stability. This aspect greatly impacts repeatability in precision machining. Explore the coolant system; proper cooling can prevent overheating, enhancing tool performance. Remember, no machine is perfect. Some may lack certain features that others offer. Evaluate your specific needs before making a decision. Be prepared to experiment and adjust settings. Each job can be unique, and flexibility is essential.

Assessing Cost-Effectiveness: Budgeting for Your 5 Axis Machine

When budgeting for a 5 axis milling machine, consider both initial costs and long-term expenses. The price tag often reflects its capabilities, size, and brand reputation. Align your choice with what you truly need. A high-end machine can seem tempting, but if it exceeds your requirements, it may not be cost-effective.

Maintenance costs are another factor. Some machines require specific parts or frequent servicing, which can add to your budget. Research these aspects carefully. Potential downtime can impact overall costs. A less expensive machine could potentially lead to delays, affecting profitability. Weigh the pros and cons of each machine carefully. Don't just look at price; assess overall value.

Training is also an expense. Operators may need instruction to use complex milling machines effectively. Budgeting for this training is crucial. Sometimes, it’s more beneficial to invest in a more intuitive, user-friendly machine. Reflect on your workforce skills when choosing. Balancing upfront costs with operational efficiency can be a tough exercise. Be thorough in your evaluations.

The Role of Industry Standards in 5 Axis Milling Machine Selection

Choosing a 5 axis milling machine requires careful consideration of industry standards. Various reports highlight that adherence to these standards can improve operational efficiency by up to 30%. Recognizing ISO 9001 and ANSI standards is critical. These ensure machines meet quality and safety benchmarks.

Many manufacturers often overlook the importance of these guidelines. This could lead to costly mistakes later. For example, a report from the International Society for Precision Engineering mentions that 25% of machines fail due to non-compliance. When selecting a machine, consider the weight and dimensions as well. A machine's footprint must fit your workflow. Dimensions that are slightly off can disrupt operations and lead to inefficiencies.

The material compatibility is another aspect tied to industry standards. Not every machine can handle all materials without compromising quality. The misunderstanding of material limitations can affect production rates. Failure to assess this adequately can add unplanned costs to any project. Recognizing these factors alleviates potential issues and optimizes investment in a milling machine.

Related Posts

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

-

Unlocking Precision: The Ultimate Guide to Machining Centers for Advanced Manufacturing Techniques

-

Unlocking Precision: The Essential Guide to 5 Axis Milling Machines for Modern Manufacturing

-

How to Choose the Best 3 Axis Milling Machine for Your CNC Projects

-

Top 5 Tips for Using a 5 Axis Milling Machine Effectively

-

Understanding the Features of the Best CNC Machining Center for Your Business