- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

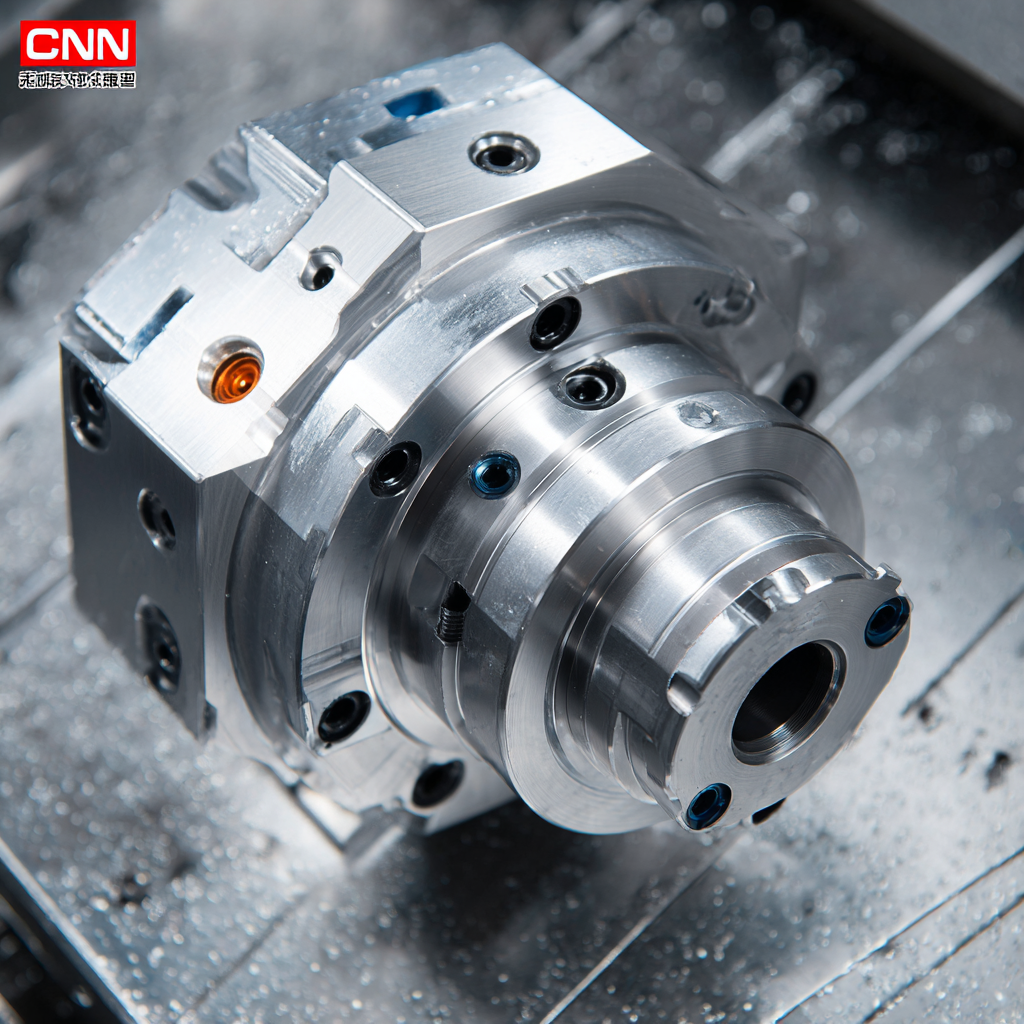

Unleashing China's Premier CNC Machining for Global Market Leadership

As the global landscape for manufacturing continues to evolve, China's commitment to high precision CNC machining positions it as a formidable leader in the industry. With advancements in technology and a focus on innovation, the year 2025 marks a pivotal moment where we can anticipate significant developments and dynamics that will reshape the market. This blog delves into the latest trends, numerical data, and best practices driving China’s CNC machining sector, emphasizing its potential to dominate globally. By exploring these elements, we aim to uncover how high precision CNC machining is not just a skill set, but a critical component in enhancing productivity, reducing costs, and delivering unparalleled quality, ensuring that China remains at the forefront of this competitive landscape.

The Importance of Quality Assurance in CNC Machining Suppliers

Quality assurance in CNC machining is paramount for suppliers aiming to excel in the global market. According to a report from Technavio, the global CNC machining market is expected to grow by USD 4.88 billion from 2021 to 2025, with a compound annual growth rate (CAGR) of over 7%. This growth underscores the increasing demand for precision and reliability in manufactured components, making quality assurance an essential focus area for suppliers.

To ensure high-quality outputs, CNC machining companies are adopting rigorous quality control standards. For instance, the implementation of ISO 9001:2015 certification has been a game-changer, with research by the International Organization for Standardization indicating that certified companies often experience 10% higher customer satisfaction rates. Additionally, industry data shows that 70% of manufacturers highlighted the importance of using advanced quality assurance technologies, such as inline inspection and automated data collection, to minimize defects and maintain consistency in product quality. In a competitive landscape, these practices are not just beneficial but critical for suppliers striving to lead in the CNC machining sector.

Unleashing China's Premier CNC Machining for Global Market Leadership

| Supplier Location | Production Capacity (units/month) | Quality Assurance Certification | Lead Time (weeks) | Customer Satisfaction Rating (%) |

|---|---|---|---|---|

| Shenzhen | 5000 | ISO 9001 | 2 | 95 |

| Dongguan | 7000 | ISO 13485 | 3 | 92 |

| Shanghai | 6000 | IATF 16949 | 4 | 90 |

| Zhengzhou | 3000 | ISO 9001 | 5 | 88 |

| Hangzhou | 4000 | ISO 14001 | 3 | 93 |

Key Factors to Consider When Evaluating CNC Machining Vendors

When evaluating CNC machining vendors, it’s crucial to consider several key factors that can directly impact the success of your manufacturing projects. First and foremost, assess the vendor’s technological capabilities and equipment. State-of-the-art machinery not only enhances precision but also allows for the production of complex geometries that are often required in industries such as aerospace and automotive. Review their certifications and adherence to international quality standards to ensure that their processes meet the highest benchmarks.

Additionally, consider the vendor’s experience and specialization. Vendors with a proven track record in CNC machining for specific industries can offer valuable insights, tailored solutions, and a faster turnaround time. Furthermore, communication and support are vital; a responsive supplier who can collaborate closely with your design and engineering teams will be instrumental in addressing challenges swiftly. Lastly, evaluate their scalability and flexibility to adapt to evolving market demands, ensuring that they can accommodate both large production runs and custom orders as required.

Understanding CNC Machining Market Trends and Their Impact on Supplier Selection

The CNC machining market is currently witnessing transformative trends, driven by technological advancements and increasing demand across various sectors. With the global market for pharmaceutical machinery expected to surpass $25.2 billion by 2024, largely fueled by developments in the biopharmaceutical industry, the role of CNC machining becomes even more pivotal. As industries seek precision and efficiency, suppliers of CNC machinery must align their offerings with the evolving needs of sectors like pharmaceuticals, where accuracy is paramount.

Moreover, the growth trajectory of the CNC machining market is supported by a compound annual growth rate (CAGR) of over 3.9% within the broader context of metal forming machinery. This growth is especially relevant in applications spanning automotive, aerospace, and medical devices, highlighting the importance of robust supplier selection processes. As companies navigate these trends, the need for reliable CNC machining partners capable of meeting the rising expectations of quality and performance is critical for maintaining competitive advantages in an increasingly interconnected global marketplace.

Leveraging Industry Certifications for Credible CNC Supplier Evaluation

In the rapidly evolving landscape of CNC machining, industry certifications play a pivotal role in establishing the credibility of suppliers and ensuring the highest quality standards. According to a report by MarketsandMarkets, the global CNC machining market is projected to reach USD 100.26 billion by 2023, reflecting a compounded annual growth rate (CAGR) of 6.8%. As companies aim for leadership in this competitive arena, leveraging certifications such as ISO 9001 and AS9100 becomes essential for demonstrating adherence to quality management systems and aerospace industry standards, respectively.

The emphasis on certified suppliers not only enhances a company's reputation but also mitigates risks associated with subpar manufacturing practices. A study from Technavio indicates that approximately 20% of all manufacturing defects can be traced back to supplier issues. By prioritizing certified CNC suppliers, organizations can ensure they are partnering with firms that have validated processes and standards.

Furthermore, certifications often provide suppliers with a competitive edge, allowing them to secure contracts in critical sectors such as automotive and aerospace, which demand rigorous compliance and quality assurance measures. As global demand for precision manufacturing continues to expand, the strategic evaluation of certified CNC suppliers will be paramount for achieving sustained growth and market leadership.

Global Supply Chain Insights: Best Practices for Sourcing CNC Machining in China

China has emerged as a powerhouse in CNC machining, positioning itself as a leading source for manufacturers around the globe. Leveraging its advanced technology and skilled workforce, the country offers many advantages when it comes to sourcing CNC machining services. However, navigating the complexities of the global supply chain requires a strategic approach. Understanding the nuances of sourcing in China can greatly enhance efficiency and cost-effectiveness.

To optimize sourcing practices, companies must prioritize establishing strong relationships with Chinese suppliers. Open communication fosters trust and ensures that expectations regarding quality, timelines, and specifications are clearly understood. Additionally, conducting regular audits and site visits can help verify the capabilities of the suppliers. Utilizing local expertise, such as sourcing agents or consulting services, can provide valuable insights into market trends and help overcome potential language or cultural barriers.

Furthermore, leveraging technologies such as digital platforms for real-time tracking and management of CNC machining projects can lead to enhanced transparency and responsiveness. By integrating these best practices into their sourcing strategies, companies can effectively tap into China's robust manufacturing capabilities while ensuring that they maintain a competitive edge in the global market.