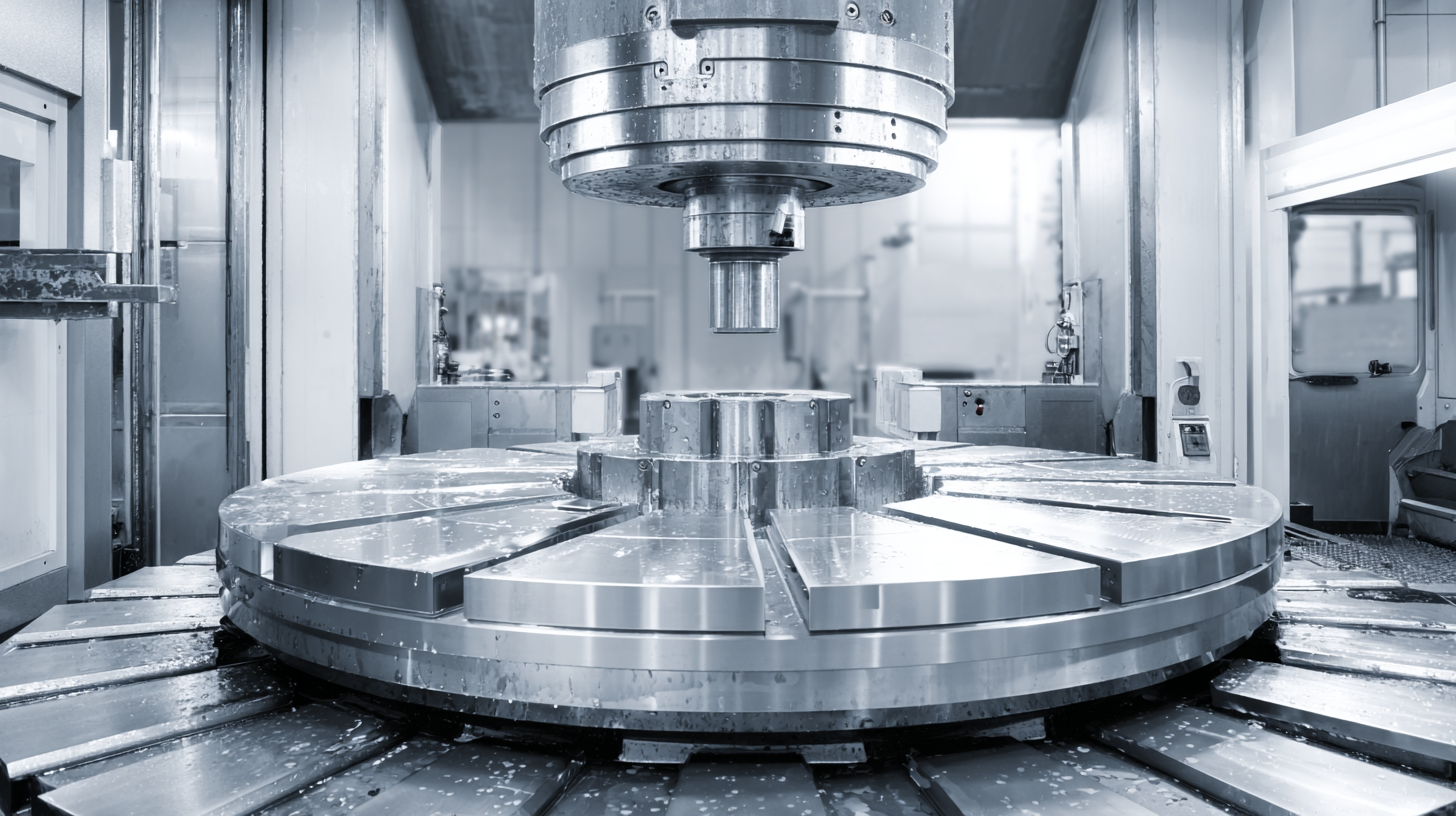

- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Ultimate Checklist for Selecting the Best 5 Axis Machining Services

As industries increasingly demand precision and efficiency, 5 axis machining has emerged as a critical capability in modern manufacturing. According to a report by MarketsandMarkets, the global 5 axis machining market is projected to grow from $2.8 billion in 2022 to $4.0 billion by 2027, reflecting a CAGR of 7.2%. This surge in adoption can be attributed to the technology's ability to enhance production quality and reduce manufacturing time, making it a preferred choice for sectors such as aerospace, automotive, and medical device manufacturing. Given this rapid growth, selecting the right 5 axis machining services is essential for businesses striving to maintain competitive advantage and meet stringent quality standards. This ultimate checklist will guide you in evaluating potential service providers to ensure you partner with the best in the industry.

Key Factors to Consider When Choosing 5 Axis Machining Services

When selecting 5 axis machining services, several key factors must be taken into account to ensure the best fit for your specific needs. First, assess the provider's experience and expertise in handling projects similar to yours. A company with a solid track record often indicates reliability and a high level of skill. Additionally, consider the types of materials they are proficient in machining, as this can impact the quality and precision of the final product.

Another essential aspect is technology. The advancements in CNC machining are significant, with the global CNC machine market expected to grow considerably over the next few years. Therefore, ensure that the machining service utilizes the latest technology and equipment to optimize production efficiency. This can greatly affect turnaround time and cost.

**Tips**: Always ask for samples of previous work or case studies to evaluate the quality of their output. Don't hesitate to inquire about their post-service support as well, since ongoing maintenance and service updates can play a crucial role in the long-term performance of your machined components.

5 Axis Machining Services Evaluation Criteria

The Importance of Quality Assurance in 5 Axis Machining

In the realm of 5-axis machining, quality assurance is paramount to ensuring precision and consistency in manufacturing processes. According to a report by the American Society of Mechanical Engineers (ASME), a staggering 60% of manufacturing defects can be traced back to inadequate quality control measures. This underscores the criticality of selecting a machining service provider that prioritizes strict quality assurance protocols. By implementing methods such as Statistical Process Control (SPC) and real-time inspection, companies can significantly reduce error rates, leading to enhanced product reliability.

Furthermore, a recent study by Deloitte revealed that manufacturers who invest in robust quality assurance systems experience up to a 30% increase in operational efficiency. This highlights not only the importance of quality in 5-axis machining but also its direct correlation with overall productivity. Advanced machining services that encompass quality assurance practices are more likely to meet stringent industry standards, such as ISO 9001 and AS9100, which are essential for aerospace and medical applications. As the demand for precision-engineered components continues to surge, prioritizing quality assurance in 5-axis machining will not only safeguard product integrity but also ensure customer satisfaction and business growth.

Ultimate Checklist for Selecting the Best 5 Axis Machining Services - The Importance of Quality Assurance in 5 Axis Machining

| Criteria | Importance | Quality Assurance Measures | Expected Outcomes |

|---|---|---|---|

| Precision and Accuracy | High | Regular calibration and maintenance of machines | Reduced rework and waste |

| Material Compatibility | Medium | Testing of machining processes on various materials | Enhanced product performance |

| Experienced Technicians | High | Ongoing training and certification programs | Higher overall efficiency |

| Quality Control Procedures | High | Implementation of ISO standards | Consistent high-quality outputs |

| Customer Feedback Mechanism | Medium | Regular surveys and feedback collection | Continuous improvement in services |

Evaluating Cost vs. Value in Machining Services for Global Markets

When selecting the best 5-axis machining services, it’s essential to evaluate the cost versus the value offered by different providers, especially in the context of ever-evolving global markets. The marine collagen market, projected to reach over $1.67 billion by 2024, reflects a growing trend where quality and precision in manufacturing are paramount for maintaining competitive advantage. In this environment, machining services must demonstrate not only lower costs but also superior quality to justify their value to clients.

As industries like food processing and metal cutting expand, with markets expected to grow substantially in the coming years, the demand for advanced machining solutions increases. The global food processing equipment market alone is anticipated to rise to nearly $80 billion by 2032, emphasizing the need for machining services that can keep up with rapid advancements in technology. Companies seeking to optimize their operations must weigh the long-term benefits of investing in higher-quality machining services against short-term savings, ensuring the right balance between cost efficiency and operational excellence.

Innovative Technologies Enhancing 5 Axis Machining Capabilities

Innovative technologies are revolutionizing the capabilities of 5-axis machining, making it an increasingly essential option for a variety of manufacturing sectors. According to a report by Research and Markets, the global 5-axis machining market is projected to reach $3.1 billion by 2025, driven by advancements in automation, precision engineering, and the growing demand for complex geometries in industries such as aerospace and automotive. The integration of tools like advanced CNC software and real-time monitoring systems further enhances machining accuracy and efficiency, allowing for quicker turnaround times and lower operational costs.

Tips: When selecting a 5-axis machining service, consider those that utilize the latest CNC technology and software tools. Ensuring that the vendor you choose employs innovative automation techniques can significantly streamline production processes.

Moreover, companies are increasingly leveraging additive manufacturing alongside traditional machining methods to enhance their capabilities. This hybrid approach not only increases design flexibility but also reduces waste and energy consumption. A 2020 study published in the Journal of Cleaner Production highlighted that the adoption of integrated technologies can reduce material waste by up to 30%, a critical consideration in today’s eco-conscious market.

Tips: Look for services that showcase a commitment to sustainability through technology integration and lean manufacturing practices. This holistic approach not only benefits the environment but can also lead to substantial cost savings for your projects.

Building Long-Term Partnerships with Reliable Machining Service Providers

When selecting a reliable 5-axis machining service provider, it's essential to focus on building long-term partnerships that can enhance your production capabilities. A dependable machining partner will not only meet your immediate needs but also understand your evolving requirements over time. Look for providers who prioritize quality and communication, ensuring that they are responsive and open to feedback.

Tip: Always evaluate a machining service's track record by requesting case studies or testimonials. This can give you insight into their problem-solving capabilities and their commitment to customer satisfaction.

Another key aspect of a fruitful partnership is the provider's investment in technology and resources. Advanced equipment and cutting-edge techniques are crucial for precision and efficiency in machining. When choosing a service, assess their facility and ongoing training programs to ensure they stay updated with industry advancements.

Tip: Schedule a factory visit to observe their operations firsthand. This allows you to gauge their professionalism and the state of their equipment, helping you make a more informed choice.