- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

Choosing the right 3 axis milling machine can be a daunting task, given the vast array of options available in today's market. Whether you're a seasoned machinist or a hobbyist looking to enhance your workshop, selecting the perfect machine is crucial for achieving precise and efficient results. This essential checklist will guide you through the key factors to consider, such as the machine's specifications, versatility, ease of use, and overall build quality. Understanding your specific needs and comparing different models will help ensure that you invest in a 3 axis milling machine that not only meets your current requirements but also adapts to future projects. With the right information at your fingertips, you can make an informed decision that will significantly improve your machining capabilities and productivity.

Understanding 3 Axis Milling Machines: Key Features and Specifications

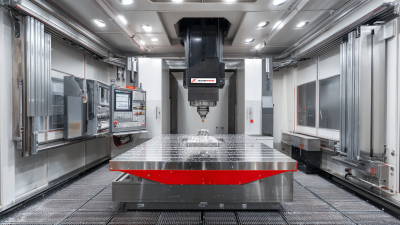

When selecting a 3 axis milling machine, it's crucial to understand the key features and specifications that will best meet your machining needs. The primary aspect to consider is the precision of the machine. Look for milling machines with high-quality spindles and precise linear guides, as these components greatly influence the machine’s ability to achieve tight tolerances and intricate designs. Additionally, the machine's rigidity and stability during operation play a vital role in ensuring consistent performance, especially when working with hard materials.

Another important specification to focus on is the machine's control system. Modern 3 axis milling machines often come with advanced CNC controls that allow for greater flexibility and ease of programming. Features such as user-friendly interfaces, real-time monitoring, and customizable options can enhance productivity and reduce the learning curve for operators. Moreover, the machine's working envelope, including its travel distances and tool capacity, directly affects its versatility and ability to handle various projects. By carefully evaluating these characteristics, you can select a milling machine that perfectly aligns with your operational requirements.

Importance of Precision: The Role of Tolerance Levels in Milling Machines

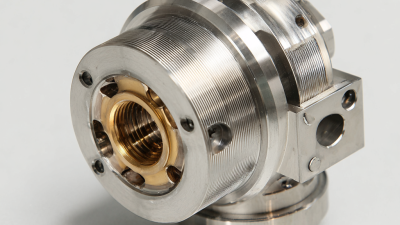

When selecting a 3-axis milling machine, understanding the significance of tolerance levels is crucial for ensuring precision in your work. Tolerance refers to the allowable deviation from a specified measurement, and it plays a pivotal role in achieving the desired accuracy in milling operations. A machine with high tolerance levels allows for tighter control, resulting in components that meet stringent specifications. This is particularly important in industries such as aerospace and automotive, where even the slightest inaccuracies can lead to catastrophic failures or costly rework.

Moreover, the choice of milling machine should align with the precision requirements of your projects. Machines designed with advanced technology often provide superior stability and control, reducing the likelihood of errors during milling. Features such as feedback systems and automatic adjustments can enhance a machine's ability to maintain prescribed tolerance levels. By prioritizing tolerance in your selection process, you can ensure that your milling operations consistently produce high-quality parts that meet your production standards and customer expectations.

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

| Feature | Description | Importance of Tolerance Levels |

|---|---|---|

| Maximum Axis Travel | The distance the cutting tool can travel along each axis | Higher travel allows for larger workpieces, requiring precise tolerances to ensure part accuracy. |

| Spindle Speed | The maximum speed of the spindle, measured in RPM | Optimal speeds vary per material type, requiring precise control to maintain tolerance levels. |

| Tool Change Time | The average time taken to switch tools | Fast tool changes help maintain workflow, necessitating accurate positioning for tolerances. |

| Workholding Precision | How securely and accurately a workpiece is held | Precision fixtures are crucial to ensure that tolerances are maintained throughout the machining process. |

| Coolant System | System used to cool the cutting tool and workpiece | Maintaining a stable temperature helps preserve material characteristics and tolerances during cutting. |

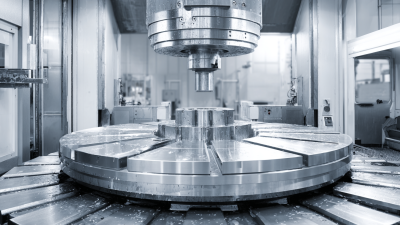

Evaluating the Power and Torque Ratings for Your Milling Needs

When selecting a 3-axis milling machine, evaluating the power and torque ratings is crucial to ensure it meets your specific milling needs. A study on low-power machines, specifically those with power ratings around 10 kW, has highlighted the relationship between energy consumption and the efficiency of cutting mechanisms used in wood size reduction. These findings indicate that the right power specifications can significantly enhance performance, particularly when dealing with various materials that require different energy inputs for optimal processing.

Understanding the no-load power demand is essential, especially in applications where biomass particle size affects handling and conversion processes. Research indicates that the energy consumption patterns of milling machines can vary substantially depending on the design and type of cutting mechanism employed. Choosing a milling machine with the right power and torque ratings not only ensures effective size reduction but also impacts dust control and overall processing efficiency, making it a key consideration in your purchasing decision.

Exploring Control Systems: CNC vs. Manual Milling Machines

When considering a 3-axis milling machine, one of the most critical decisions revolves around the type of control system: CNC (Computer Numerical Control) versus manual operation. CNC milling machines offer unparalleled precision and efficiency by using computer programs to control the movements of the machine. This allows for complex shapes and intricate designs to be reproduced with minimal human error, making CNC a popular choice among industries that require high-volume production and consistency in their parts.

On the other hand, manual milling machines give operators a hands-on experience that can be incredibly beneficial for learning and skill development. With manual control, machinists can develop a keen understanding of the milling process, honing their ability to make real-time adjustments based on their intuition and expertise. This traditional method is often preferred in smaller workshops or by hobbyists who appreciate the tactile feedback and direct engagement with the machinery. Each control system has its advantages, and the choice ultimately depends on the specific needs of the user, production goals, and the complexity of the projects at hand.

Cost Analysis: Budgeting for a Quality 3 Axis Milling Machine & ROI

When investing in a 3-axis milling machine, budgeting is crucial to ensure you obtain a high-quality machine that meets your production needs. According to industry reports, the average price range for a reliable 3-axis milling machine is between $30,000 and $100,000, depending on the specifications and features. A well-calibrated machine can yield a return on investment (ROI) of up to 30% within the first year, largely due to improved accuracy and reduced material wastage.

**Tips:** Always conduct a cost analysis by comparing different machines and their capabilities. Consider not only the initial purchase price but also long-term operating costs, such as maintenance and tooling. Don’t forget to factor in potential downtime costs, as investing in a reliable machine can prevent significant losses.

In addition to upfront costs, think about the potential for upgrades. Many manufacturers offer modular options that allow you to enhance your machine as your business grows. Research shows that businesses that opt for scalable equipment can reduce their future spending by 20% as they adapt to changing market demands. Investing wisely in a 3-axis milling machine can lead to enhanced productivity and increased profits in the long run.

Cost Analysis of 3 Axis Milling Machines

This chart illustrates the cost comparison of different 3 Axis milling machines based on key factors such as initial cost, maintenance cost, and projected ROI over 5 years.

Related Posts

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Ultimate Guide to the Top Five Vertical CNC Machines Compared for Best Performance

-

Unleashing China's Premier CNC Machining for Global Market Leadership

-

Ultimate Checklist for Selecting the Best 5 Axis Machining Services

-

Top Strategies for Sourcing the Best High Precision Machining Solutions Worldwide

-

Understanding Industry Production Standards for Optimal High Speed Machining Performance