- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Discover How Best Precision Machining from China Leads Global Manufacturing Excellence

In the ever-evolving landscape of global manufacturing, precision machining has emerged as a critical driver of efficiency and innovation. With China being a powerhouse in this field, its practices have set benchmarks for quality and productivity worldwide. According to a recent report by Grand View Research, the global precision machining market is anticipated to reach approximately $7.5 billion by 2025, growing at a CAGR of 6.3%. This growth underscores the increasing demand for high-precision components that can meet the rigorous standards of various industries, from aerospace to automotive. As manufacturers seek to enhance operational excellence and reduce costs, understanding how best precision machining from China can lead to unparalleled manufacturing success is essential.

This blog will explore the methodologies, technological advancements, and strategic practices that position China at the forefront of the precision machining industry, contributing to its reputation for global manufacturing excellence.

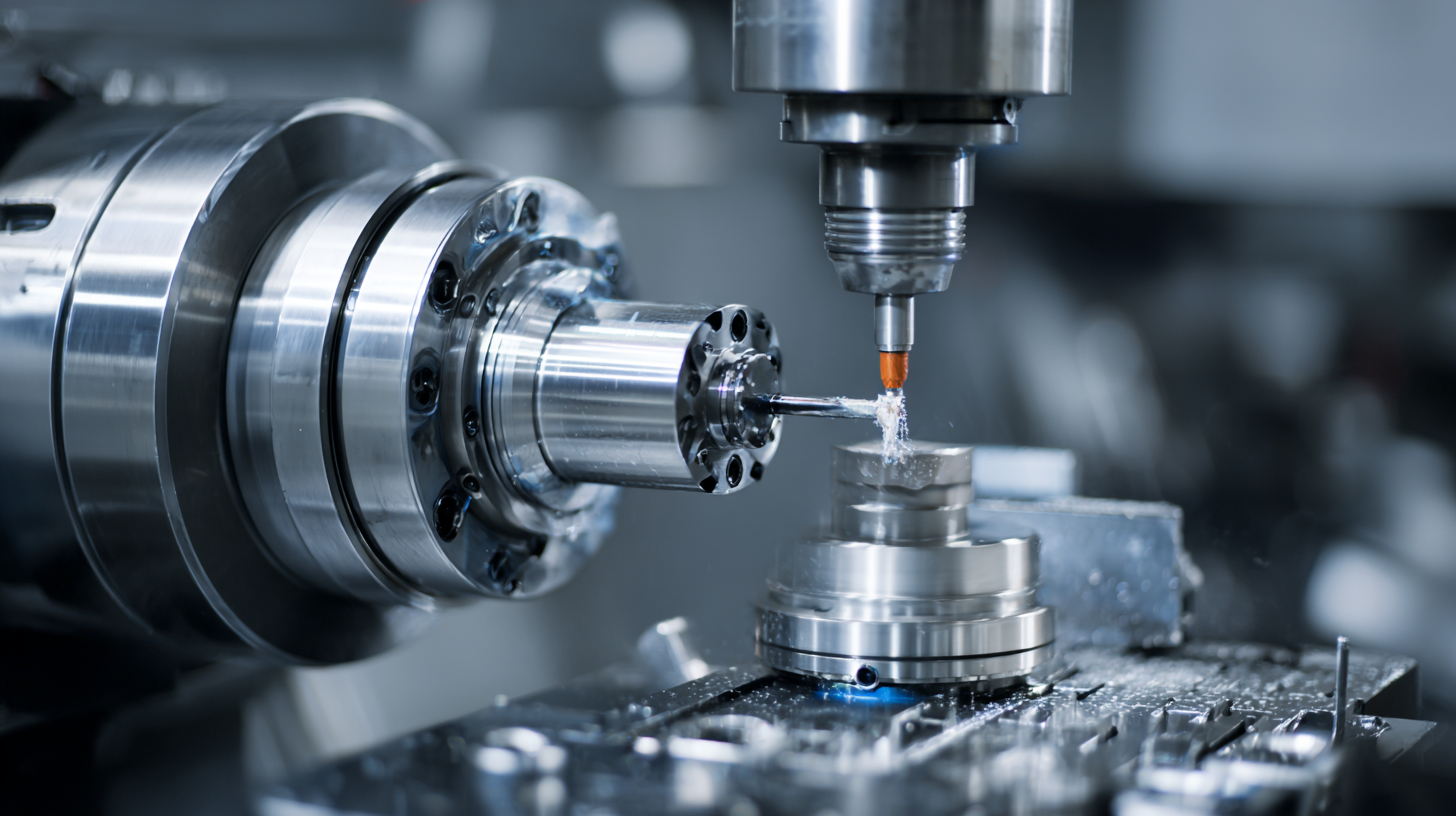

The Role of Precision Machining in Modern Manufacturing Landscapes

Precision machining plays a pivotal role in the modern manufacturing landscape, serving as the backbone of various industries, from aerospace to automotive. With the evolution of technology, precision machining has transformed, incorporating advanced tools and techniques that enhance productivity and accuracy. This evolution allows manufacturers to produce intricate components that meet stringent specifications, ensuring that products not only function effectively but also maintain high safety standards.

China has emerged as a key player in precision machining, leveraging state-of-the-art technology and a skilled workforce to deliver high-quality components at competitive prices. The country's robust supply chain and manufacturing infrastructure allow for rapid prototyping and mass production, making it an attractive hub for companies looking to optimize their manufacturing processes. As global demand continues to rise, China’s precision machining sector is poised to drive innovations that will shape the future of manufacturing, setting benchmarks for quality and efficiency worldwide.

China has emerged as a key player in precision machining, leveraging state-of-the-art technology and a skilled workforce to deliver high-quality components at competitive prices. The country's robust supply chain and manufacturing infrastructure allow for rapid prototyping and mass production, making it an attractive hub for companies looking to optimize their manufacturing processes. As global demand continues to rise, China’s precision machining sector is poised to drive innovations that will shape the future of manufacturing, setting benchmarks for quality and efficiency worldwide.

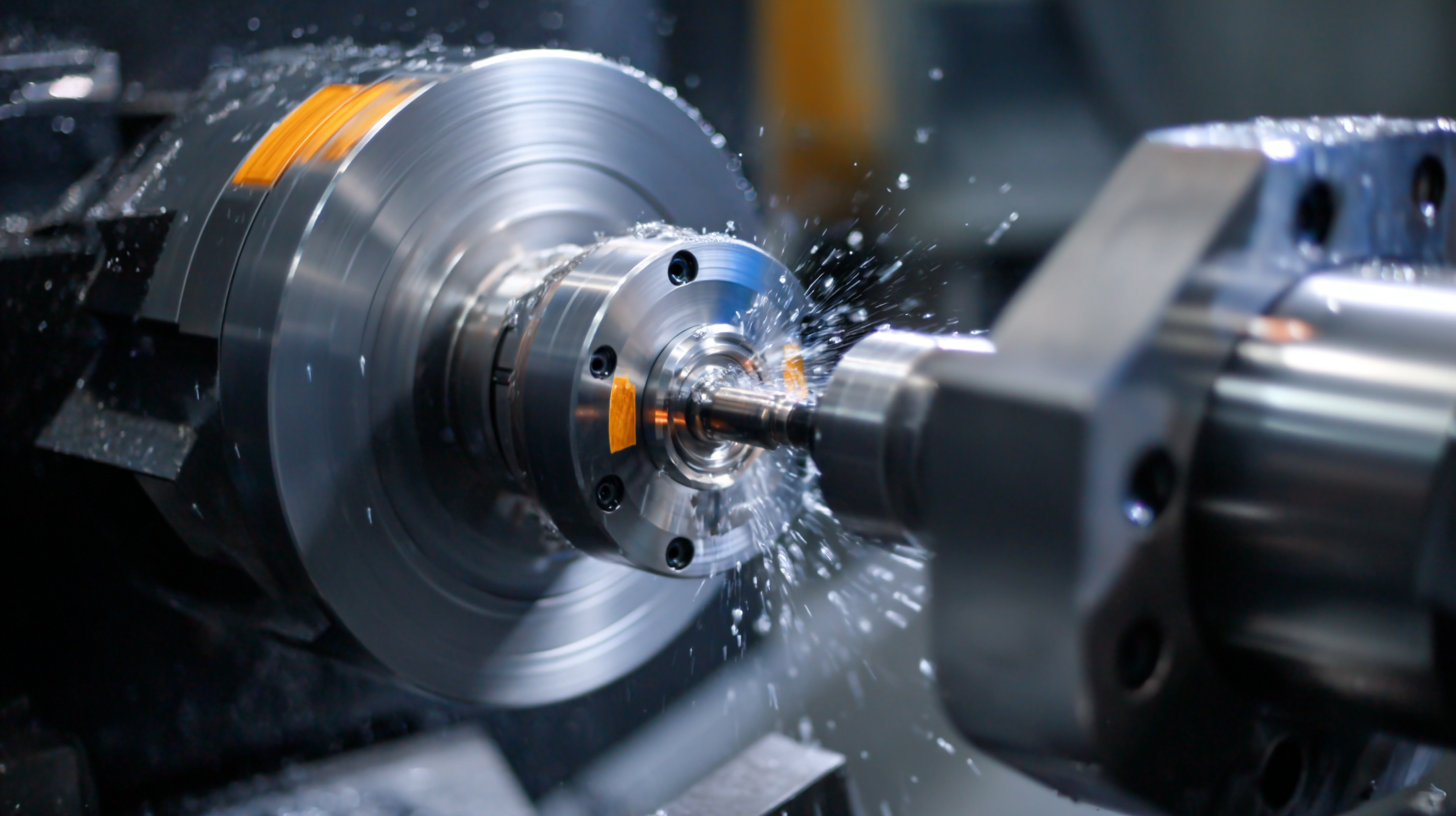

Key Innovations Driving China's Leading Position in Precision Machining

China’s precision machining industry has surged ahead, not merely as a result of low labor costs but through a wave of key innovations that demonstrate its commitment to excellence. From cutting-edge CAD/CAM technologies to advanced automation and robotics, Chinese manufacturers are setting new standards in efficiency and quality. These technologies facilitate highly complex manufacturing processes, enabling the production of intricately designed components that meet rigorous global specifications.

Moreover, the integration of smart manufacturing solutions and data analytics has allowed companies to optimize operations and enhance decision-making. The use of Internet of Things (IoT) devices within the production environment offers real-time monitoring and predictive maintenance capabilities, minimizing downtime and ensuring consistency in product quality.

This technological advancement not only elevates China’s manufacturing capabilities but also positions it as a leader in the global supply chain for precision components, serving industries ranging from aerospace to healthcare.

Challenges and Solutions in Global Supply Chains for Precision Machining

Precision machining has become a cornerstone of manufacturing excellence globally, yet it faces significant challenges within the supply chain. According to a report by MarketsandMarkets, the precision machining market is expected to reach USD 110 billion by 2025, driven by increasing demand across industries such as aerospace, automotive, and medical devices. However, the complexity of global supply chains can hinder manufacturers in meeting this demand, particularly in areas like sourcing quality materials, maintaining timely delivery, and ensuring adherence to stringent regulatory standards.

Moreover, the COVID-19 pandemic has amplified these challenges, with studies indicating that 75% of manufacturing executives reported disruptions in their supply chains. To mitigate these issues, companies are increasingly turning to advanced technologies such as IoT and AI to enhance visibility and traceability in their supply chains. A recent Deloitte report highlighted that organizations that have invested in digital solutions for supply chain management experienced a 15-20% improvement in efficiency. By leveraging these technologies, manufacturers can better navigate the complexities of global sourcing and logistics, ensuring a more resilient and responsive supply chain for precision machining.

Global Supply Chain Challenges and Solutions in Precision Machining

The Impact of Quality Standards on Global Manufacturing Excellence

Quality standards play a pivotal role in the landscape of global manufacturing, especially in the realm of precision machining. As industries become increasingly interconnected, the significance of adhering to stringent quality benchmarks cannot be overstated. In China, manufacturers have embraced international quality standards such as ISO 9001, which foster consistency and reliability in production. This commitment to excellence ensures that products meet the varying demands of global markets, ultimately enhancing competitiveness.

Moreover, the impact of quality standards extends beyond just compliance; they cultivate a culture of continuous improvement and innovation. Precision machining companies in China invest in advanced technologies and skilled labor to maintain high-quality outputs. This proactive approach not only satisfies customer expectations but also drives business growth. As these manufacturers establish themselves as leaders in quality, they contribute to the overall narrative of global manufacturing excellence, demonstrating that meticulous attention to quality is essential for success in today’s complex supply chains.

Future Trends in Precision Machining: China at the Forefront

As global demand for high-quality components continues to rise, precision machining in China is rapidly evolving to meet these challenges, positioning the country at the forefront of manufacturing excellence. According to a report by Grand View Research, the precision machining market is projected to reach $65.69 billion by 2025, with China capturing a significant market share due to its advanced technology and investment in automation. This growth is primarily driven by the aerospace, automotive, and medical industries, which require highly intricate and reliable components.

Moreover, the incorporation of Industry 4.0 technologies, such as IoT and AI, is transforming the landscape of precision machining in China. A McKinsey report highlights that manufacturers adopting these technologies could see productivity improvements of up to 30%. This shift not only enhances efficiency but also fosters innovation in design and production processes. As a result, Chinese manufacturers are not only meeting the rising expectations of global customers but are also setting new standards for precision and quality that are reshaping the future trends in the industry.