- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

In recent years, the global demand for advanced machining technology has witnessed significant growth, particularly in the realm of precision manufacturing. Among these innovations, the 5 axis CNC milling machine stands out as a pivotal solution for enhancing productivity and achieving complex geometries with unmatched accuracy. According to a report from Research and Markets, the global CNC machine market is projected to reach $100 billion by 2025, with a notable portion attributed to the increasing adoption of 5 axis systems due to their efficiency and capability to minimize setup times. This surge is particularly prominent in markets like Asia-Pacific, where countries such as China are upgrading their manufacturing capabilities and delivering high-quality machines that meet international standards. As the "中国制造,品质升级,畅销全球" motto implies, the evolution of Chinese manufacturing in this sector is not only reshaping local industries but also impacting global supply chains, making it essential for international buyers to understand the best options available in the 5 axis CNC milling machine landscape.

Key Features to Consider When Choosing a 5 Axis CNC Milling Machine

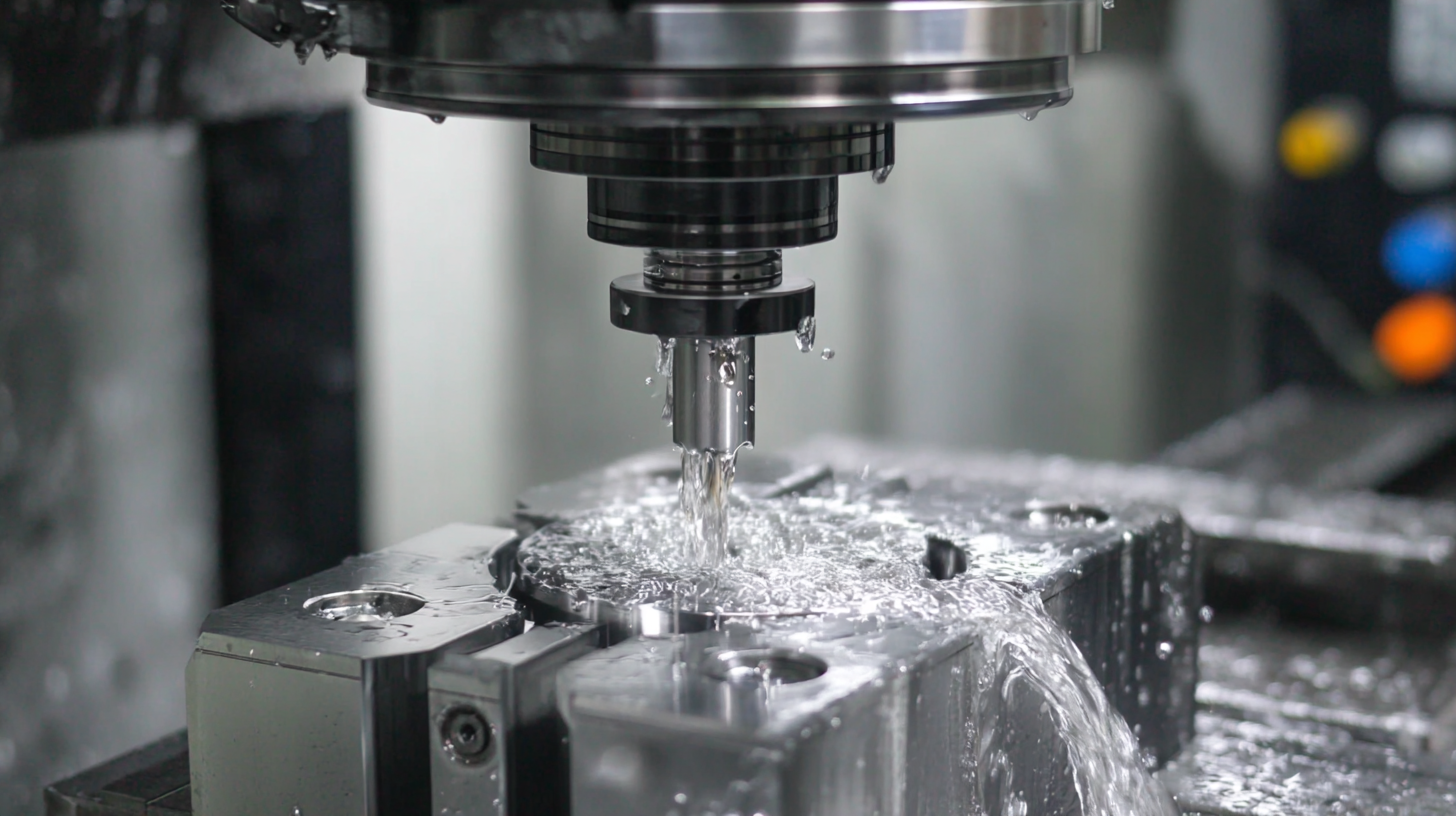

When selecting a 5 axis CNC milling machine, several key features should be meticulously considered to ensure optimal performance and efficiency. First and foremost, precision and accuracy are crucial. A machine that can consistently produce high-quality parts with tight tolerances will not only enhance the end product but also improve production efficiency. Look for machines equipped with advanced motion control systems that minimize errors and enhance repeatability.

Another essential factor is the machine’s rigidity and stability. This directly affects the machining performance, especially when working with hard materials or at high feed rates. A sturdy design will reduce vibrations and increase lifespan while maintaining accuracy. Additionally, consider the machine's software capabilities. Modern CNC milling machines come with sophisticated programming options that can significantly simplify complex tasks and allow for enhanced customization. Lastly, service and support from the manufacturer are vital; ensure that reliable assistance and training are available to maximize your investment. By focusing on these key features, international buyers can make informed decisions when navigating the growing global CNC machine market.

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers

| Model | Max Travel (X,Y,Z) | Rapid Feed (X,Y,Z) | Spindle Speed | Tool Capacity | Weight | Price Range |

|---|---|---|---|---|---|---|

| Model A | 600 x 400 x 300 mm | 30 m/min | 12,000 RPM | 24 tools | 2,500 kg | $50,000 - $70,000 |

| Model B | 800 x 600 x 400 mm | 25 m/min | 10,000 RPM | 30 tools | 3,200 kg | $60,000 - $80,000 |

| Model C | 700 x 500 x 350 mm | 40 m/min | 15,000 RPM | 18 tools | 2,800 kg | $55,000 - $75,000 |

| Model D | 900 x 800 x 500 mm | 20 m/min | 8,000 RPM | 40 tools | 4,500 kg | $70,000 - $90,000 |

| Model E | 500 x 300 x 250 mm | 35 m/min | 14,000 RPM | 12 tools | 1,800 kg | $45,000 - $65,000 |

Top 5 5 Axis CNC Milling Machines for Diverse Manufacturing Needs

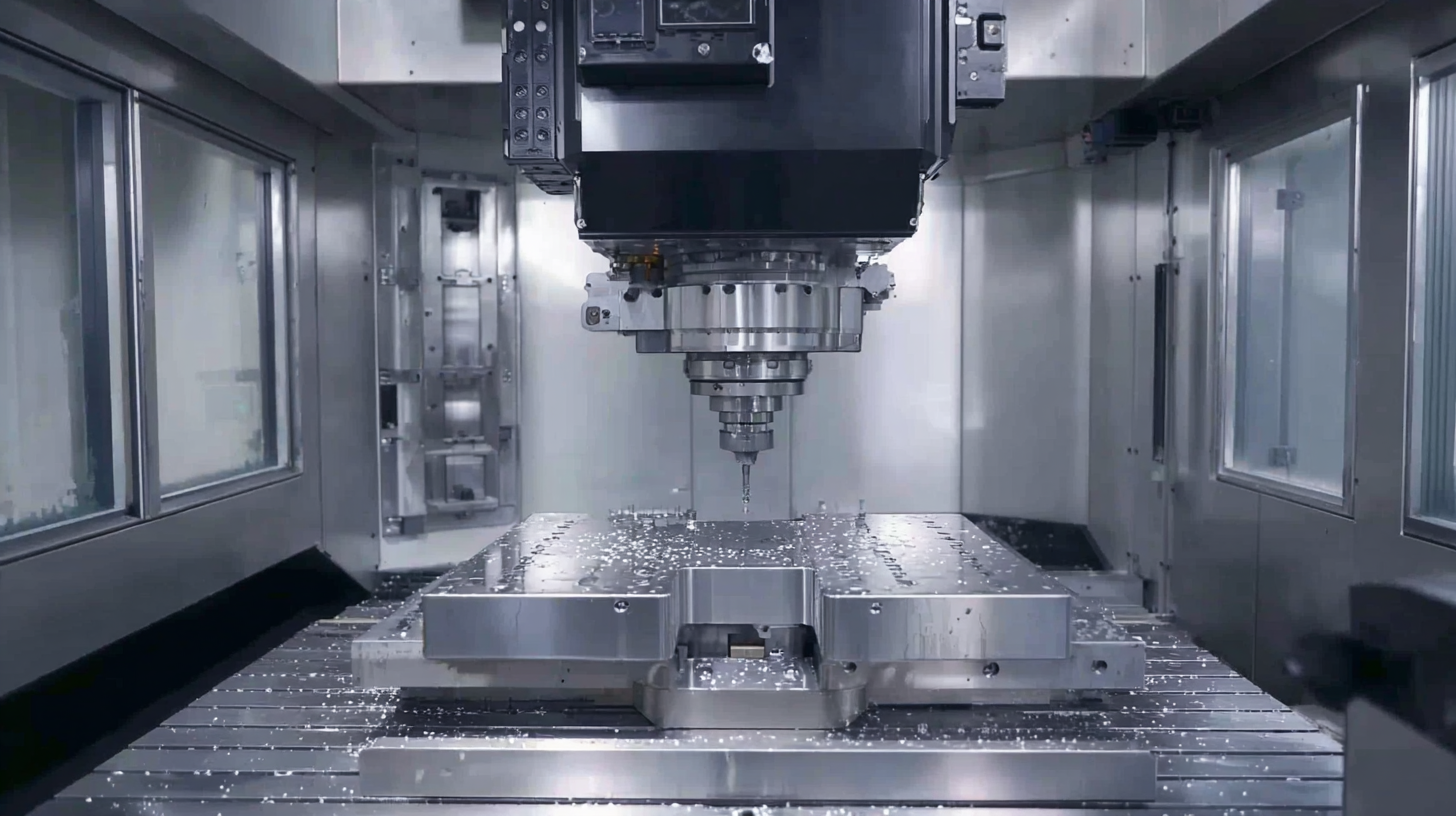

In today's fast-evolving manufacturing landscape, five-axis CNC milling machines have emerged as indispensable tools for meeting diverse production needs. These advanced machines enable manufacturers to create highly complex parts with unparalleled precision, drastically reducing machining time and costs. With the machine tools market projected to surpass USD 105 billion by 2030, the demand for efficient CNC solutions is only set to grow. As industries ranging from aerospace to automotive seek cutting-edge technology, five-axis machines provide the versatility and performance required to stay competitive.

Manufacturers benefit significantly from the capabilities of five-axis CNC milling. These machines allow multi-directional cuts in a single setup, minimizing the need for multiple machine tools and setups, thus streamlining the production process. As companies continue to adopt new digital manufacturing technologies, the role of five-axis machines will expand, addressing increasingly complex fabrication challenges and driving productivity across various sectors. With an anticipated CAGR of 7.5% in the machine tools market until 2034, international buyers must evaluate the top five-axis CNC milling machines tailored for their specific manufacturing needs.

Comparative Analysis of Price and Performance in 5 Axis CNC Machines

When it comes to selecting a 5 axis CNC milling machine, understanding the balance between price and performance is crucial for international buyers. These machines vary greatly in terms of capabilities and costs, making it essential to identify your specific machining needs before delving into the market. For instance, high-end models often offer enhanced features such as faster spindle speeds, greater tool capacity, and advanced software integration, which may justify a higher price tag. In contrast, entry-level machines might serve smaller-scale operations or educational purposes well, while lacking some advanced functionalities.

Tips: Always conduct thorough research on the brands and models available. Look for user reviews and comparison charts to gauge real-world performance. Additionally, consider a machine’s resale value; investing slightly more in a reputable brand can lead to better returns in the future.

Price points are often reflective of the technology and innovations that the machine offers. While some manufacturers design machines focused on affordability, they may provide fewer features or lower precision. Buyers must weigh these factors carefully and consider the long-term implications on productivity and product quality.

Tips: Don’t shy away from discussing your needs with suppliers—they can provide insights tailored to your application. Also, factor in the cost of maintenance and spare parts in your overall budget to ensure a comprehensive evaluation of total ownership costs.

Insights into the Latest Technology Trends in 5 Axis CNC Milling

The landscape of 5-axis CNC milling technology is rapidly evolving, driven by advancements in manufacturing processes and growing market demands. A market research study indicates that the CNC machinery sector is set to see substantial growth, projected to increase from USD 116.32 billion in 2025 to an astounding USD 182.34 billion by 2034. This growth is attributed to the rising need for precision and customization across various industries, including aerospace and woodworking.

In particular, the woodworking CNC tool market is positioned for significant expansion as consumers increasingly seek custom products. This shift is influenced by technological innovations that enhance manufacturing capabilities and efficiency. Furthermore, the CNC rotary table market is also on a growth trajectory, expected to rise from USD 1.5 billion in 2024 to USD 2.8 billion by 2033, reflecting a compound annual growth rate (CAGR) of 7.5%. As manufacturers adopt more sophisticated tools and systems, the integration of high precision machining centers plays a crucial role in driving efficiency and achieving optimal results in advanced manufacturing environments.

Tips for International Buyers: Navigating Import Challenges and Regulations

Navigating the complexities of international trade is crucial for buyers interested in acquiring 5 axis CNC milling machines. With ongoing challenges in supply chains and regulatory environments, it’s essential for buyers to understand the import regulations specific to their target markets. According to a recent report by the World Trade Organization, global trade is experiencing significant transformation, with a notable rise in cross-border e-commerce, which is projected to grow by 26% annually over the next five years. This trend underscores the necessity for buyers to familiarize themselves with both trade laws and logistical considerations when importing machinery.

In regions like Victoria, where certain industries face supply shortages—like the anticipated natural gas shortage this winter—it’s vital for international buyers to approach their purchases strategically. Implementing a thorough market analysis can mitigate risks associated with fluctuating resource availability. Furthermore, understanding the implications of new trade dynamics, such as the shift toward smaller, more agile manufacturing companies, will aid buyers in making informed decisions. Research indicates that smaller firms are increasingly adapting to consumer demands, thereby influencing pricing and availability in the international market. This trend highlights the importance of due diligence in ensuring compliance with international standards and local regulations, ultimately facilitating a smoother import process.