- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

How to Choose the Best 3 Axis Milling Machine for Your CNC Projects

Choosing the best 3 axis milling machine is a crucial step for enhancing the efficiency and precision of your CNC projects. The CNC machining industry has been growing rapidly, with a projected market value of $117 billion by 2026, reflecting an annual growth rate of approximately 6.8% from 2021. This growth is driven by the increasing demand for sophisticated machining capabilities in various sectors, such as aerospace, automotive, and medical devices. As companies strive to meet this demand, selecting the right 3 axis milling machine becomes imperative for achieving optimal performance and reliable results in production processes.

When evaluating various models of 3 axis milling machines, it is essential to consider factors such as accuracy, speed, and build quality. According to a recent report by Grand View Research, technological advancements in CNC machinery are expected to enhance operational efficiencies, which directly translate to increased productivity and cost savings for manufacturers. Furthermore, understanding your specific application requirements can significantly impact your choice. Whether you are working with intricate designs or large-volume production, determining the best machine for your needs is essential for remaining competitive in the evolving landscape of CNC machining.

Understanding the Importance of 3 Axis Milling Machines in CNC Projects

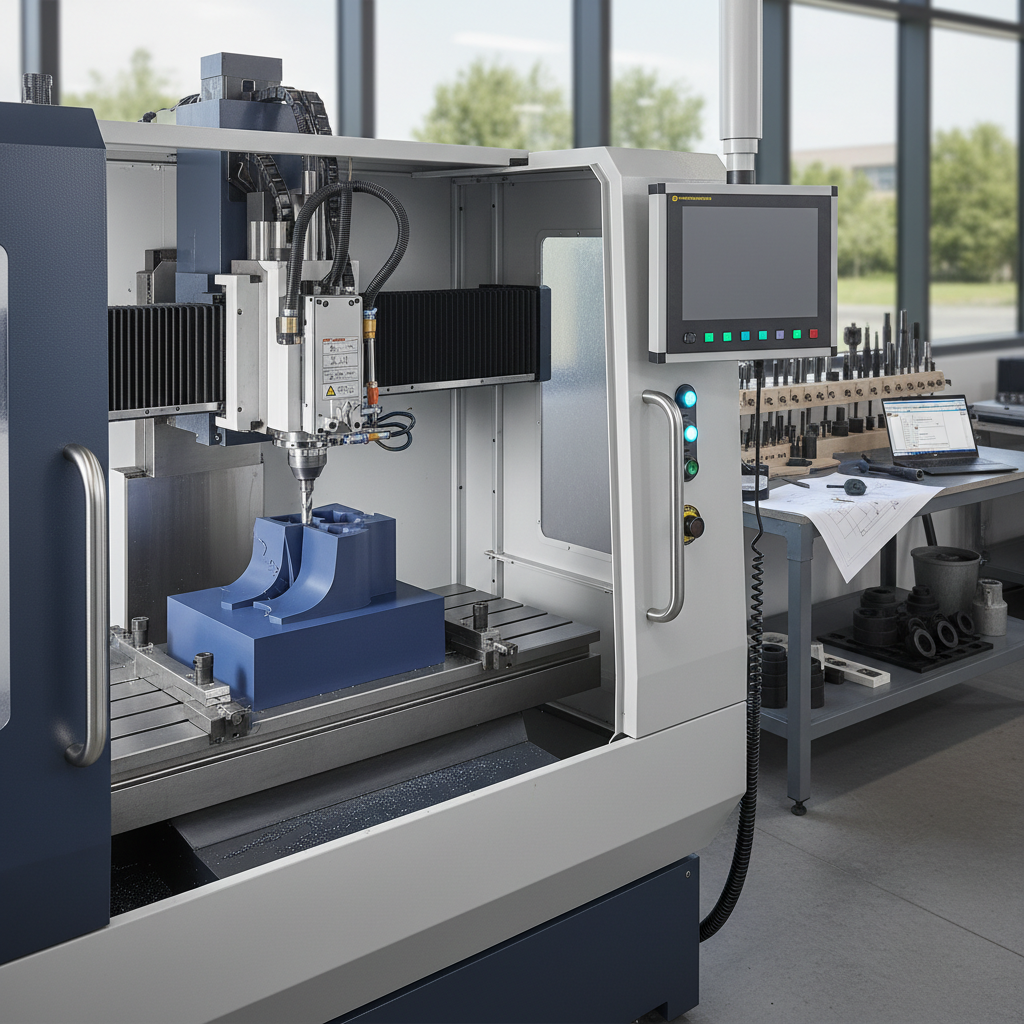

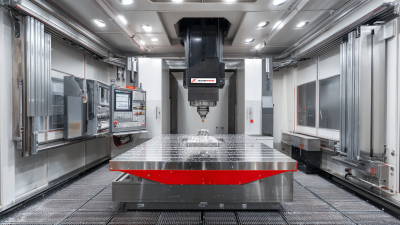

In the world of CNC projects, 3 Axis milling machines play a crucial role in achieving precision and efficiency. These machines operate along three perpendicular axes, allowing for complex shapes and intricate designs to be machined with ease. By controlling the movement of the cutting tool in the X, Y, and Z directions, they enable manufacturers to create detailed components accurately, making them indispensable in various industries such as aerospace, automotive, and electronics.

When selecting the best 3 Axis milling machine for your projects, consider the following tips: First, assess the machine's build quality and rigidity, as this will directly affect precision and durability. Second, look for a model with a versatile spindle speed range, allowing you to handle different materials effectively. Finally, ensure that the machine is compatible with the software you plan to use, as seamless integration can significantly enhance productivity.

Understanding the capabilities of 3 Axis milling machines can greatly influence the success of your CNC projects. With their ability to perform a wide range of operations, these machines not only save time and resources but also increase the potential for innovation in design. By investing in a high-quality machine, you can elevate your manufacturing processes and achieve outstanding results in your projects.

Key Features to Look for in a 3 Axis Milling Machine

When selecting the best 3 axis milling machine for your CNC projects, key features play a crucial role in ensuring optimal performance and precision. One of the most significant aspects to consider is the machine's spindle speed, typically measured in RPM. According to a recent report from the International Society of Automation, higher spindle speeds can significantly enhance cutting efficiency and tool life, enabling you to achieve smoother finishes on complex geometries. A spindle speed of at least 10,000 RPM is often recommended for versatile milling applications, allowing operators to tackle a range of materials, from metals to plastics.

Another essential feature to evaluate is the machine's precision and repeatability, measured in microns. Industry standards denote that a repeatability of ±5 microns ensures that your CNC projects maintain high-quality standards, particularly in the aerospace and medical fields where tolerances are critical. Additionally, look for machines equipped with robust motion control systems and linear guides, as these components are vital for achieving desired accuracy and minimizing wear over time. Reports suggest that machines with high-quality linear guides can reduce friction by up to 65%, resulting in longer operational life and improved performance.

Comparing Different 3 Axis Milling Machine Brands and Models

When selecting a 3 axis milling machine for your CNC projects, it is crucial to compare various brands and models to find the one that best suits your needs. Popular brands such as Haas, Tormach, and Grizzly each offer unique features and price points that cater to different users, from hobbyists to professional machinists. Haas machines are known for their robust construction and advanced technology, making them a favorite in industrial settings. On the other hand, Tormach provides an excellent balance of affordability and functionality, appealing to small businesses and enthusiastic makers.

In addition to brand reputation, it is essential to consider specific model capabilities and user reviews. Some models may offer enhanced precision, while others excel in speed or ease of use. For instance, exploring the specifications, such as spindle speeds and tool compatibility, can reveal how well a machine will perform based on the materials you're working with. User feedback is invaluable as it provides insight into real-world performance and reliability, helping you make a more informed decision in your milling machine selection process.

Evaluating the Cost vs. Value of 3 Axis Milling Machines

When selecting a 3 axis milling machine for your CNC projects, evaluating the cost versus value is essential. The initial investment can vary significantly based on the machine's build quality, features, and brand reputation. Higher-priced models often come equipped with advanced technology, improved precision, and better durability, which can lead to more efficient operations and finer end products. However, it's crucial to assess whether these features align with your specific project requirements and production volumes.

In addition to upfront costs, consider the long-term value of the milling machine. Machines that may appear expensive initially can offer lower operating costs and reduced maintenance needs, ultimately saving you money over time. Features such as high-speed spindles or superior software compatibility may enhance your workflow and productivity, making them worth the investment. Balancing both the immediate financial commitment and the projected benefits is key to making an informed decision that meets your CNC project needs.

Maintenance Tips for Optimal Performance of Milling Machines

To ensure optimal performance of your 3-axis milling machine, regular maintenance is crucial. Start by keeping the machine clean and free from debris that can hinder operation. Dust and chips should be removed from the work area and interior components to prevent wear and tear on the machinery. Regularly inspect and clean the spindle, tools, and other moving parts, as accumulation of dust can lead to overheating and decreased efficiency.

Lubrication is another vital aspect of maintenance. Check and replace lubricants according to the manufacturer’s guidelines, ensuring that all moving parts operate smoothly. Proper lubrication reduces friction and wear, extending the life of the machine. Additionally, keep an eye on the calibration and alignment of the machine components; any misalignment can lead to inaccuracies in machining, affecting the quality of your projects. Regularly checking the machine’s performance against manufacturer specifications will help maintain consistency and precision in your CNC projects.

Related Posts

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

-

Unlocking Precision Engineering with the Power of 3 Axis Milling Machines

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

How to Choose the Right Milling Machine for Your Business Needs

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

-

Unlocking Precision: The Essential Guide to 5 Axis Milling Machines for Modern Manufacturing