- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Top 10 Benefits of Using CNC Milling Machines for Precision Manufacturing?

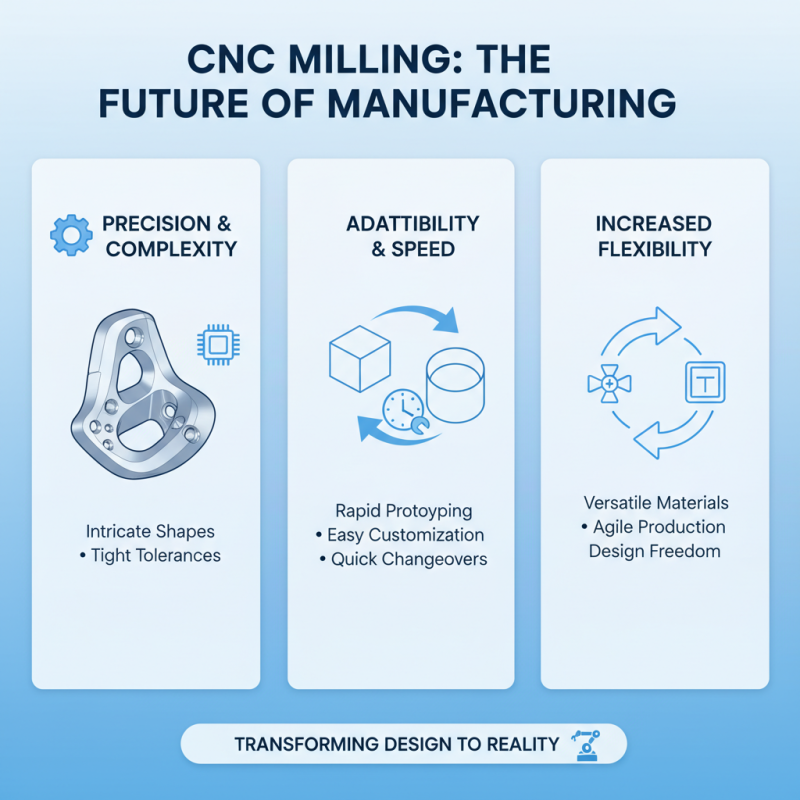

In today’s manufacturing landscape, the CNC milling machine stands as a pivotal tool for precision engineering. Industry reports reveal that CNC milling accounts for over 20% of all machining processes globally. This technology offers remarkable accuracy, significantly reducing the error margin in production. Precision is critical, as just a small deviation can lead to costly reworks.

The benefits of using CNC milling machines extend beyond mere precision. They enhance production efficiency. Research indicates that manufacturers experience up to a 30% increase in output when utilizing CNC milling technology compared to traditional methods. Additionally, the versatility of CNC milling allows for a wide range of materials to be machined, ensuring diverse applications across industries.

However, reliance on CNC technology does present challenges. High initial costs can be a barrier for small businesses. Training employees to operate these machines effectively is crucial but can be time-consuming. Balancing the benefits with these difficulties is essential for manufacturers looking to stay competitive. As industries evolve, the importance of maximizing the potential of CNC milling machines becomes more apparent.

Benefits of Enhanced Precision in CNC Milling Machines

CNC milling machines are revolutionizing precision manufacturing. Enhanced precision is a primary benefit of these machines. In fact, studies show that CNC milling can achieve tolerances as tight as ±0.001 inches. This level of accuracy is crucial in industries like aerospace and medical devices, where precision is paramount.

Manufacturers seeking reliability often turn to CNC milling for intricate designs. The ability to produce complex geometries without compromising quality is significant. Moreover, a report by the International Journal of Advanced Manufacturing Technology indicates that CNC machining has improved productivity by 30% in many cases. However, not every operation utilizes CNC to its full potential. Mistakes can occur in programming, leading to costly errors.

Incorporating CNC technology minimizes human error, yet it’s not foolproof. Operators must be well-trained to handle this sophisticated equipment. Regular maintenance is also vital to sustain precision. Consistent calibration can prevent minor deviations that escalate into major issues. Ultimately, while CNC milling machines offer significant advantages, careful operation remains essential for optimal outcomes.

Top 10 Benefits of Using CNC Milling Machines for Precision Manufacturing

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Enhanced Precision | CNC milling machines provide high precision cutting, allowing for intricate designs to be realized with minimal error. | Improved product quality and reduced waste during the manufacturing process. |

| Increased Efficiency | CNC machines operate continuously and can perform multiple tasks without the need for manual intervention. | Higher production rates and faster turnaround times for projects. |

| Consistent Output | Once programmed, CNC machines produce identical parts without variation. | Ensures uniformity in batches of products. |

| Versatility | CNC milling can work with a variety of materials including metals, plastics, and composites. | Allows for diverse product designs and application across various industries. |

| Reduced Labor Costs | Automation of processes reduces the need for manual labor. | Decreases overall manufacturing costs. |

| Ease of Design Modification | Designs can be altered easily through software without needing new tools. | Facilitates rapid prototyping and innovation. |

| Enhanced Safety | CNC machines minimize human interaction with dangerous processes. | Reduces the likelihood of workplace accidents. |

| Data Monitoring | CNC machines can track and analyze performance data for optimization. | Improves machine efficiency and reduces downtime. |

| Low Material Waste | Precision cutting minimizes excess material usage. | Promotes sustainability by reducing waste. |

| Long-term Cost Savings | Initial investment offsets by lower operational costs and increased productivity. | Increased profitability over time. |

Reduction of Material Waste Through Efficient Cutting Techniques

CNC milling machines revolutionize precision manufacturing by significantly reducing material waste. Traditional machining methods often lead to excess cutting and discarded materials. In contrast, CNC milling uses computer-controlled systems to optimize cutting routes. This precision ensures that only the necessary amount of material is removed, minimizing leftovers.

Moreover, efficient cutting techniques contribute to better resource management. By maximizing the use of raw materials, manufacturers can lower costs. Less waste means spending less on materials and disposal. However, optimizing these processes is not without challenges. Sometimes, operators may need to relearn techniques to fully utilize the technology.

Mistakes can happen, and adjustments are often necessary. It's important to continually analyze the cutting processes. This helps identify areas for improvement. Still, the potential to create intricate designs with minimal waste makes CNC milling a valuable asset in modern manufacturing. Embracing these machines is a step towards sustainability in the industry.

Top 10 Benefits of Using CNC Milling Machines for Precision Manufacturing

Improvement in Production Speed Compared to Traditional Methods

CNC milling machines have revolutionized precision manufacturing. One significant advantage is the improvement in production speed. According to a recent report by the International Journal of Advanced Manufacturing Technology, CNC milling can increase production speed by up to 60% compared to traditional machining methods. This efficiency comes from the automation of processes, reducing manual intervention and eliminating human errors.

Moreover, CNC machines can operate continuously, unlike manual processes that require breaks. A study from the Manufacturing Technology Association highlights that CNC machining can reduce cycle times by 20-30%. This swift operation is vital in industries where time is money. However, it's essential to recognize the initial setup times for CNC milling, which may offset some gains during the early phases of production.

Incorporating CNC milling into manufacturing does require investment in training and equipment. Workers must adapt to operating sophisticated machines. This adaptation often presents challenges, particularly for those accustomed to traditional methods. Still, the potential benefits, like increased accuracy and reduced wastage, often outweigh these initial hurdles. Understanding both the advantages and nuances of CNC milling is critical for maximizing its impact in the manufacturing sector.

Increased Flexibility for Complex Designs and Customization

CNC milling machines are transforming precision manufacturing. One major advantage is their increased flexibility. Designers can create complex shapes with ease. The machines can adapt quickly to different specifications. This allows for rapid prototyping and easy customization of parts.

Intricate designs come to life with CNC technology. Even the smallest details can be carved with high accuracy. Manufacturers can switch between productions without extensive downtime. Customization becomes less of a hassle. However, the learning curve can be steep. Some operators may struggle at first. Understanding the software and machine operations requires dedication.

Every custom request needs careful planning. A minor oversight can lead to significant errors in production. Flexibility is great, but it can also complicate workflows. Operators must remain vigilant and attentive. Balancing creativity with precision is essential for success in this field.

Cost-Effectiveness Over Time in Precision Manufacturing Processes

CNC milling machines have transformed precision manufacturing, especially in terms of cost-effectiveness. These machines automatically control processes with high accuracy, minimizing waste. Over time, they significantly reduce production costs by optimizing material usage. Think about the savings from fewer defects and less rework. Every component produced is likely to fit right the first time, which is crucial for large-scale production.

However, the initial investment in CNC technology can be substantial. Companies must evaluate the trade-off between upfront costs and long-term savings. Not every workshop can afford the latest equipment, which may lead to hesitations or lack of adoption. Yet, for those who do invest, the returns often outweigh the expenses.

Maintenance is another aspect to consider. Proper upkeep ensures efficiency but comes with its own costs. Balancing these factors requires careful reflection.

Moreover, as industries evolve, CNC machines will need upgrades. The pace of technology means that what is state-of-the-art today may need to be reassessed tomorrow. Continuous learning and adaptation are vital in this field. Companies must remain flexible to reap the true benefits of CNC milling machines.

Related Posts

-

Exploring the Impact of CNC Milling on Modern Manufacturing Techniques

-

Ultimate Guide to the Top Five Vertical CNC Machines Compared for Best Performance

-

Understanding Global Industry Standards for Best CNC Machining Precision Production

-

Exploring the Future of Best High Speed CNC Machining Innovations for 2025

-

Ultimate Comparison of the Top 5 CNC Vertical Machining Centers: Performance Metrics and ROI Analysis for Global Buyers

-

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers