- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

Top 5 Tips for Using a 5 Axis Milling Machine Effectively

The advent of the 5 axis milling machine has revolutionized the manufacturing landscape, enabling unprecedented precision and versatility in machining complex parts. According to renowned machining expert Dr. Thomas G. Robinson, "The efficiency and accuracy of a 5 axis milling machine can profoundly transform production capabilities, allowing engineers to push the boundaries of design." This statement encapsulates the essence of utilizing this advanced technology effectively.

Navigating the intricacies of a 5 axis milling machine can be challenging, yet with the right strategies, manufacturers can fully harness its potential. To achieve optimal results, it is crucial to understand the machine's capabilities, programming nuances, and tooling requirements. Operators must be equipped with both knowledge and practical skills to maximize efficiency and minimize downtime. In this guide, we will explore the top five tips that can significantly enhance your proficiency in using a 5 axis milling machine, paving the way for improved productivity and precision in your machining operations.

Understanding the Basics of 5 Axis Milling Machines

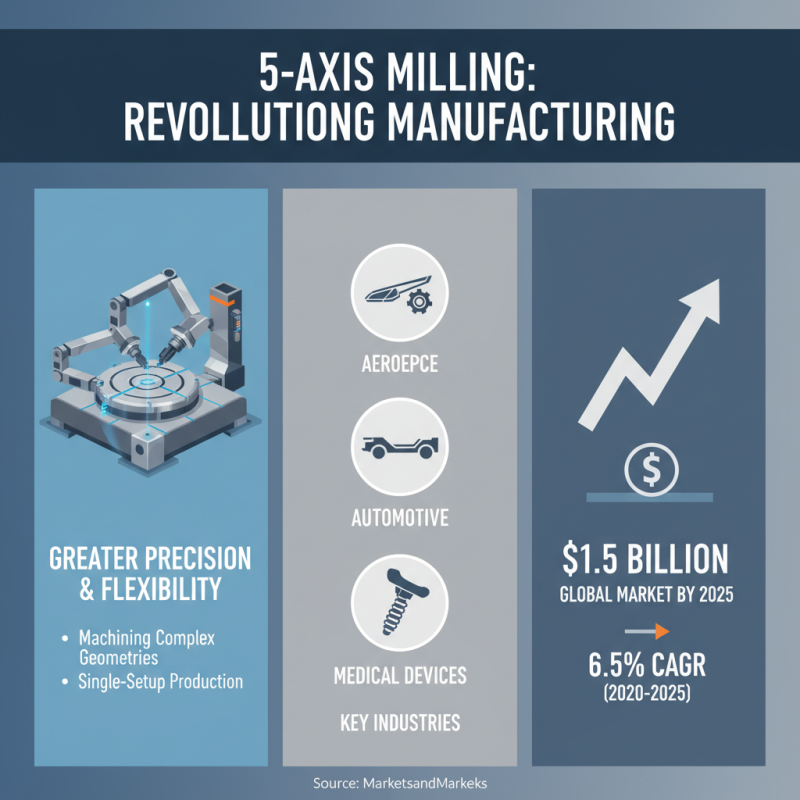

5 axis milling machines are revolutionizing the manufacturing industry by allowing for greater precision, flexibility, and efficiency in machining complex geometries. Unlike traditional 3-axis mills, a 5 axis machine operates with five different movements, offering the ability to cut parts from various angles without the need for multiple setups. This capability is invaluable for industries requiring intricate designs, such as aerospace, automotive, and medical device manufacturing. According to a report by MarketsandMarkets, the global market for 5 axis milling machines is expected to reach approximately $1.5 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.5% from 2020.

Understanding the basic principles of 5 axis milling machines is essential for maximizing their potential. These machines typically consist of three linear axes (X, Y, Z) along with two rotational axes, which significantly enhance the range of motion and the complexity of the parts that can be produced. This multi-axis capability allows for more efficient tool paths, reducing machining time and improving surface finish. Data from the National Tooling and Machining Association suggests that companies utilizing 5 axis technology can reduce setup times by up to 50%, leading to increased productivity and cost savings. With the integration of advanced software that enables sophisticated simulations and real-time adjustments, operators can achieve high levels of accuracy and quality in their manufacturing processes.

Key Features and Benefits of 5 Axis Milling Technology

5-axis milling technology offers significant advantages for manufacturers seeking precision and efficiency. One of the key features is its ability to machine complex geometries without the need for multiple setups. This not only reduces manufacturing time but also minimizes the risks associated with part handling and setup errors. According to a report by Market Research Future, the adoption of 5-axis milling machines in various industries is projected to grow at a CAGR of around 7% over the next five years as more companies recognize the benefits of increased automation and the ability to produce intricate designs in single operations.

To leverage the full potential of 5-axis milling machines, operators should implement a few practical tips. First, proper tooling is crucial: using high-quality, specialized cutters can significantly enhance surface finish and extend tool life. Additionally, regular machine maintenance ensures optimal performance, as wear and tear can lead to diminished accuracy over time. Finally, utilizing advanced CAM software tailored for 5-axis operations can help streamline programming processes, further boosting productivity.

Incorporating these strategies can position manufacturers at the forefront of technology, as 5-axis milling provides exceptional flexibility and efficiency. The ability to produce parts with high accuracy while reducing lead times positions companies to react swiftly to market demands, ultimately contributing to sustained growth in a competitive landscape.

Essential Tools and Equipment for Efficient Milling

When using a 5 axis milling machine, the efficiency of the operation often hinges on the selection of appropriate tools and equipment. A recent industry report indicates that more than 40% of machining time is affected by the choice of tooling, underscoring the importance of investing in high-quality cutting tools and fixtures. Essential tools include solid carbide end mills, which are known for their durability and precise cutting capabilities. Additionally, using advanced tool coatings can significantly increase tool life and improve surface finish, contributing to overall machining efficiency.

To maximize productivity, consider implementing real-time monitoring solutions to track tool performance and wear. Incorporating sensors can provide valuable data, allowing operators to adjust parameters on-the-fly and prevent unexpected downtime. Another critical tip is to utilize proper coolant systems; optimal cooling not only prolongs the life of the cutting tools but also enhances machining accuracy.

Furthermore, consider the setup of workholding devices. Properly securing parts not only improves safety but can also reduce cycle times by minimizing the need for part repositioning. A study has shown that effective workholding can reduce workpiece setup time by up to 30%, thereby streamlining production processes. By focusing on these tools and techniques, operators can ensure that their 5 axis milling machine operates at peak efficiency.

Top 5 Tips for Using a 5 Axis Milling Machine Effectively

| Tip | Description | Essential Tools | Benefits |

|---|---|---|---|

| 1. Proper Setup | Ensure the machine is correctly aligned and calibrated before starting. | Calibration tools, alignment jigs | Increases accuracy and reduces errors. |

| 2. Use Quality Tools | Select high-quality cutting tools suitable for the material. | End mills, tool holders | Improves finish quality and tool lifespan. |

| 3. Optimize Speed & Feed | Adjust speeds and feeds according to the material type. | CNC software, feed rate calculators | Enhances productivity and prevents tool wear. |

| 4. Regular Maintenance | Perform routine checks and maintenance on the machine. | Lubricants, maintenance kits | Increases machine reliability and lifespan. |

| 5. Utilize Advanced CAM Software | Make the most of software capabilities for complex operations. | CAM programming software | Increases machining efficiency and reduces setup time. |

Optimal Setup Techniques for 5 Axis Milling Operations

When setting up a 5 axis milling machine, achieving optimal performance hinges on meticulous preparation. First and foremost, ensure that the workpiece is securely clamped and aligned accurately. Utilizing appropriate fixtures that match the geometry of the part will enhance stability and precision during the machining process. It’s vital to double-check the alignment against the machine’s coordinate system to prevent miscalculations that could lead to costly errors. Additionally, selecting the right tool for the job is essential; factors such as tool diameter and length must be carefully considered to accommodate the multi-directional movements of the 5 axis setup.

Moreover, effective toolpath programming plays a crucial role in the efficiency of milling operations. Utilizing advanced CAM software can facilitate the creation of complex toolpaths that maximize the machine's capabilities. Pay attention to feed rates, spindle speeds, and tool engagement while programming to optimize surface finish and reduce cycle time. Furthermore, implementing real-time monitoring systems can provide immediate feedback on the machining process, enabling prompt adjustments and improving overall productivity. By focusing on these setup techniques, operators can significantly enhance the efficacy and accuracy of 5 axis milling operations.

Top 5 Tips for Using a 5 Axis Milling Machine Effectively

Common Mistakes and How to Avoid Them in Milling Processes

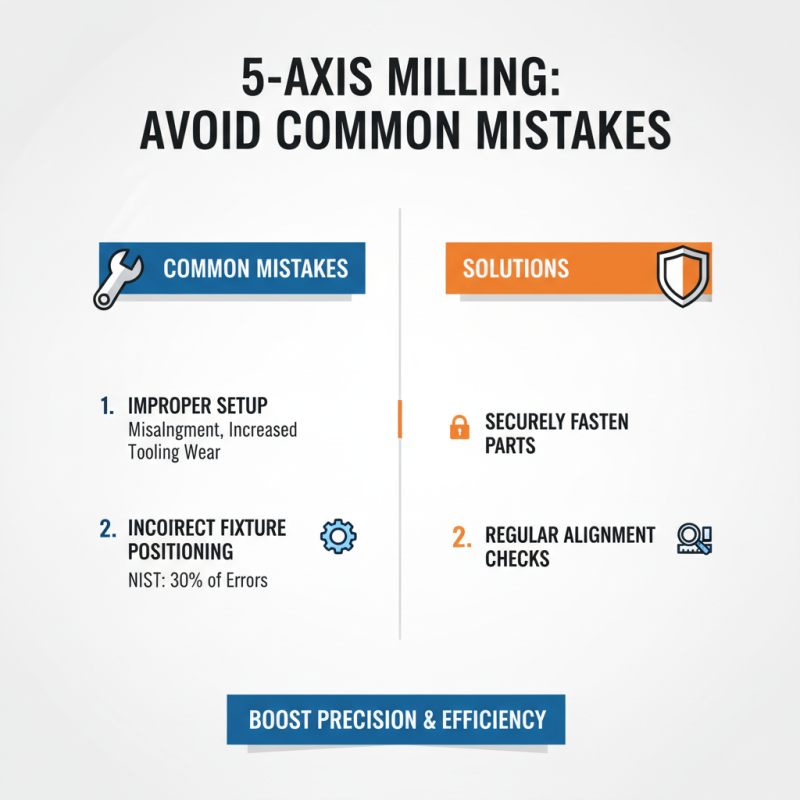

When utilizing a 5-axis milling machine, understanding common mistakes can significantly enhance efficiency and precision in milling processes. One frequent error is improper setup, which can lead to misalignment and increased tooling wear. According to a study by the National Institute of Standards and Technology, nearly 30% of machining errors stem from incorrect fixture positioning. To avoid these issues, ensure that parts are securely fastened and that alignment is regularly checked before starting operations.

Another common mistake is neglecting the feed rate and spindle speed, which can result in poor surface finishes and expedited tool wear. Research from the American Society of Mechanical Engineers indicates that optimizing feed rates can enhance the lifespan of cutting tools by up to 50%. A good practice is to frequently monitor and adjust these parameters based on the material being machined. For example, start with conservative settings and gradually increase them while observing the machining behavior.

Moreover, operators often overlook the importance of proper tool selection. Using inappropriate tooling can lead to suboptimal cutting conditions, increasing the likelihood of tool breakage. A significant percentage of tool failures can be traced back to incorrect choices in both geometry and material. Therefore, it's critical to invest time in selecting the right cutting tools for your specific milling tasks, ensuring you achieve the desired results without incurring unnecessary costs.

Related Posts

-

Understanding the Features of the Best CNC Machining Center for Your Business

-

Ultimate Checklist for Selecting the Best 5 Axis Machining Services

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines

-

How to Choose the Best 3 Axis Milling Machine for Your CNC Projects

-

Ultimate Guide to Best 5 Axis CNC Milling Machine Comparison for International Buyers