- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

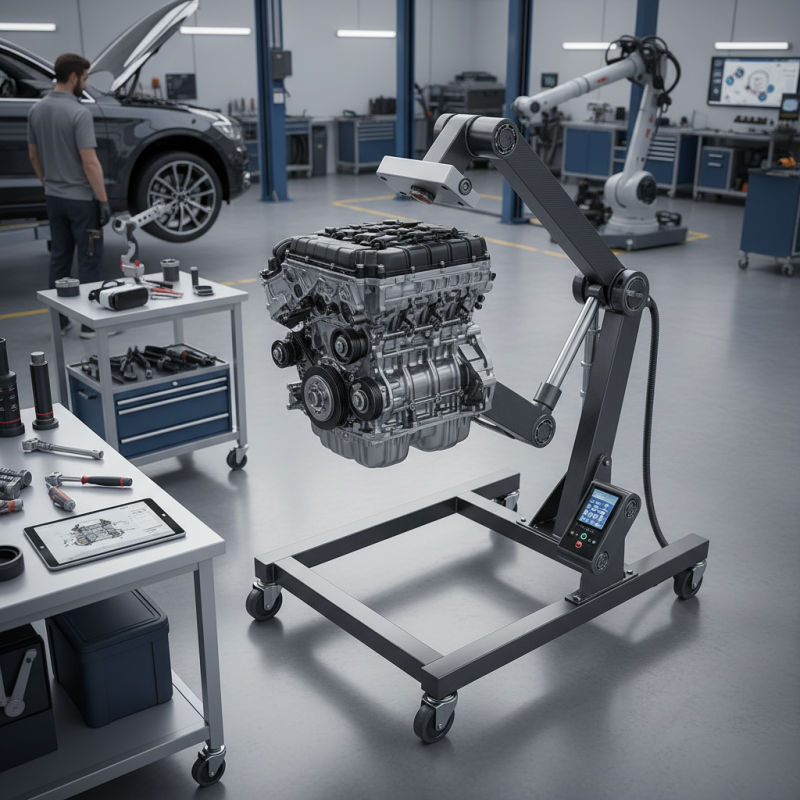

2026 Top Car Engine Stand Features and Benefits Explained?

In the ever-evolving automotive industry, the role of a car engine stand has become increasingly important. Experts like Mark Henderson, a noted automotive engineer, once said, "A good car engine stand is essential for any serious mechanic." This statement emphasizes the value of quality when working on engines.

car engine stands provide crucial support and accessibility when repairing or rebuilding engines. They allow mechanics to rotate and stabilize the engine, making tasks more efficient. However, not all stands are created equal. Some may lack stability or durability, leading to frustration. It’s essential to evaluate features carefully before purchasing this vital tool.

Understanding the key features of car engine stands can save time and enhance repair safety. Proper height adjustment and sturdy construction are vital. Yet, many still overlook these details. This piece will delve into the top features and benefits of car engine stands for 2026, aiming to help buyers make wise choices.

2026 Car Engine Stand: An Overview of Leading Features and Benefits

Car engine stands have evolved significantly by 2026, catering to the needs of enthusiasts and professionals alike. A robust construction is essential. The stability of a stand can prevent accidents during engine repairs.

Many models offer adjustable heights, enhancing convenience. This feature allows users to work ergonomically, reducing strain on the back.

In terms of portability, some designs incorporate wheels. This eases movement around the workspace. However, wheels may compromise stability. Users must ensure the stand is locked in place when in use. The weight capacity also varies. It's vital to match the stand with the engine's weight for safety.

Additional features include compatible engine mounts. They enhance versatility, accommodating various engine types. Despite these advancements, some users report difficulty with assembly. Clear instructions can help mitigate this issue. Identifying which features matter most for your specific needs takes time. Each feature has its pros and cons. Balancing these can lead to better decision-making.

Key Materials Used in Engine Stands: Strength and Durability Insights

When it comes to engine stands, the choice of materials is critical. Steel remains a dominant option due to its strength and durability. Reports indicate that high-carbon steel can withstand heavy loads without bending. It’s also resistant to wear and corrosion. A well-constructed engine stand can last for years.

Aluminum is another popular material, known for being lightweight. It offers decent strength but may not support heavier engines as effectively as steel. The choice often depends on the type of engine being worked on. A balance of weight and strength is necessary.

**Tips:** Consider the weight of your engine when selecting a stand. Check for corrosion resistance to prolong lifespan. Ensure your engine stand’s design offers stability.

Plastic components may exist in some stands. While lightweight, they may compromise strength. Frequent inspections are essential for safety and performance. Don’t overlook small cracks or wear; they can lead to sudden failures. It's vital to choose wisely to ensure your work environment remains safe and effective.

Comparative Analysis of Weight Capacity in Top Engine Stands

When selecting an engine stand, weight capacity is crucial. Many stands support capacities from 1,000 to 2,500 pounds. According to a recent industry report, the average weight of a car engine is around 400 to 600 pounds. This shows that most engine stands can accommodate heavier engines, but not all. For larger engines, a stand with a higher capacity ensures safety and functionality.

The simplicity of usability must match weight capacity. Not all stands offer adequate stability while supporting heavy engines. A stand with a weight limit exceeding the engine weight by 20% is recommended for optimal safety. Many users report concerns over stability. A few stands can wobble or tilt when handling heavy engines. It's essential to consider design features that enhance balance.

Additionally, portable stands are often less robust. They may weigh less but can lack the necessary strength for heavier engines. Careful inspection is vital. Some users overlook the importance of weight distribution. Incorrect placement can lead to accidents. Therefore, understanding weight capacity is not just about numbers; it's about practical application and real-world usage.

2026 Top Car Engine Stand Features and Benefits Explained? - Comparative Analysis of Weight Capacity in Top Engine Stands

| Model | Weight Capacity (lbs) | Material | Height Adjustable | Swivel Casters | Price ($) |

|---|---|---|---|---|---|

| Model A | 1500 | Steel | Yes | Yes | 200 |

| Model B | 1800 | Aluminum | Yes | No | 250 |

| Model C | 1200 | Steel | No | Yes | 150 |

| Model D | 2000 | Cast Iron | Yes | Yes | 300 |

Ergonomic Design: Enhancing Usability and Safety in Engine Maintenance

Proper maintenance of car engines is critical. An ergonomic design in engine stands significantly enhances usability. According to the Automotive Maintenance Association, nearly 30% of engine-related injuries stem from improper handling. Ergonomic features reduce physical strain. This design actively promotes comfortable posture while working on heavy engines.

Adjustable heights and rotating bases are essential features. They allow technicians to work efficiently without bending awkwardly. A recent study showed that ergonomically designed tools can improve productivity by up to 25%. With an easy reach to all engine components, mechanics can complete tasks faster and with less fatigue.

However, even the best tools can pose risks. Users may overlook proper setup, leading to accidents. Regular assessments of workplace ergonomics are necessary. Ignoring minor discomfort can lead to chronic pain. Engaging with these tools mindfully is just as important as the tools themselves. Awareness around ergonomic practices can lead to a safer, more productive workspace.

Cost-Benefit Analysis: Value of Investing in a High-Quality Engine Stand

Investing in a high-quality engine stand is crucial for any automotive enthusiast or professional mechanic. A durable engine stand provides stability and accessibility. According to industry reports, using a well-constructed stand can reduce the risk of damage during engine repairs by up to 35%. This statistic highlights its importance in protecting your equipment.

Cost analysis reveals that spending a bit more initially can lead to better long-term value. High-quality stands often feature adjustable arms, sturdy bases, and are made from durable materials. A premium engine stand can last over ten years with proper care, compared to cheaper models that may need replacement every couple of years. This reality can lead to significant savings over time.

While the upfront cost may seem daunting, consider the potential losses from accidents or inefficiencies. A wobbly engine stand can lead to costly repairs. Investing wisely today means avoiding greater expenses tomorrow. Evaluating your needs allows you to choose wisely. Take your time to reflect on what matters most in your workspace.