- Machining center

- Control

- News & Media

- Company

- Blog

- Contact

2026 Top 3 Axis Milling Machine Innovations and Trends?

In the realm of manufacturing, the 3 axis milling machine is gaining traction for its precision and efficiency. Industry expert Dr. Emily Carter states, “The advancements in 3 axis milling technology will reshape production lines.” As we approach 2026, key innovations are emerging that promise to revolutionize how these machines operate.

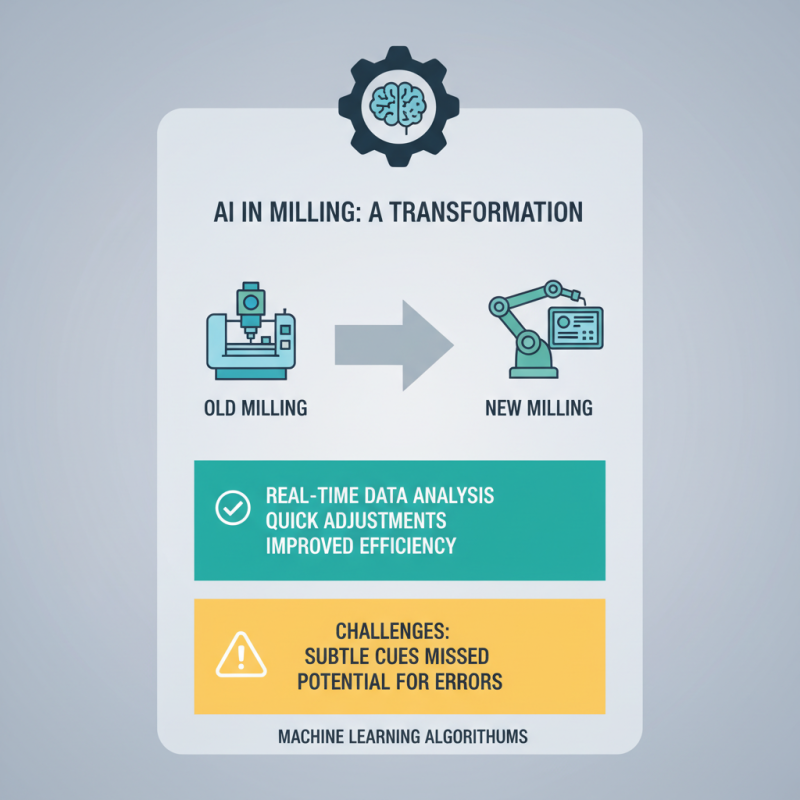

One notable trend is the integration of AI into 3 axis milling machines. This development allows for smarter automation and better decision-making during the milling process. Combined with IoT connectivity, operators can monitor performance in real-time. This ability could reduce downtime and improve output, yet reliance on technology may raise concerns about workforce displacement.

Another trend is the shift towards eco-friendly materials and processes. Many companies are exploring sustainable practices for operating 3 axis milling machines. This focus could lead to less waste and lower carbon footprints. However, transitioning to greener options may pose challenges, such as costs and adapting existing systems. It is crucial for the industry to navigate these complexities for sustainable growth in the coming years.

Top 3 Innovations in 2026 Axis Milling Machines

The milling machine industry is rapidly evolving. In 2026, innovative technologies are reshaping how manufacturers approach machining. One significant trend is the integration of AI and machine learning in milling machines. According to a recent industry report, around 65% of companies plan to implement AI solutions to enhance precision and reduce downtime.

Another notable innovation involves the advancement of multi-axis capabilities. Machines with 5-axis efficiency have increased production flexibility. This allows for complex geometries to be machined in a single setup, enhancing workflow efficiency. Reports indicate that the global market for multi-axis milling machines is projected to reach $4.5 billion by 2026, with a CAGR of 6.8%. Still, many manufacturers struggle with training staff to maximize these advanced capabilities.

Lastly, sustainability is becoming crucial in manufacturing processes. Mills that utilize eco-friendly cutting fluids or energy-efficient designs can significantly reduce operational costs. Industry data shows that up to 40% of manufacturers are prioritizing sustainable practices in their operations. However, transitioning to greener technologies poses challenges, especially regarding equipment compatibility and initial investments. Balancing innovation with practicality remains an ongoing challenge in the milling sector.

Trend Analysis: Smart Technology in Milling Machines

The milling industry is experiencing a transformative phase with smart technology making its mark. Innovations are enhancing efficiency and precision. These advancements are redefining how milling machines operate. Operators now rely on data analytics to improve performance. This shift is significant, introducing real-time monitoring.

Operators can access crucial metrics remotely. This feature assists in predictive maintenance. It minimizes downtime and boosts productivity. With the advancement of IoT, machines can communicate with each other. This connectivity leads to streamlined processes.

**Tip:** Regular training for operators is essential. Familiarity with smart tools enhances performance.

However, it's not without challenges. The integration of smart technology requires substantial investment. Many facilities struggle to adapt. Change can be daunting, and resistance is common. It's crucial for teams to address these concerns.

**Tip:** Start with pilot programs before full adoption. Small adjustments can yield big wins.

Sustainability in Axis Milling Machine Design and Production

Sustainability in axis milling machine design and production is becoming increasingly important. Manufacturers are exploring new materials that reduce environmental impact. Lightweight materials are gaining traction. These choices can enhance efficiency and decrease energy use.

Tips: Consider using energy-efficient components. Evaluate your supply chain for sustainable practices.

Another focus is the reduction of waste during production. Innovations in tooling can lead to better resource management. Implementing closed-loop systems can further minimize scrap. Reality check: not every process is perfect. There are still challenges in integrating these practices.

Tips: Regularly review your procedures. Small adjustments can have big impacts. Sustainability is a journey, not a destination.

2026 Top 3 Axis Milling Machine Innovations and Trends - Sustainability in Axis Milling Machine Design and Production

| Innovation/Trend | Description | Impact on Sustainability |

|---|---|---|

| Energy-efficient Motors | Introduction of motors that consume less power while maintaining high performance. | Reduction in energy consumption and lower carbon emissions during operation. |

| Recyclable Materials | Use of environmentally friendly, recyclable materials in component manufacturing. | Minimizes waste and promotes a circular economy within the manufacturing sector. |

| Smart Manufacturing Technologies | Integration of IoT and AI for real-time monitoring and optimization of machining processes. | Enhances efficiency, thus reducing waste and resource consumption. |

The Impact of AI on Efficiency in Milling Operations

The integration of AI into milling operations is transforming the industry. With machine learning algorithms, these machines can now analyze vast data sets in real-time. This capability allows for quick adjustments during the milling process. However, it’s not always perfect. Sometimes, the algorithms miss subtle cues in the data. This can lead to errors in machining.

AI also enhances predictive maintenance. By monitoring machine health, potential failures can be spotted before they occur. However, this relies heavily on accurate data input. Inaccurate information can skew predictions and result in machine downtime. Operators must remain vigilant and question AI outputs regularly.

Moreover, AI-driven systems optimize production schedules. They can adjust workloads based on demand. But the reliance on AI also raises concerns. What if the data is flawed? There’s a risk of overautomation. Human expertise remains essential, especially in complex decision-making scenarios. Balancing AI efficiency with human oversight is crucial in this evolving landscape.

Future Directions for Axis Milling Machine Technology and Design

The future of axis milling machine technology is evolving rapidly. Innovations will focus on enhanced precision and efficiency. New sensor technologies will provide real-time data on machine performance. This can lead to fewer errors and improved product quality. Smart integration with AI could also play a significant role.

Design trends are shifting towards modular systems. These systems allow for quick adaptations and versatility in production. Some challenges exist since not all machinery can easily transition to this model. Another direction involves sustainability; machines that reduce waste are becoming more popular. Users require machines that are energy-efficient yet powerful.

As these innovations unfold, the need for training rises. Operators must understand the functionality of advanced software. This requires ongoing education and investment in skill development. Not all companies are currently prepared for such shifts. Adapting to these trends could be a challenge, but the potential benefits are vast.

Related Posts

-

How to Choose the Right 5 Axis Milling Machine for Your Needs?

-

Essential Checklist for Choosing Your Perfect 3 Axis Milling Machine

-

How to Choose the Best 3 Axis Milling Machine for Your CNC Projects

-

Top 5 Tips for Using a 5 Axis Milling Machine Effectively

-

Unlocking Precision Engineering with the Power of 3 Axis Milling Machines

-

5 Best Strategies to Maximize Efficiency with 3 Axis CNC Machines